Microelectromechanical z-axis detection structure with low thermal drifts

A technology of displacement and orthogonal axes, which is applied in the field of micro-electromechanical z-axis detection structure, and can solve problems such as offset drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

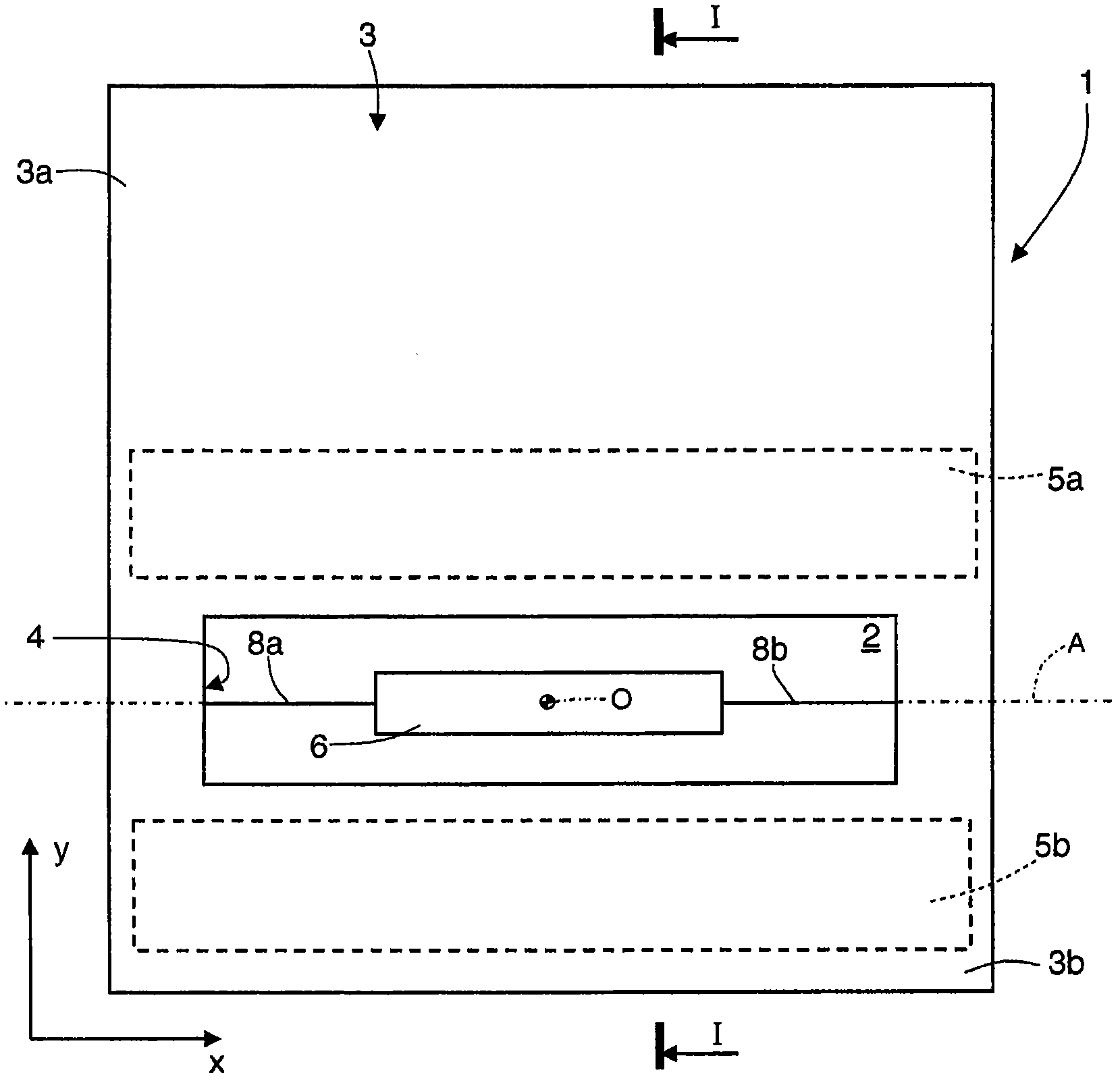

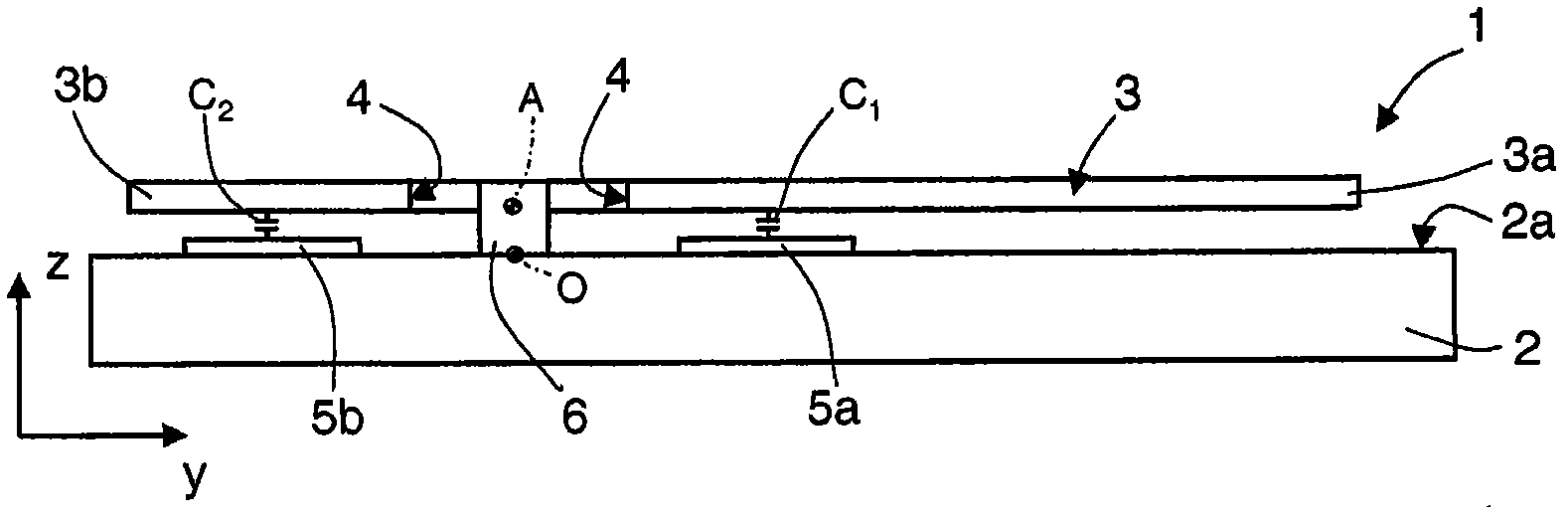

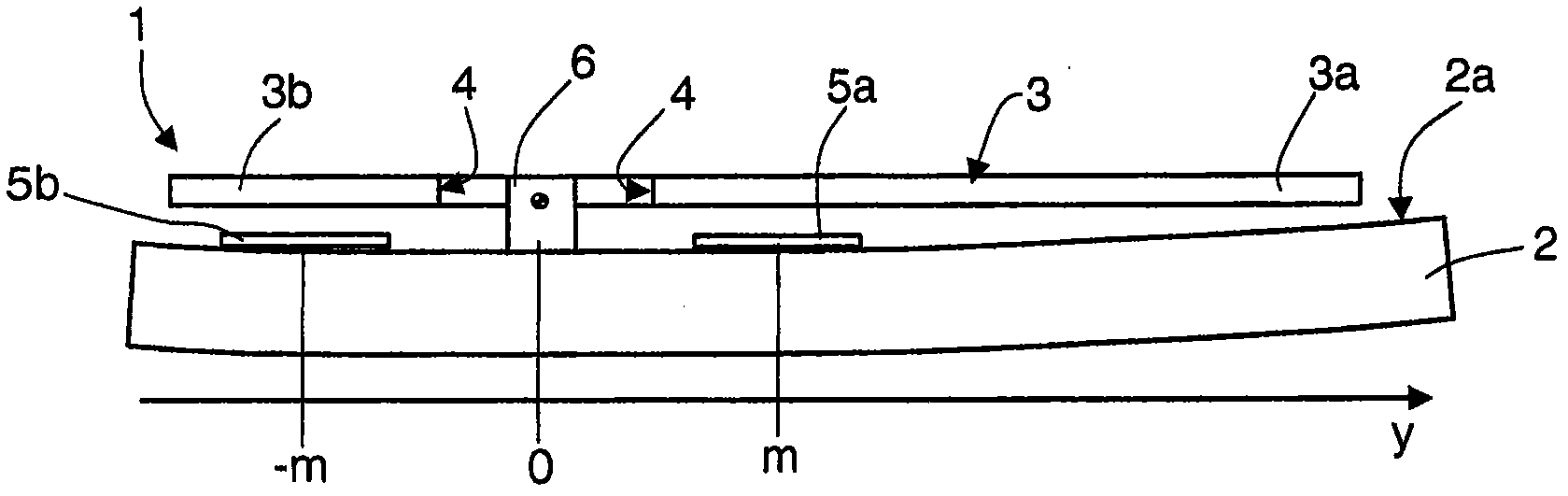

[0034] As will be detailed below, one aspect of the present invention contemplates a suitable modification of the structure of the mechanical coupling (by anchoring or support) of the sensing mass to the substrate of the MEMS structure such that: Due to the induced deformation of the substrate, the sensing mass will experience a displacement substantially in line with the displacement experienced by the fixed electrodes, thus the change in the average gap between the sensing mass and the fixed electrodes (and the associated change in capacitance value) Doesn't happen (or very little). In this way, it is possible to eliminate (or significantly reduce) any thermal drift of the sensor and associated measurement errors, even in the presence of substrate deformation. In particular, the sensing mass is coupled to the substrate by constraining points located at positions corresponding to the fixed electrodes in such a way that the displacement (in the orthogonal direction z) at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com