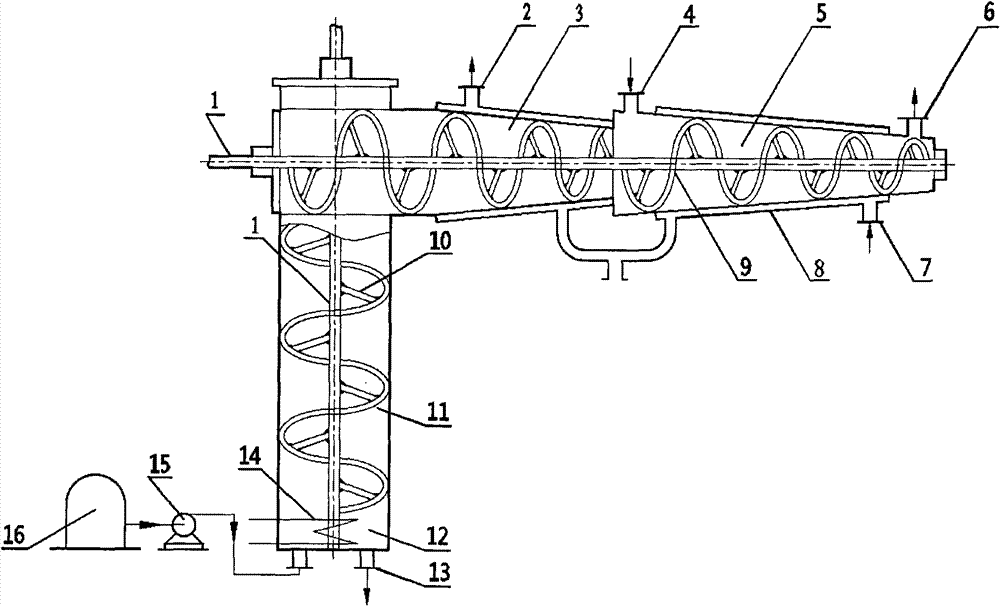

Novel continuous crystallization and purification device

A crystallization device, a new type of technology, applied in the field of new continuous crystallization and purification devices, can solve the problems of poor contact between solid and liquid phases, affecting product purity, unfavorable annual output and benefits of the factory, etc., to achieve a wide range of applications and improve contact state, the effect of preventing channeling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Implementation example: the novel continuous crystallization and purification device announced by the present invention is used to separate naphthalene and thiainene. The height of the purification section in the device is 1.2m, and the lengths of the refining section and the recovery section are respectively 0.6m. The content of naphthalene in the feed is 65% (mass percentage, the same below). Two ways can be used to purify the feed system: one is melting and crystallization, that is, the heating element is used, and the crystal is heated and melted when it reaches the melting section at the bottom of the tower. A part of the liquid is discharged as a product, and the other part is returned to the tower as a reflux liquid. Another kind is solution crystallization, promptly closes heating element, pumps into the bottom of melting section through pumping a proper amount of ethanol from solvent storage tank, and ethanol, thianaphthene and naphthalene crystal carry out coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com