Fed paper cutting position adjustment and compensation device of packing machine

A compensation device and machine feeding technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of waste products, low tracking accuracy, and slow system response speed, achieving fast compensation speed, high product qualification rate, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

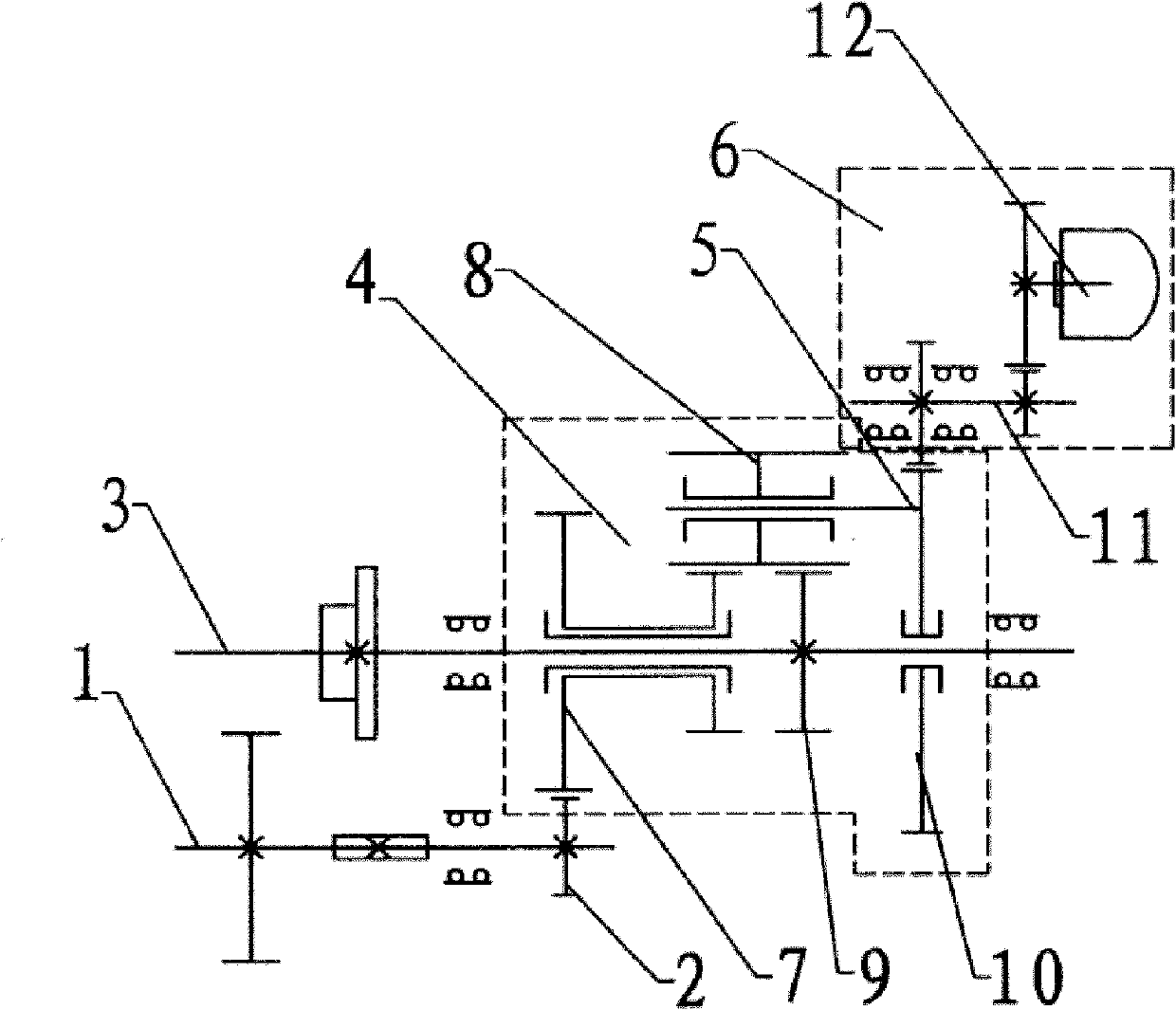

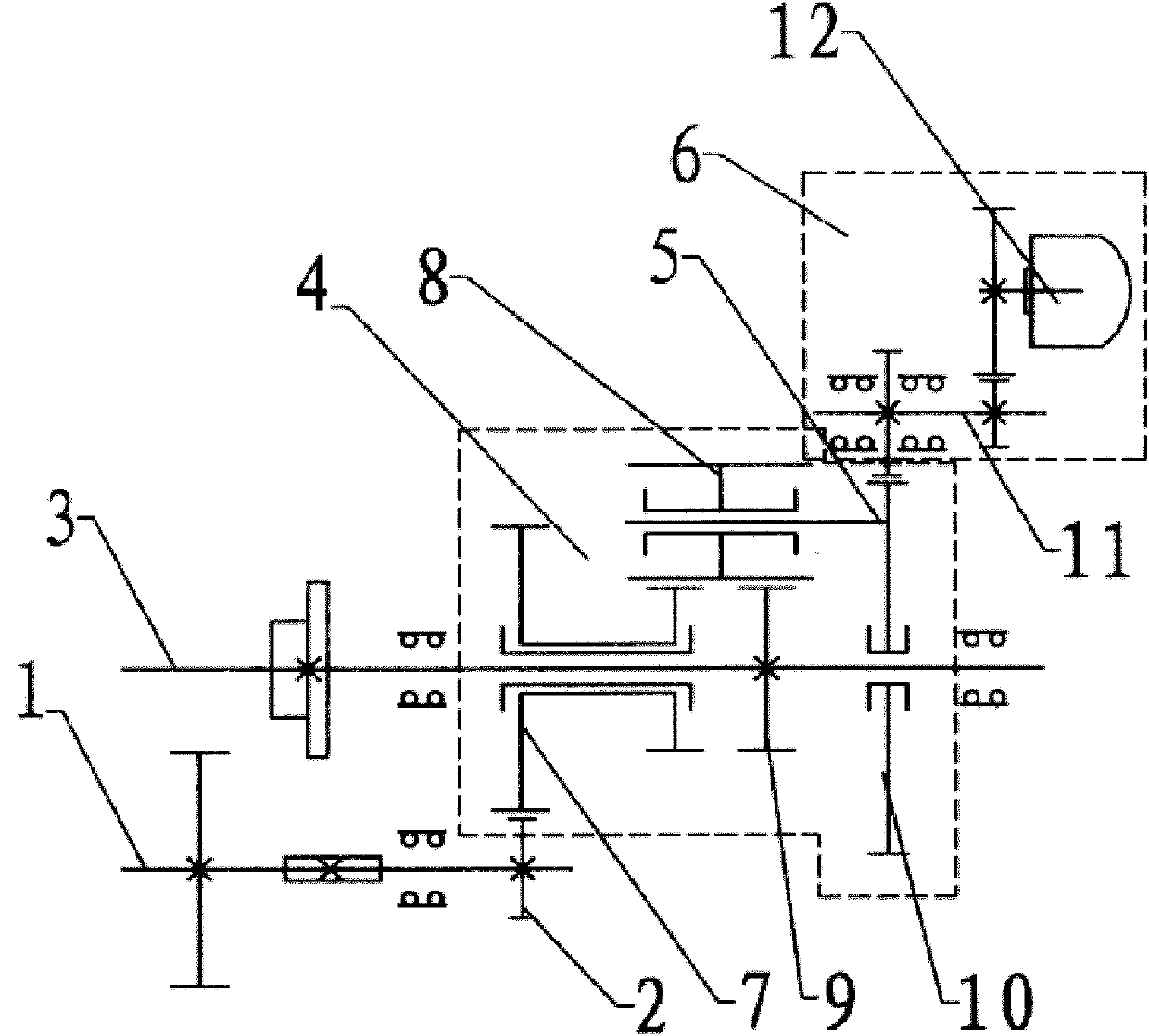

[0012] Such as figure 1 As shown, the cutting position adjustment and compensation device of the packaging machine includes a power input shaft 1, an input gear 2 fixedly connected with the power input shaft 1, and a power output shaft 3. The power output shaft 3 is provided with a planetary gear mechanism 4, and the planetary gear mechanism 4 comprises sun gear 7, planetary gear 8, sun gear 9 and rotating arm 5. The central gear 7 and the rotating arm 5 are loosely sleeved on the power output shaft 3, the sun gear 9 is fixedly connected with the power output shaft 3, the input gear 2 is meshed with the central gear 7, and the central gear 7 and the sun gear 9 are meshed with the planetary gear 8 at the same time. The rotating arm 5 is provided with a rotating arm gear 10 fixedly connected with the rotating arm 5. The rotating arm gear 10 meshes with the gear pair 11 on the speed compensation and locking mechanism 6. The speed compensation and locking mechanism 6 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com