Adhesive composition for halogen-free covering film and covering film coated by the same

A cover film and adhesive technology, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive type, etc., can solve the degradation of heat resistance and adhesive strength of cover film, The cover film does not meet the required performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

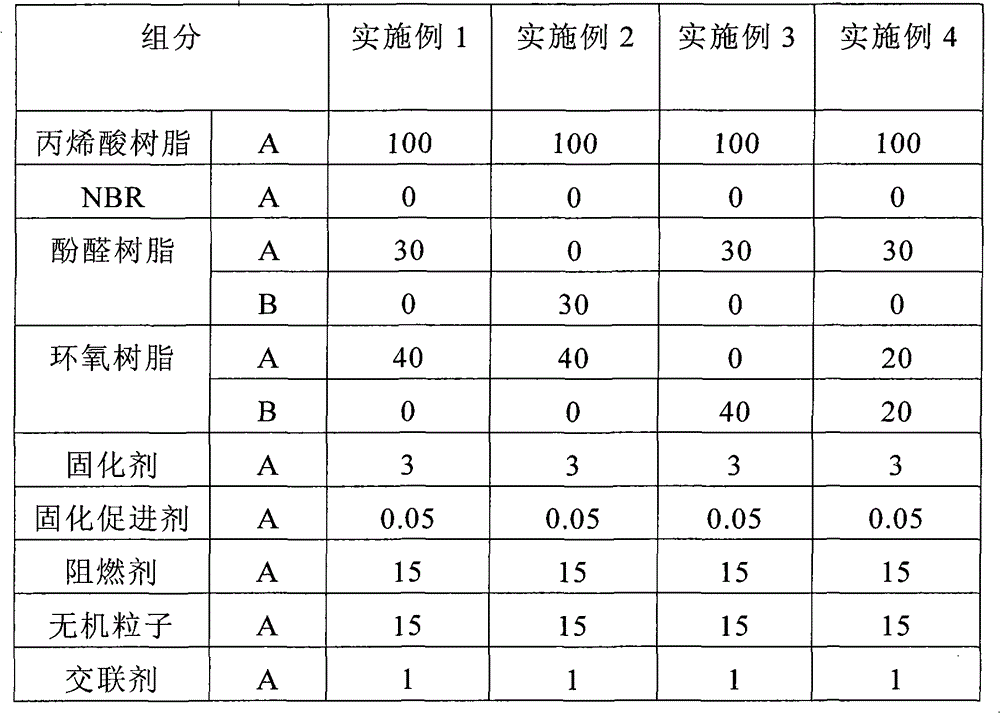

[0051] The components shown in Table 1 below and methyl ethyl ketone with a solid content of 30% were added and uniformly mixed with a homogenizer. Next, the mixed composition was applied on a polyimide film having a thickness of 12.5 μm in such a manner that the thickness after drying was 25 μm, followed by drying and thermal curing in an oven at 50° C. for 10 minutes, and at 160° C. °C Dry in an oven and heat cure for 3 minutes. Finally, a release paper was laminated thereon to prepare a cover film.

Embodiment 2~4

[0053] Cover films were prepared in the same manner as in Example 1 except that the components of the adhesive were added as shown in Examples 2 to 4 of Table 1 below.

[0054] [Table 1]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap