Weaving strip producing method and equipment thereof

A production method and technology of production equipment, applied in the field of braided strip production and its equipment, can solve problems such as damage to the surface of the braided strip, inconsistent color patterns, affecting appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

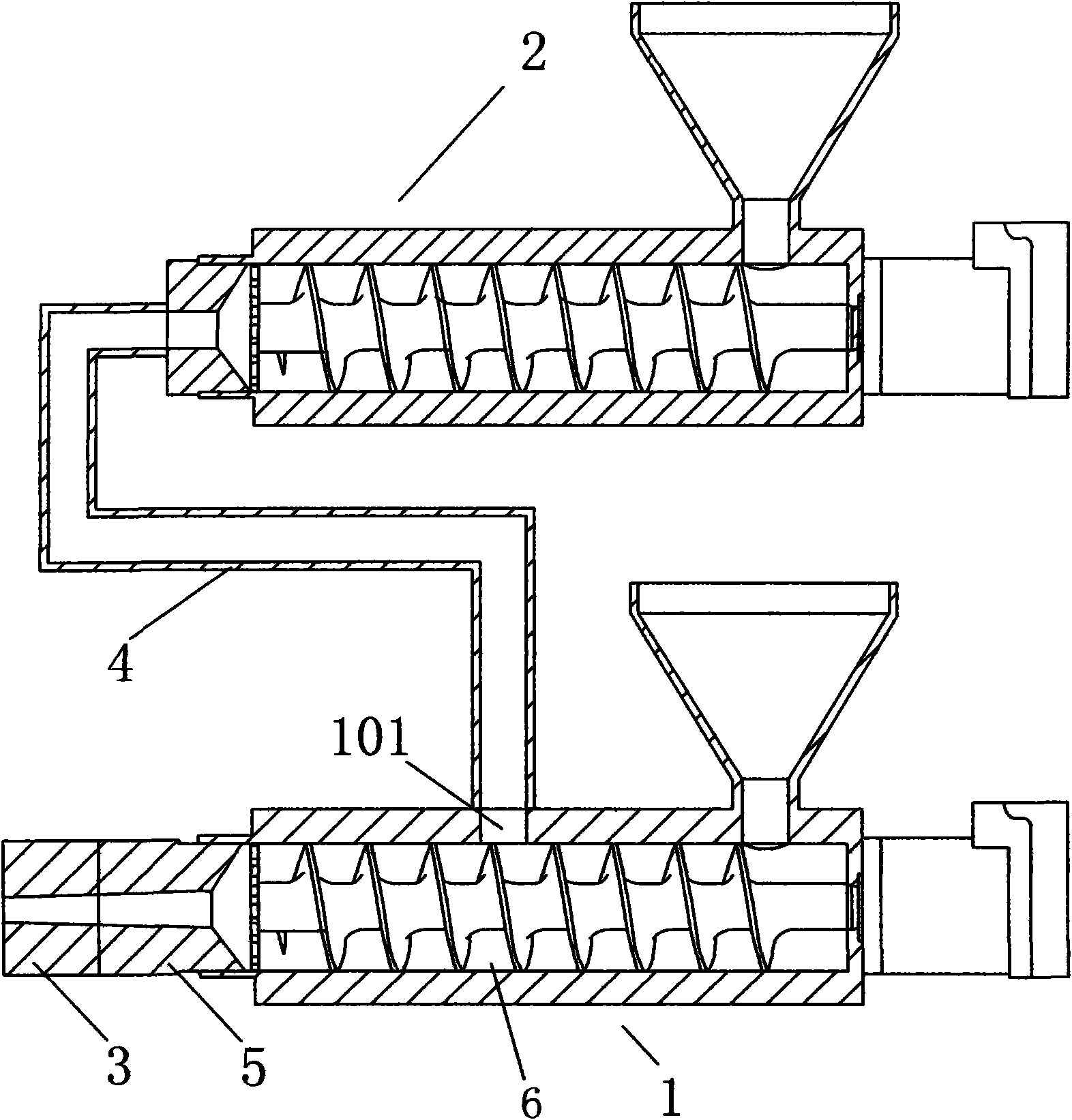

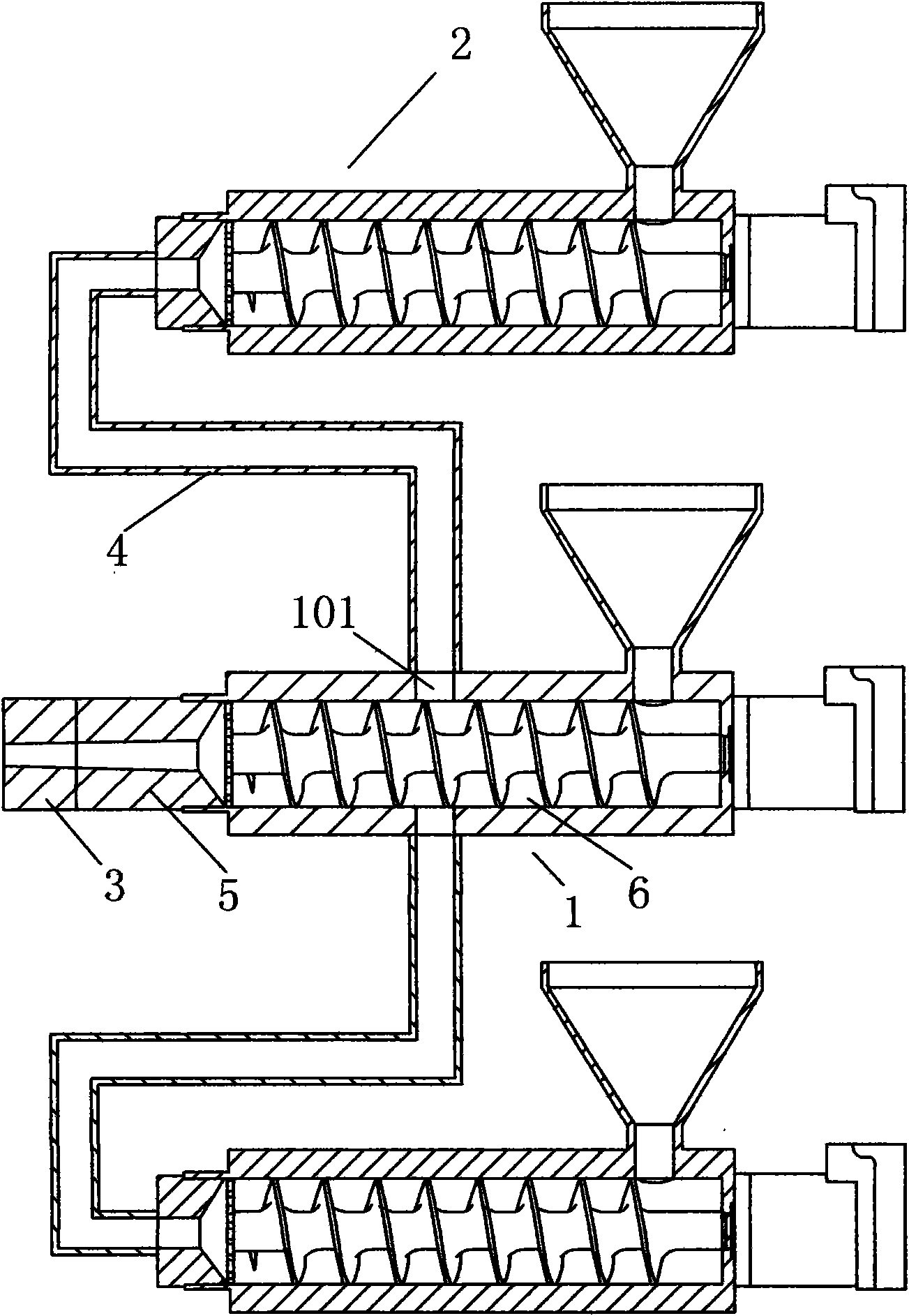

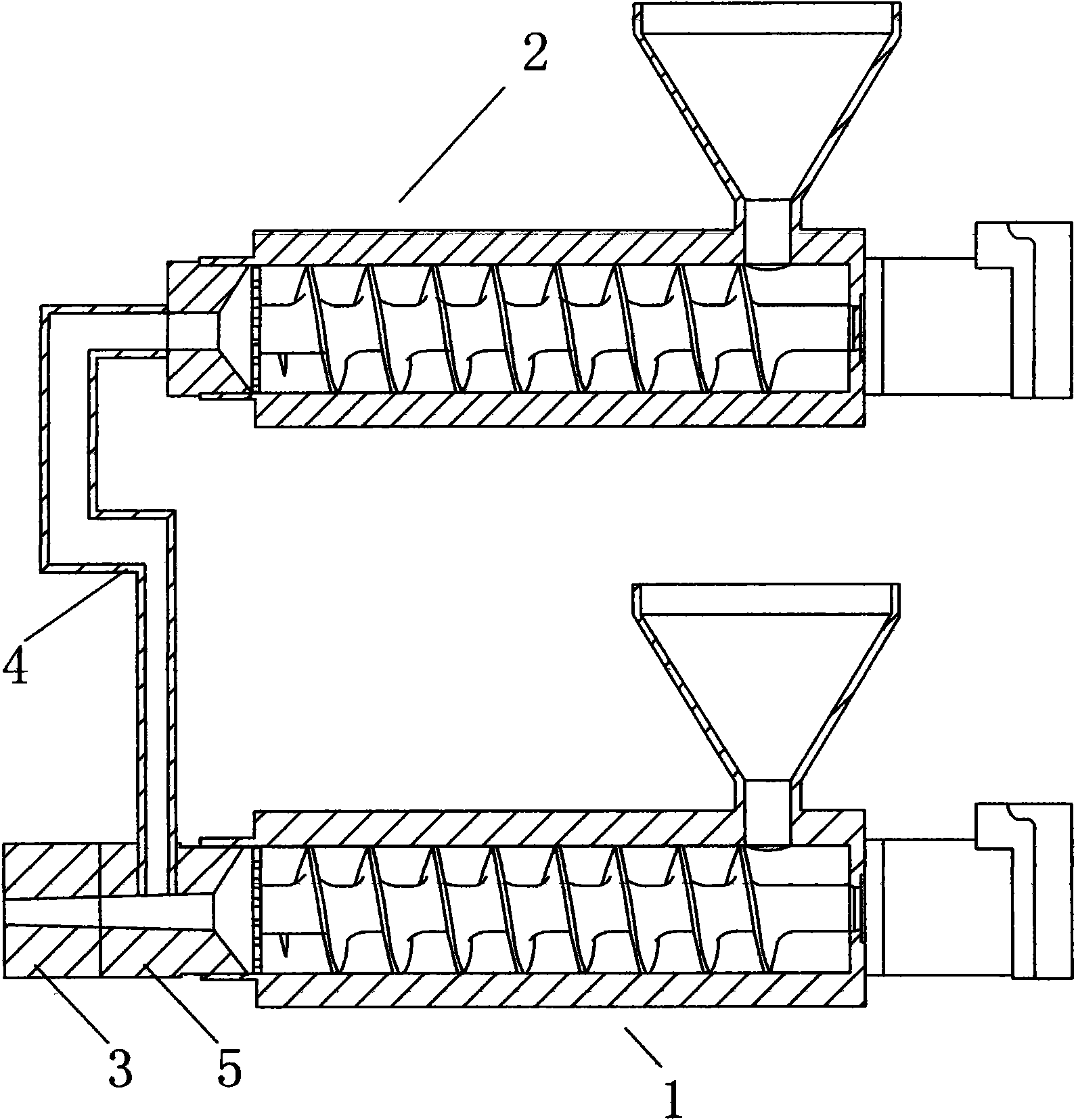

[0020] The present invention will be specifically and further described below in conjunction with the accompanying drawings.

[0021] As shown in the figure, in the production method of braided strips, the production materials of braided strips are put into the extruder, heated and dissolved into a liquid state and extruded from the mold 3, and the production materials are composed of two or more kinds, wherein Material A is heated to a dissolved liquid state, material B is heated to a surface dissolved and the core is still in an undissolved state, and material B and material A are mixed and extruded.

[0022] The material A is put into the first extruder 1 for stirring and heating, and the material B is put into the second extruder 2 and heated until the surface is dissolved and the core is still in an undissolved state, and the second extruder 2 will be half-dissolved. The material B in the state is fed into the mixing section of the first extruder 1, and is stirred and mix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap