Airtight type electric compressor

An electric compressor, airtight technology, used in machines/engines, liquid fuel engines, mechanical equipment, etc., to achieve the effect of less iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

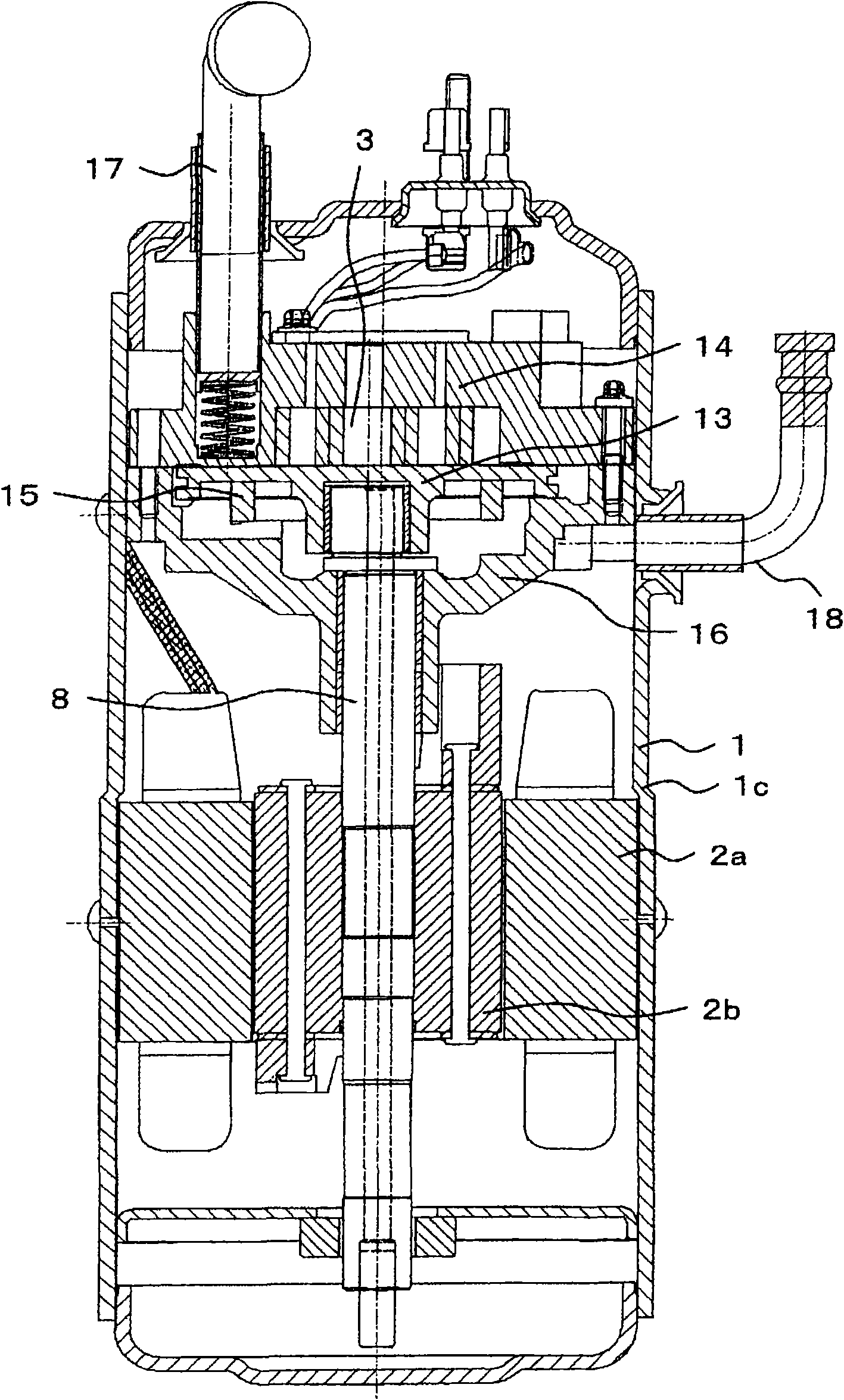

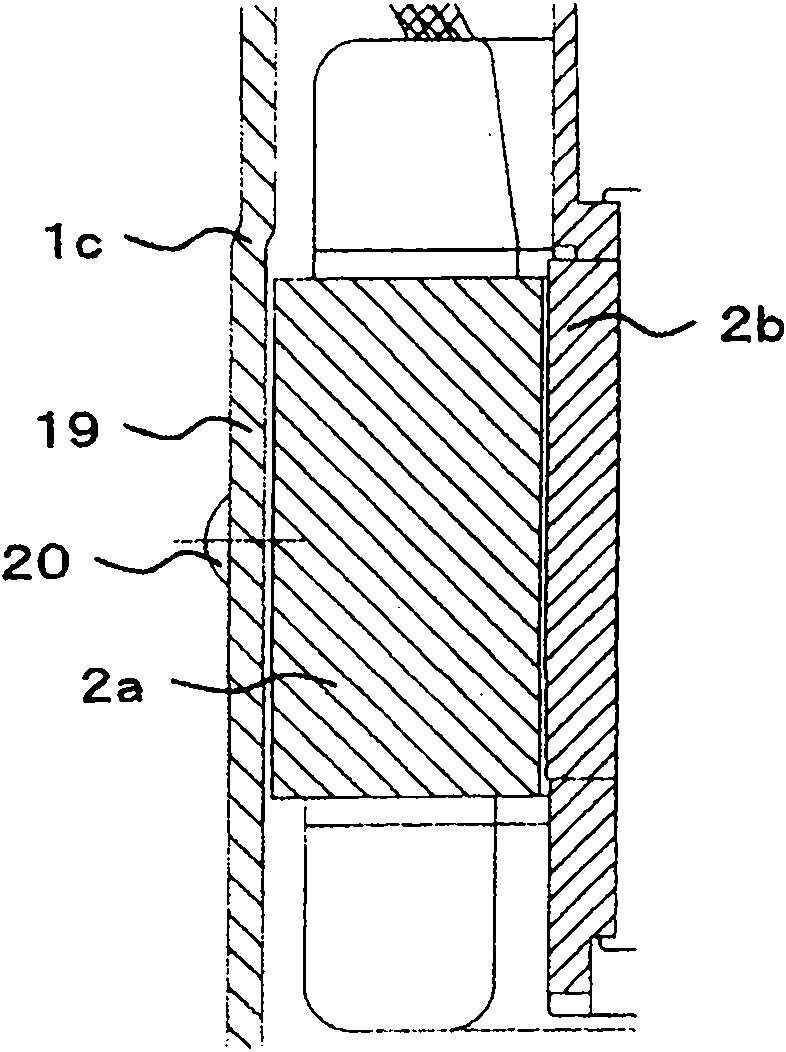

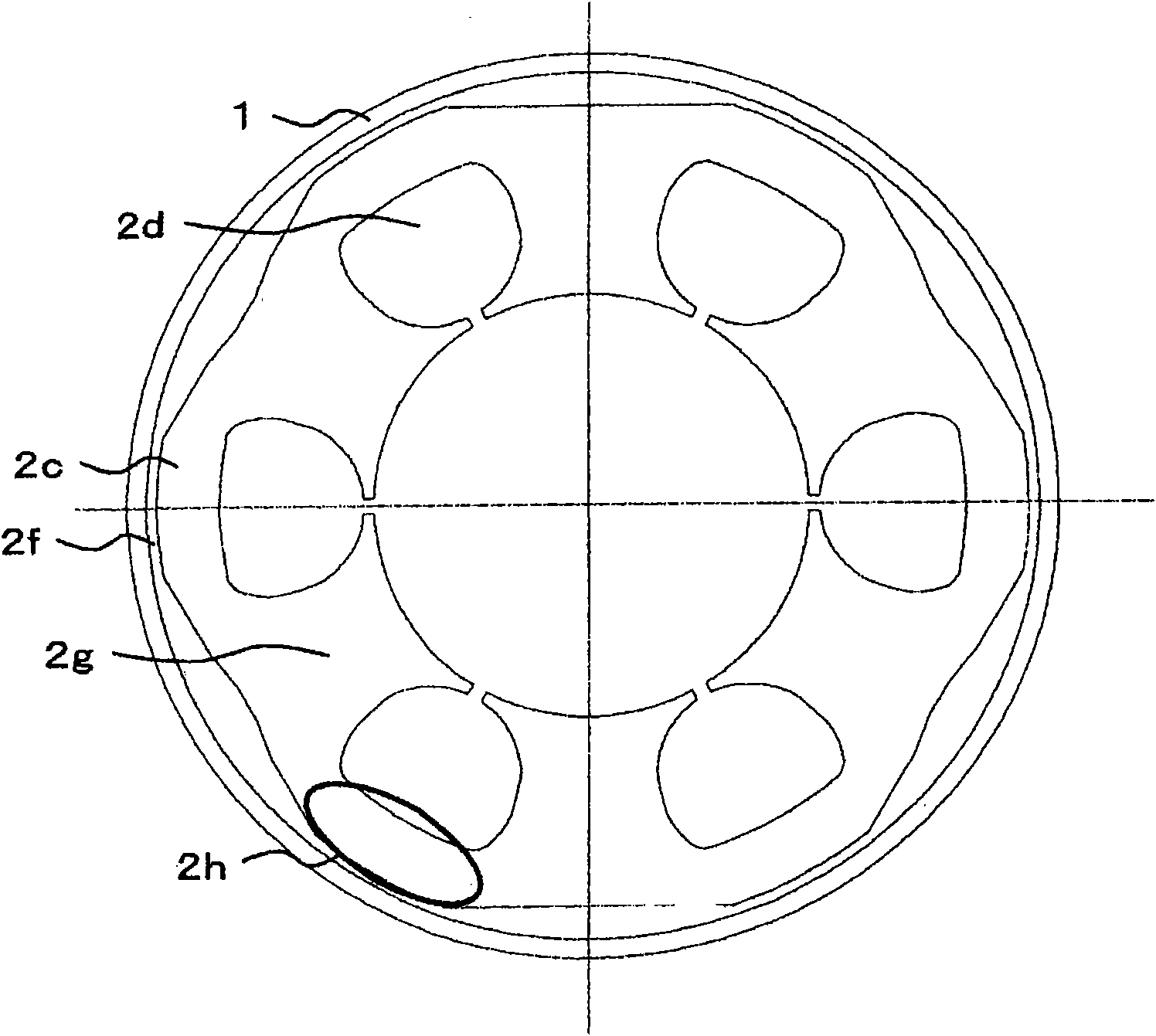

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0041] For the first embodiment, refer to Figure 1 ~ Figure 3 Be explained. figure 1 It is a sectional view of a vertical scroll compressor. As the main structure, a motor 2 which is an electric element and a compression mechanism 3 which is an electric element which compresses the refrigerant between the orbiting scroll 13 and the fixed scroll 14 driven by the electric element are disposed inside the airtight container 1 . The scroll compression mechanism has an Euclid's rotation limiting member that supports and guides between the fixed scroll 14 and the fixed member 16 so that the orbiting scroll 13 performs orbital motion without autorotating relative to the fixed scroll 14 . Ring 15. The motor 2 includes a stator 2 a and a rotor 2 b, the stator 2 a is fixed to the airtight container 1 , and the rotor 2 b is press-fitted and fixed to the shaft 8 .

[0042] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com