No-hardening flame-retardant transfer coating for magnesium alloy sand casting and preparation method thereof

A technology of sand casting and transfer coating, which is applied in the direction of casting molding equipment, metal processing equipment, coating, etc., to achieve the effect of increasing density, not easy to precipitate, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

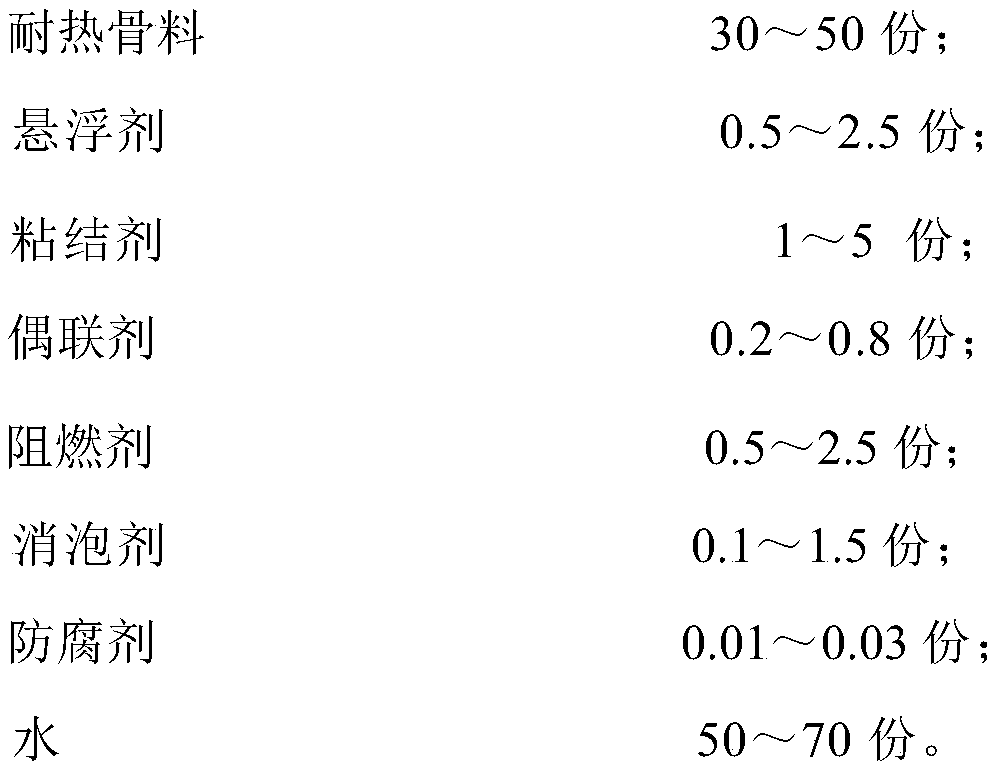

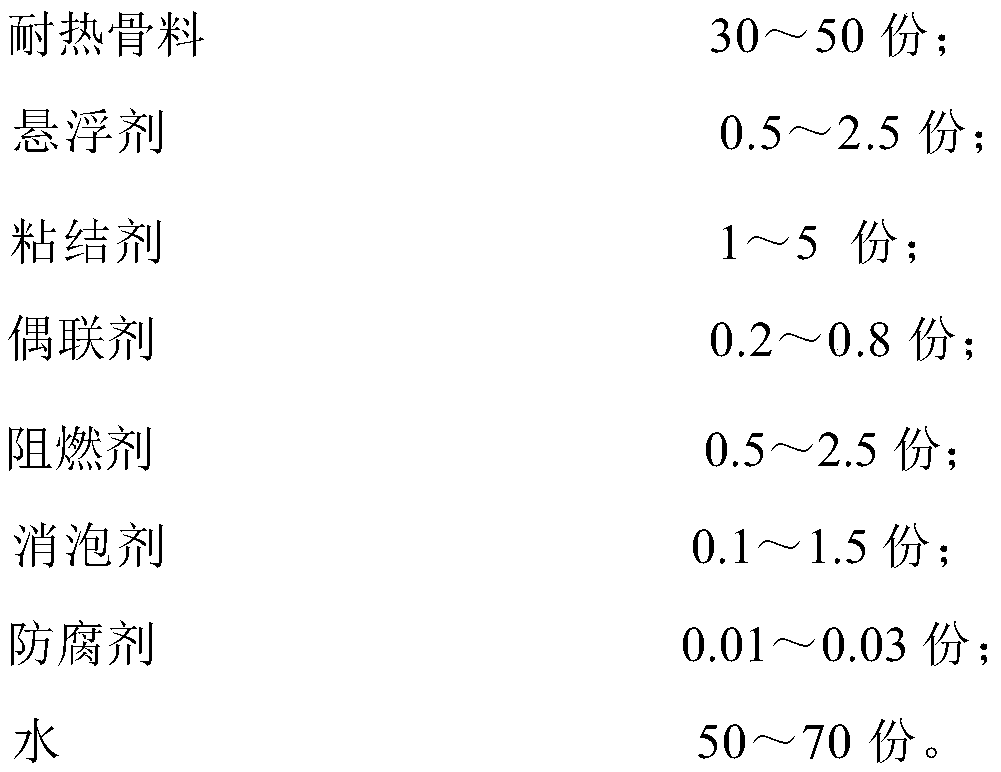

[0066] The following examples also provide a method for preparing a self-hardening flame-retardant transfer coating for magnesium alloy sand casting, comprising the following steps:

