Anti-high voltage electric vortex shift sensor

A displacement sensor, high-voltage technology, applied in the field of non-electrical measurement, can solve the problems of cumbersome initial calibration of the sensor, increase the probe volume, small linear range, etc., achieve small resistance, strong anti-interference ability, and expand the linear range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

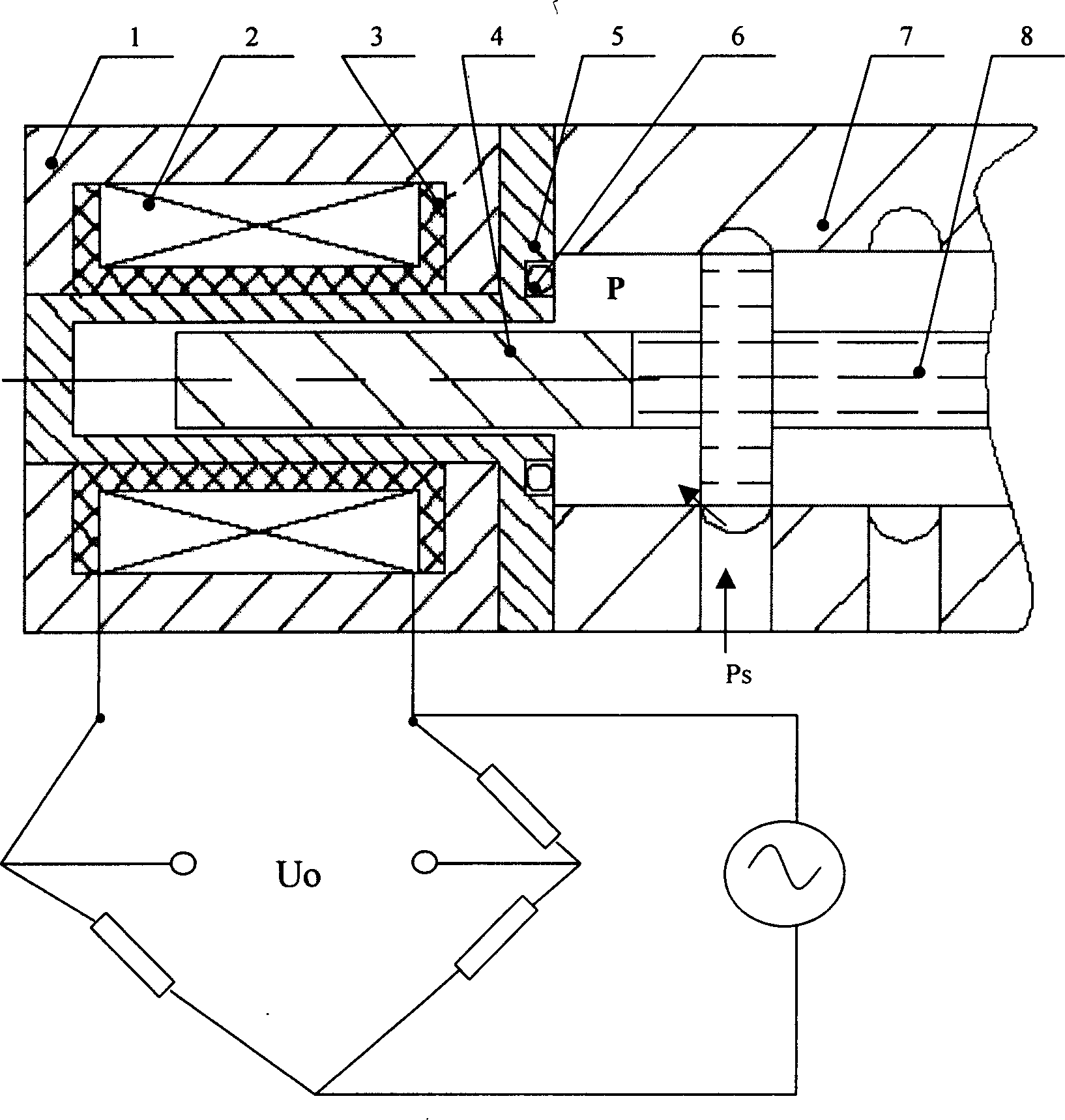

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

[0016] As shown in the drawings, the present invention comprises a shell 1, a frame 3 wound with an induction coil 2, and a short-circuit ring 4 installed in the frame 3. An inner shell 5 is installed between the short-circuit ring 4 and the frame 3; the inner shell 5 is made of high-voltage resistant non-magnetic material such as non-magnetic stainless steel; the outer shell 1 is made of soft magnetic material such as electrical pure iron; the induction coil 2. The high-strength enamelled copper wire is used for flat winding; the short-circuit ring 4 is made of conductive materials such as copper; the shell 1 can be spliced in pieces. The short-circuit ring 4 can be connected with the spool 8 by threads or the like.

[0017] The pressure fluid Ps passes through the valve port and enters the P cavity, and the pressure of the P cavity can reach 32MPa; the inner shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com