Knitting needle for tricot machine

A technology of warp knitting machines and knitting needles, which is applied in knitting, textiles and papermaking, etc. It can solve the problems affecting the installation and positioning of warp knitting machine needle beds, affecting the stability and reliability of knitting needles, and achieves simple positioning Reliable, stable grip and improved fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, a kind of knitting needle suitable for tricot machine:

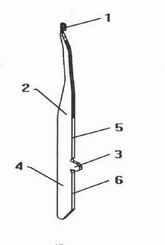

[0016] Refer to attached figure 1 : The designed knitting needle for this warp knitting machine includes needle hook 1, needle bar 2, stitches 3, needle tail 4 and needle bed, and the needle bar is a straight or curved sheet structure, and the needle bar The thickness is consistent, and the front end of the needle bar is provided with a needle hook 1. The needle hook is thin cylindrical, and its diameter is slightly smaller than the thickness of the needle bar. There is a convex stitch 3 in the middle of the needle bar, and the planes 5 and 6 on both sides of the stitch on the same plane.

Embodiment 2

[0017] Embodiment 2, a kind of knitting needle suitable for Raschel warp knitting machine:

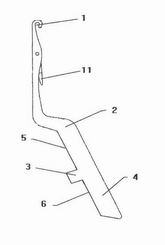

[0018] Refer to attached image 3 , the design of this knitting needle for warp knitting machines includes a needle hook 1, a needle bar 2, a stitch 3 and a needle tail 4. The needle bar is curved and has a sheet structure, the thickness of the needle bar is the same, and the front end of the needle bar A needle hook 1 is provided, and the needle hook is thin cylindrical, and its diameter is slightly smaller than the thickness of the needle shaft; a needle latch 11 is provided at the rear of the needle hook; the length of the needle tail 4 is 1-12 mm, and the width is 2-2 mm. 4mm, the thickness is 0.1-1. 0 mm; there is a convex stitch 3 in the middle of the needle bar, and the planes 5 and 6 on both sides of the stitch are on the same plane.

[0019] When used, (see Figure 4 ) The knitting needles for the warp knitting machine are installed side by side on the needle bed of the war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com