[0067] S1. Weigh each raw material component according to the mass percentage;

[0068] S2. Mix the suspending agent with 5-10 parts of water and grind it, then add defoamer and preservative to continue grinding to make liquid A;

[0069] S3. Grinding the flame retardant with 5-10 parts of water to make liquid B;

[0070] S4. Mix the refractory aggregate with coupling agent, binder and 5-10 parts of water and then grind it to make liquid C;

[0071] S5. Mix liquids A, B, and C, add the remaining amount of water, and continue grinding to obtain the no-hardening flame-retardant transfer coating for magnesium alloy sand casting.

[0072] The milling equipment includes a colloid mill or a ball mill.

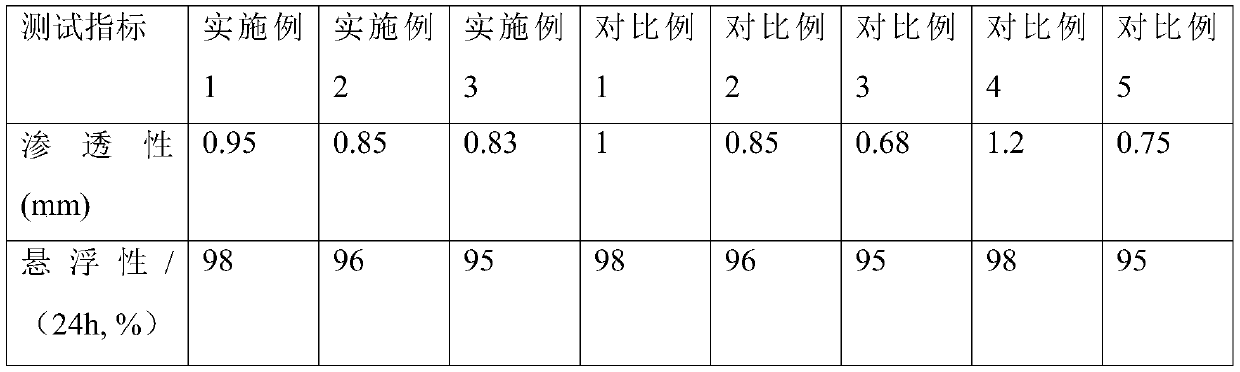

Embodiment 1

[0074] This embodiment provides a method for preparing a self-hardening flame-retardant transfer coating for magnesium alloy sand casting, comprising the following steps:

[0075] raw material:

[0076] The refractory aggregate with the following ratio is 25 parts of corundum powder, 20 parts of magnesium oxide powder, and 5 parts of graphite powder; the suspending agent is 1 part of sodium bentonite, and 0.25 parts of attapulgite; 2 parts of urea-formaldehyde modified furan resin binder 0.5 part of coupling agent; 0.5 part of flame retardant (including boric acid 75wt%, ammonium fluoroborate 6wt%, sulfur 19wt%); 0.3 part of organic silicon defoamer; 0.01 part of sodium pentachlorophenate preservative;

[0077] Preparation:

[0078] 1. Mix the weighed suspending agent with 5-10 parts of water and grind it in a colloid mill or ball mill for 0.5 hour, then add defoamer and preservative to the liquid and continue grinding for 1 hour to make liquid A, and mix A good solution is ...

Embodiment 2

[0086] This embodiment provides a method for preparing a self-hardening flame-retardant transfer coating for magnesium alloy sand casting, comprising the following steps:

[0087] raw material:

[0088] The refractory aggregate with the following ratio is 15 parts of corundum powder, 15 parts of magnesium oxide powder, and 10 parts of graphite powder; the suspending agent is 1 part of sodium bentonite; 5 parts of urea-formaldehyde modified furan resin binder; 0.8 parts of coupling agent 1.5 parts of flame retardant (including 75wt% of boric acid, 6wt% of ammonium fluoroborate, 19wt% of sulfur); 1.5 parts of organic silicon defoamer; 0.03 part of sodium pentachlorophenate preservative; 70 parts of water.

[0089] Preparation:

[0090] 1. Mix the weighed suspending agent with 5-10 parts of water and grind it in a colloid mill or ball mill for 0.5 hour, then add defoamer and preservative to the liquid and continue grinding for 1 hour to make liquid A, and mix A good solution is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com