Gardening trimmer

A pruning machine and gardening technology, applied in gardening, gardening tools/equipment, applications, etc., can solve problems such as unpleasant vibration and noise, quality balance deterioration, etc., to suppress vibration and noise, prevent mass balance deterioration, and improve usability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] First, main features of the embodiments to be described next are listed.

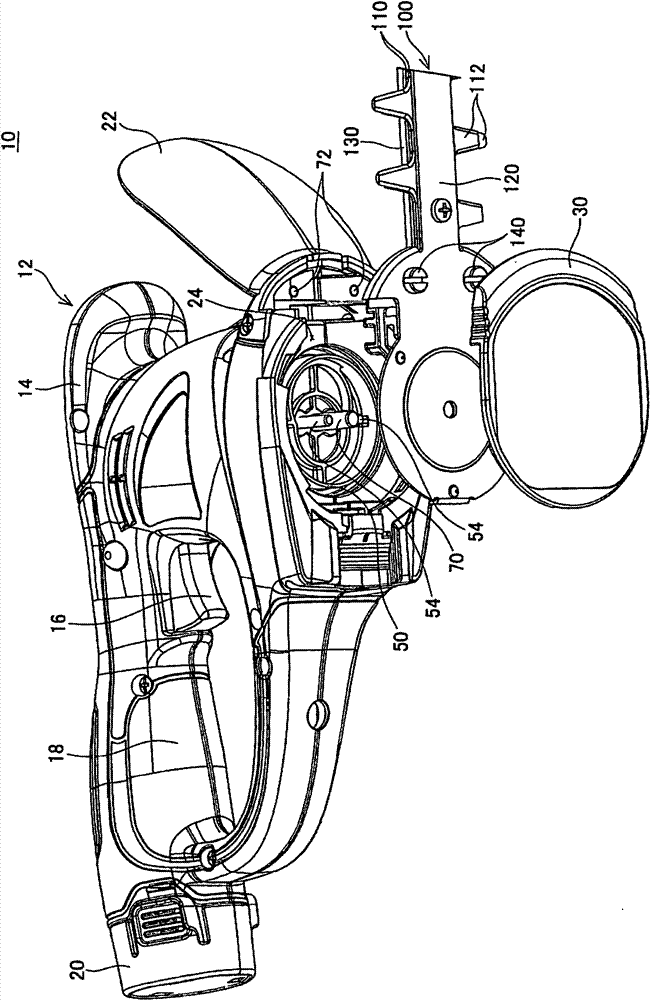

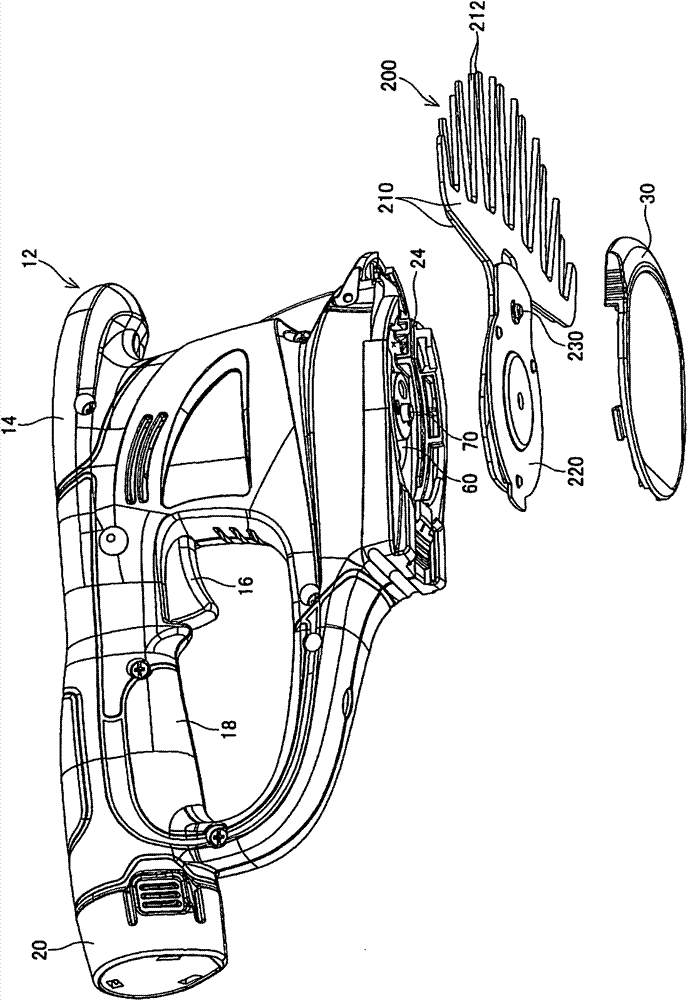

[0037] (Feature 1) The garden trimmer includes two types of blade assemblies. The first blade unit is a hedge blade unit mainly used for trimming hedges, and the second blade unit is a lawn blade unit mainly used for lawn trimming. However, the hedge blade unit can be used not only for trimming hedges but also for trimming other trees. Similarly, the lawn blade assembly can not only be used for mowing the lawn, but also can be used for mowing other flowers and plants.

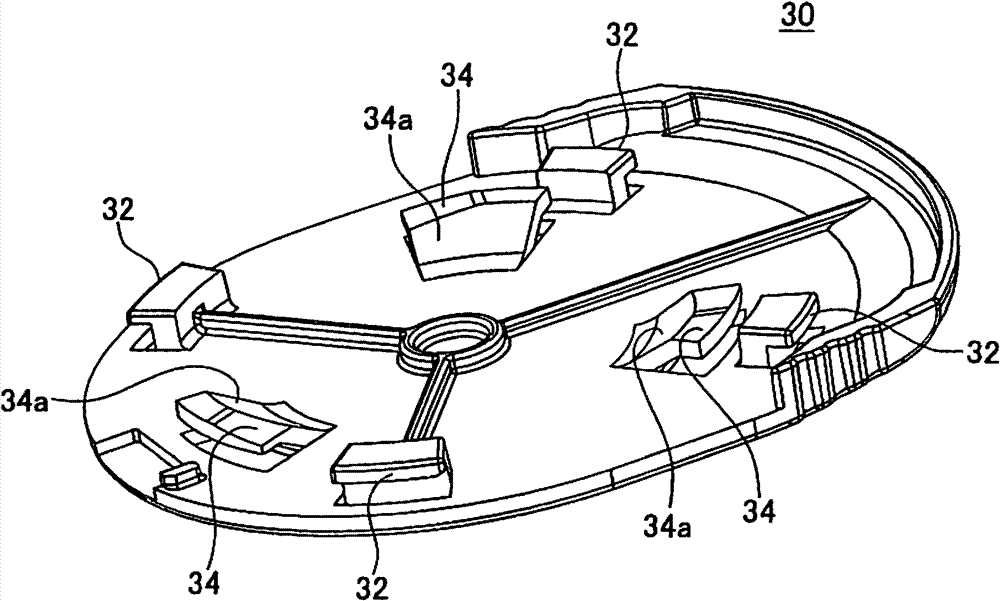

[0038] (Feature 2) Each blade unit has a pair of shearing blades. The pair of shearing blades are supported slidably or swingably, respectively. An engaging hole for engaging with any one of the cam members is provided at a base end portion of each shearing blade. The engaging hole is oblong, and its long diameter direction is perpendicular to the sliding or swinging direction of the shearing blade. Accordingly, each shearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com