Pulp board machine for producing water absorbent resin-containing pulp boards

A technology of water-absorbent resin and pulp board machine, which is applied in the direction of paper machine, fiberboard, paper machine wet end, etc. It can solve the problems of paper breaking and water-absorbent resin hindering the hanging of the net, etc., and achieves the effect of low cost and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

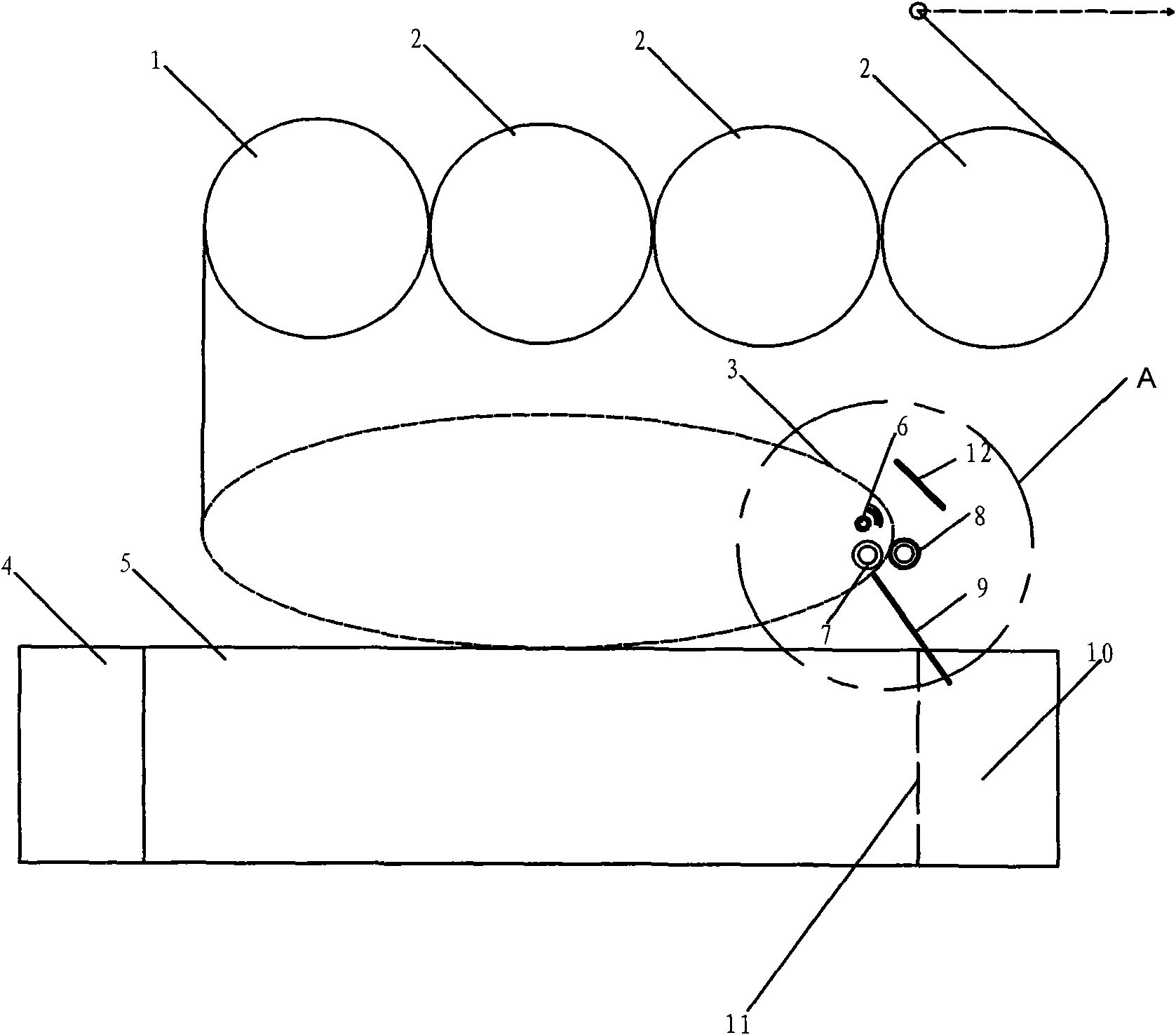

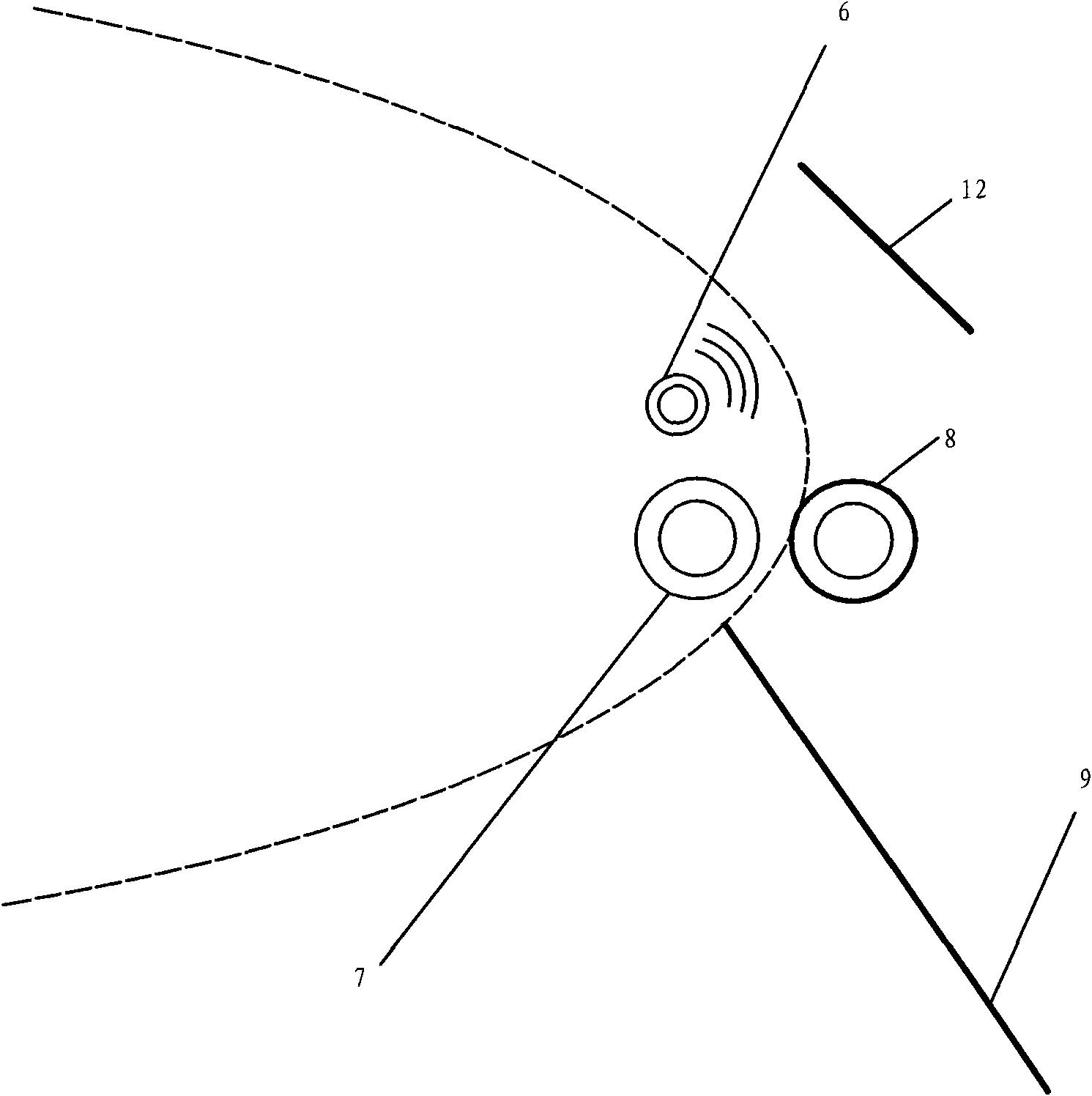

