Automatic battery sorting system

An automatic sorting and battery technology, applied in sorting and other directions, can solve problems such as easy jamming, poor equipment stability, and unfavorable speed, so as to avoid jamming and increase the speed of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

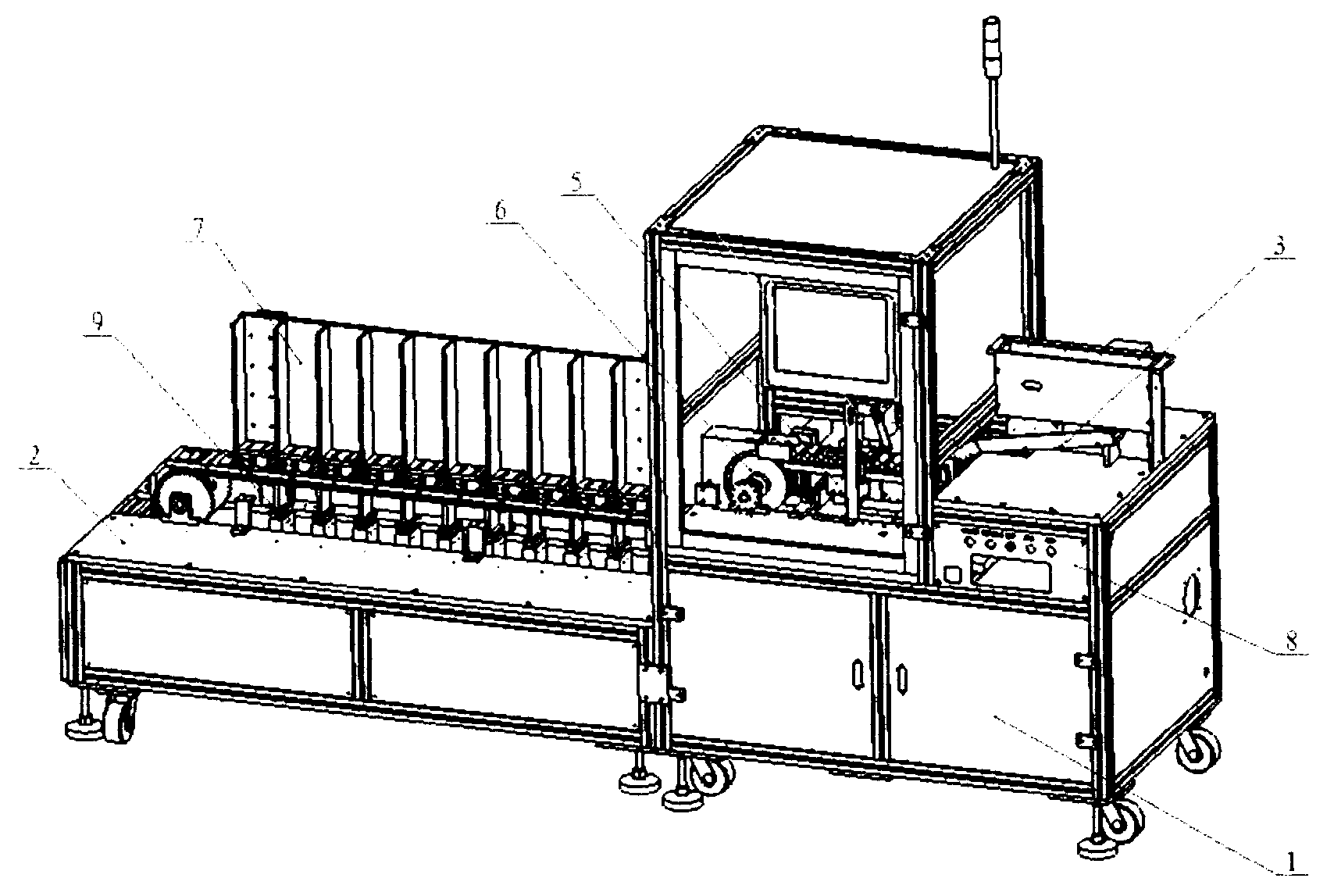

[0035] Such as figure 1 As shown, in one embodiment, the battery automatic rapid sorting equipment includes a frame 1, a substrate 2 installed on the frame, a discharge assembly 3, an identification assembly 4, a kWh assembly 5, a transmission assembly 6, and a battery box assembly 7. Button assembly 8, battery jacking assembly 9 and control system (not shown).

