Compact strand die-drawing rolling production process and production equipment thereof

A technology of production process and production equipment, which is applied in the field of production equipment for the production of compacted strands, can solve the problems of complex tooling design, large deformation and heat generation of steel wires, rough surface of compacted strand steel wire ropes, etc. Shares, the effect of increasing the compression factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

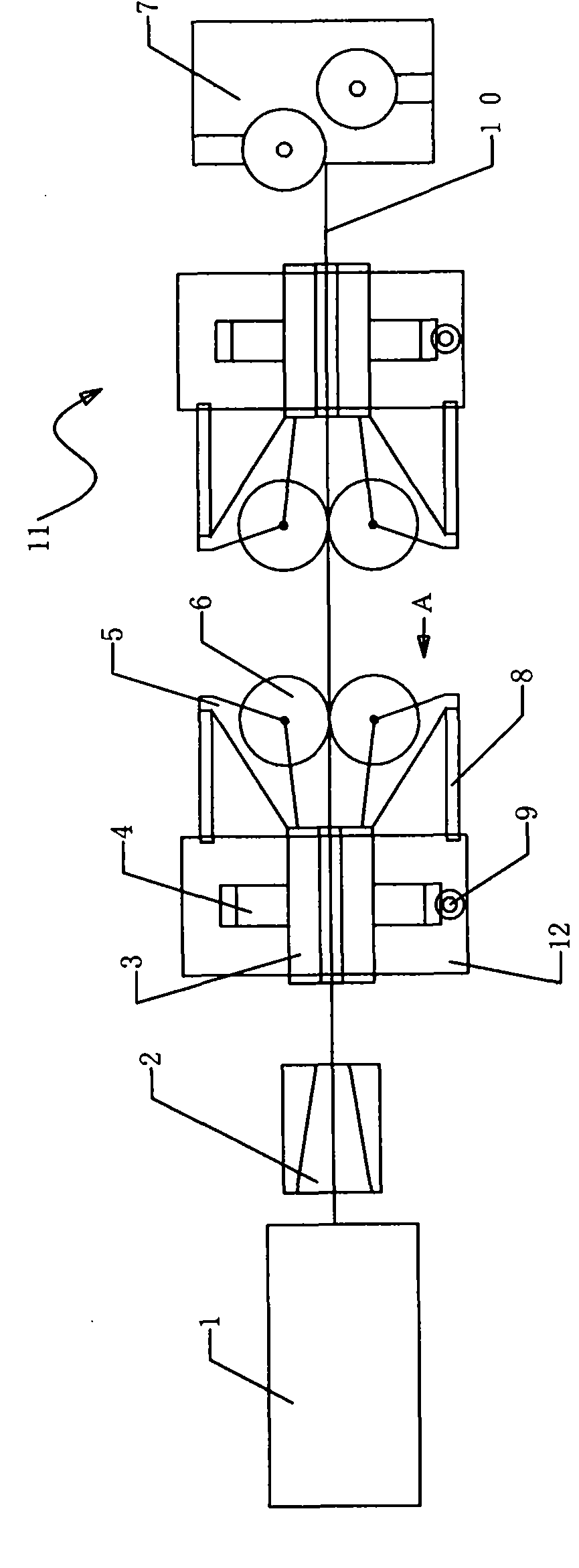

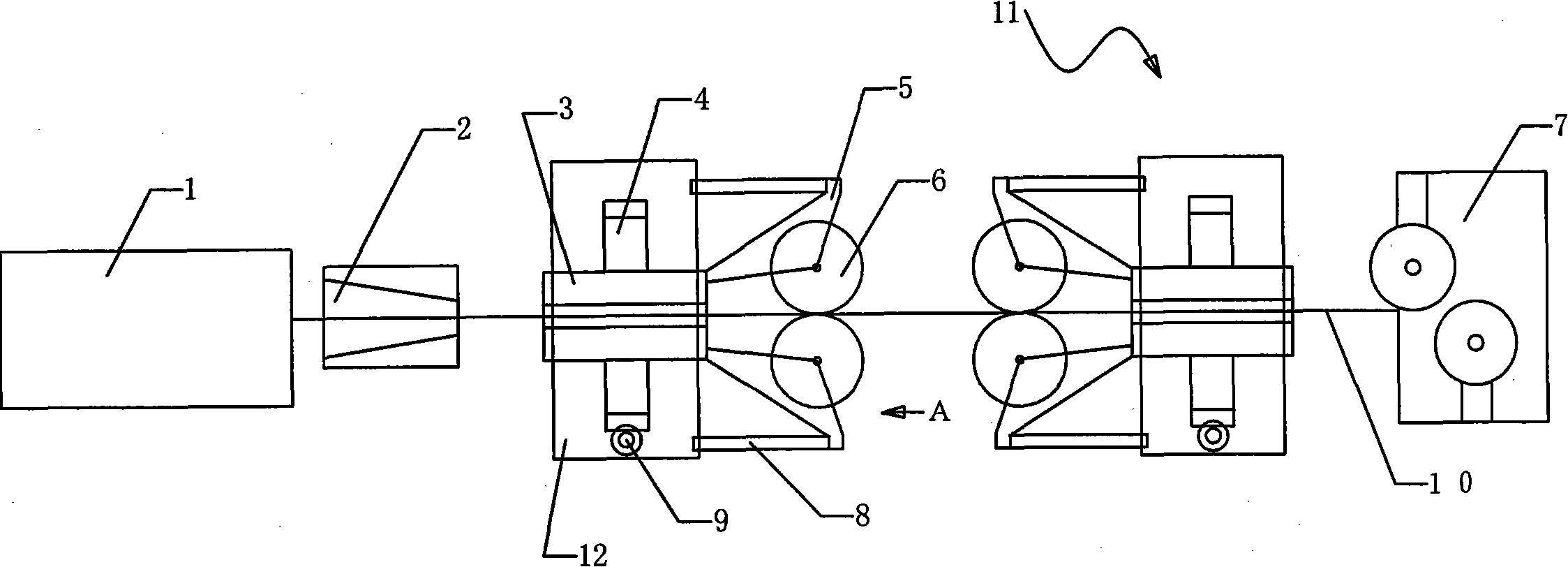

[0020] In the embodiment of the production process of the compacted strand die-drawing and rolling of the present invention, when producing the compacted strand steel wire rope, the raw steel wire to be processed is twisted, molded and