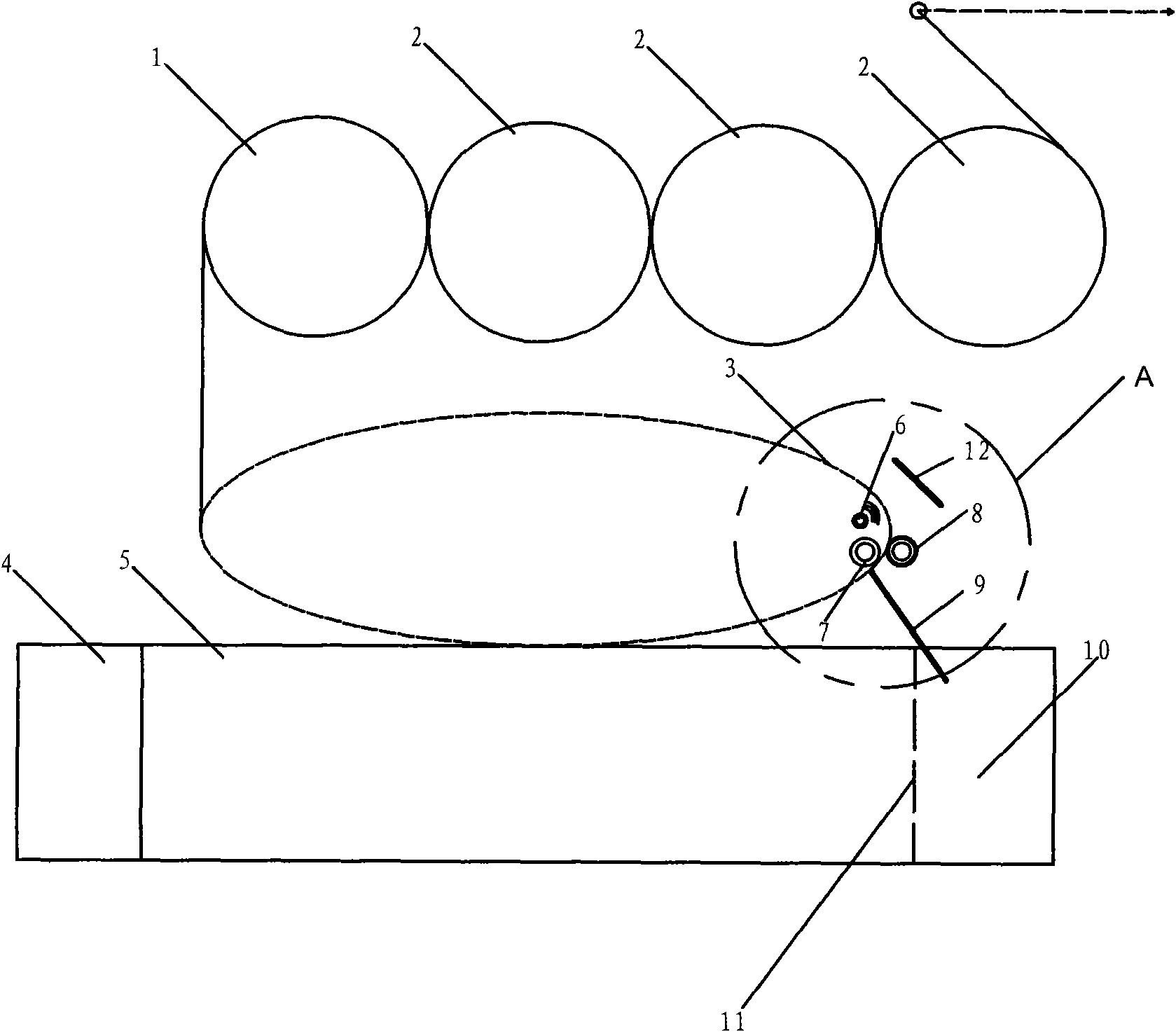

[0022] The present invention notices that when producing the pulp board containing water-absorbing resin, the paper is broken without hanging the net, because the excessively large gel-like water-absorbing resin particles cover the mesh in sheets after absorbing water, and the gap between the pulp fiber and the mesh wheel is cut off. direct contact. The gel-like water-absorbent resin particles that block the mesh are a form of covering rather than plugging. As long as this covering of the gel-like water-absorbing resin particles is sporadically dispersed, the pulp fibers will not be covered by the gel-like water-absorbing resin particles. A large area is separated from the screen wheel, the phenomenon of paper break due to hanging the net can be overcome, and the production of pulp board containing water-absorbent resin can be realized.

[0023] Specific embodiments of the present invention are illustrated in more detail below with reference to the accompanying drawings:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com