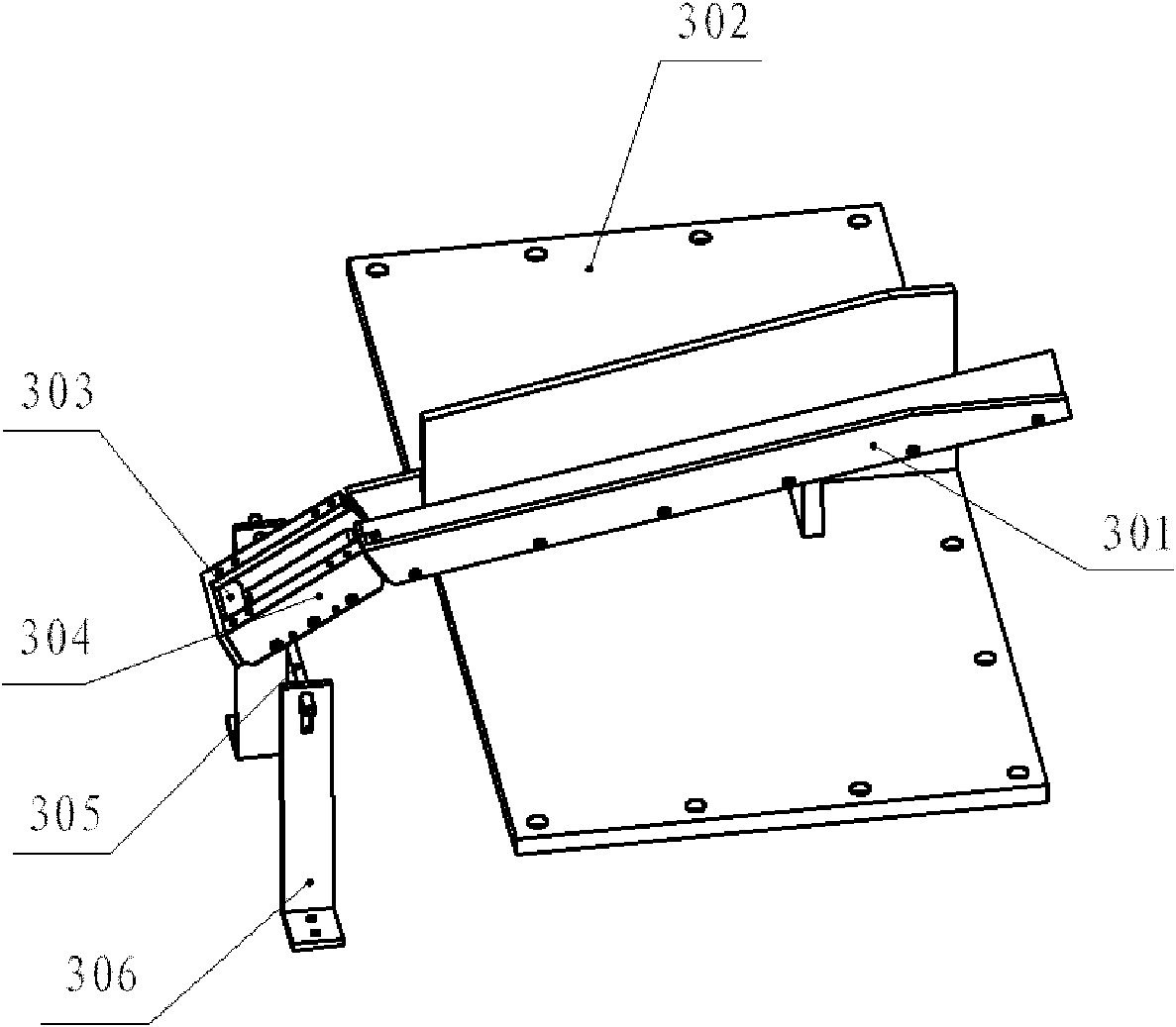

[0036] Such as figure 2 The shown discharging assembly 3 preferably includes a guide plate 301 , a material box bottom plate 302 , a battery 303 , a battery outlet assembly 304 , a screw 305 , and a bracket 306 . The guide plate 301 is installed inclined downwards along the feeding direction. The discharging assembly 3 preferably also includes a lifting rod assembly, which is installed on the discharge end of the guide plate and fixed on the frame base plate for adjusting the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com