compacted, rolled, and then deformed to relieve stress to obtain the compacted strand. Wherein, the production process specifically includes the following process steps:

[0021] Step 1. Twisting strands: Twist the raw steel wires to be processed into one strand through a twisting machine;

[0022] Step 2. Die drawing and compaction: pass the twisted steel wire strands through the wire drawing die, and the wire drawing die squeezes the steel wire strands to deform them and reach the specified compression coefficient;

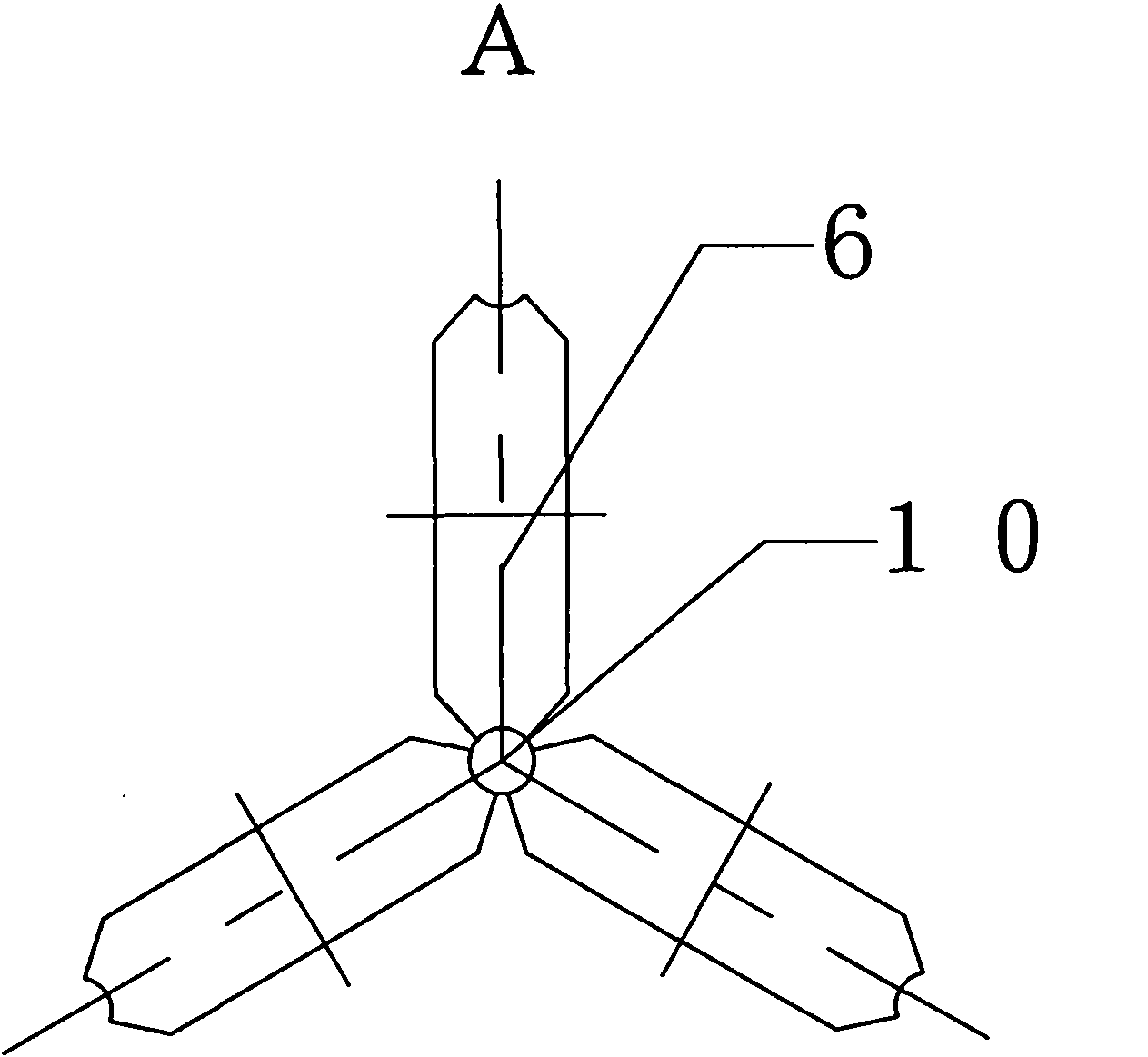

[0023] Step 3. Rolling: Send the wire-drawn steel wire strands into a rolling device with three pressure rollers evenly arranged in the circumferential direction for rolling. In this step, the wire-drawn steel wire strands pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com