Electric wheel type pile driver

A pile driver and wheeled technology, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems that migrant workers cannot afford

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

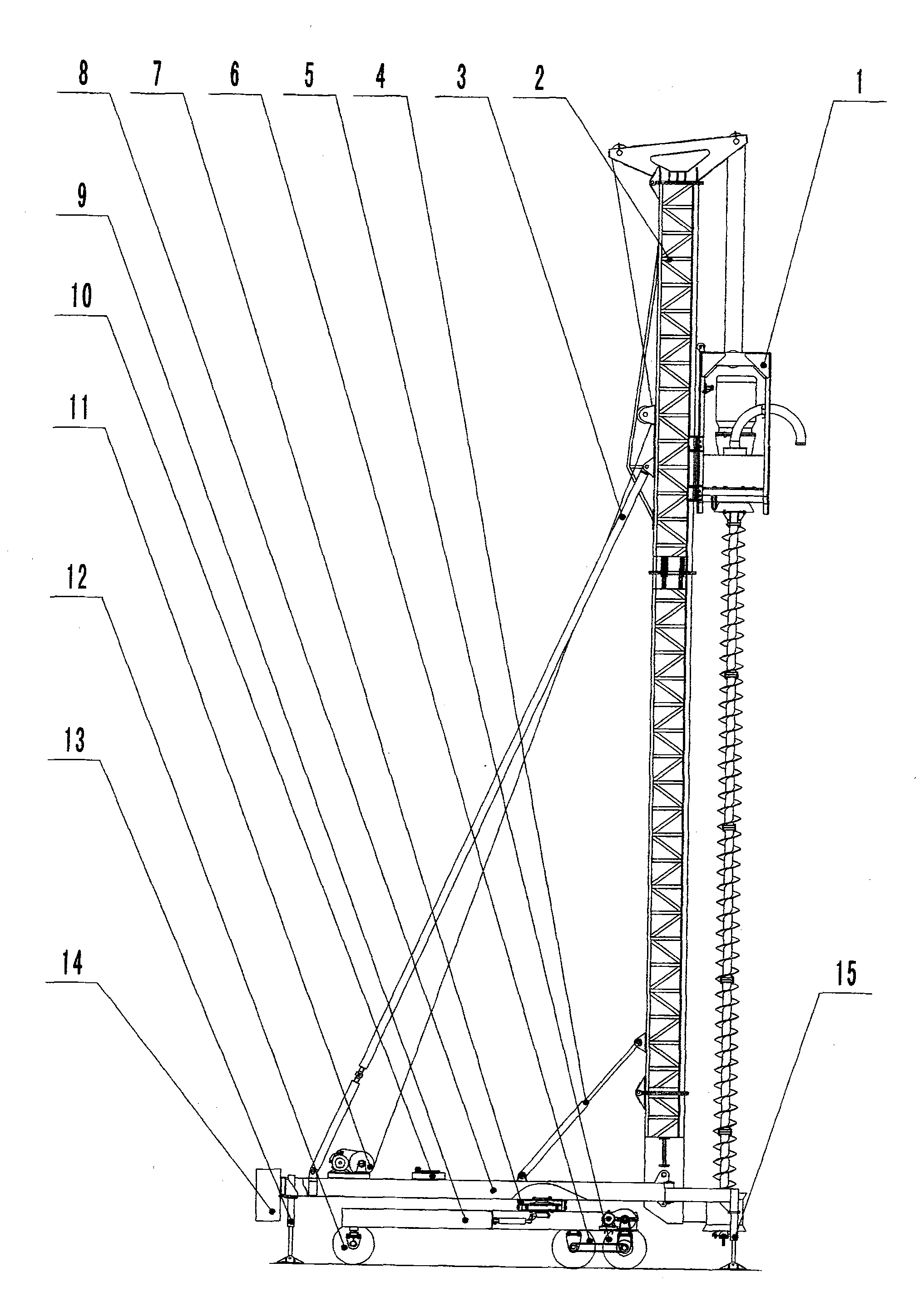

[0019] First, in conjunction with the accompanying drawings, the key structure and working principle of the present invention are introduced.

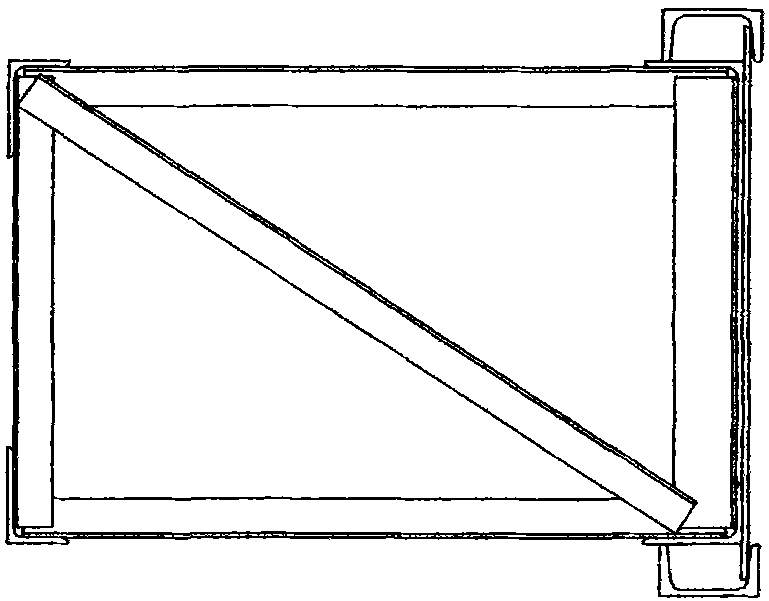

[0020] figure 2 . The cross-sectional structure of the truss column of the present invention. The unique feature is that one of the four sides of the column is a steel plate, and the other three sides are angle steel. Behind the steel plate, there are diagonal braces along the diagonal direction of the section. It is advisable to choose unequal angle steel for angle steel and place the long side on the outer surface with the largest force. Two channel steels are welded on both sides of the steel plate as column slideways. Compared with the column with steel plate welding on all four sides on the existing various pile machines, the column with diagonal brace behind the steel plate on one side can reduce the weight by half and have similar bending and torsional strength.

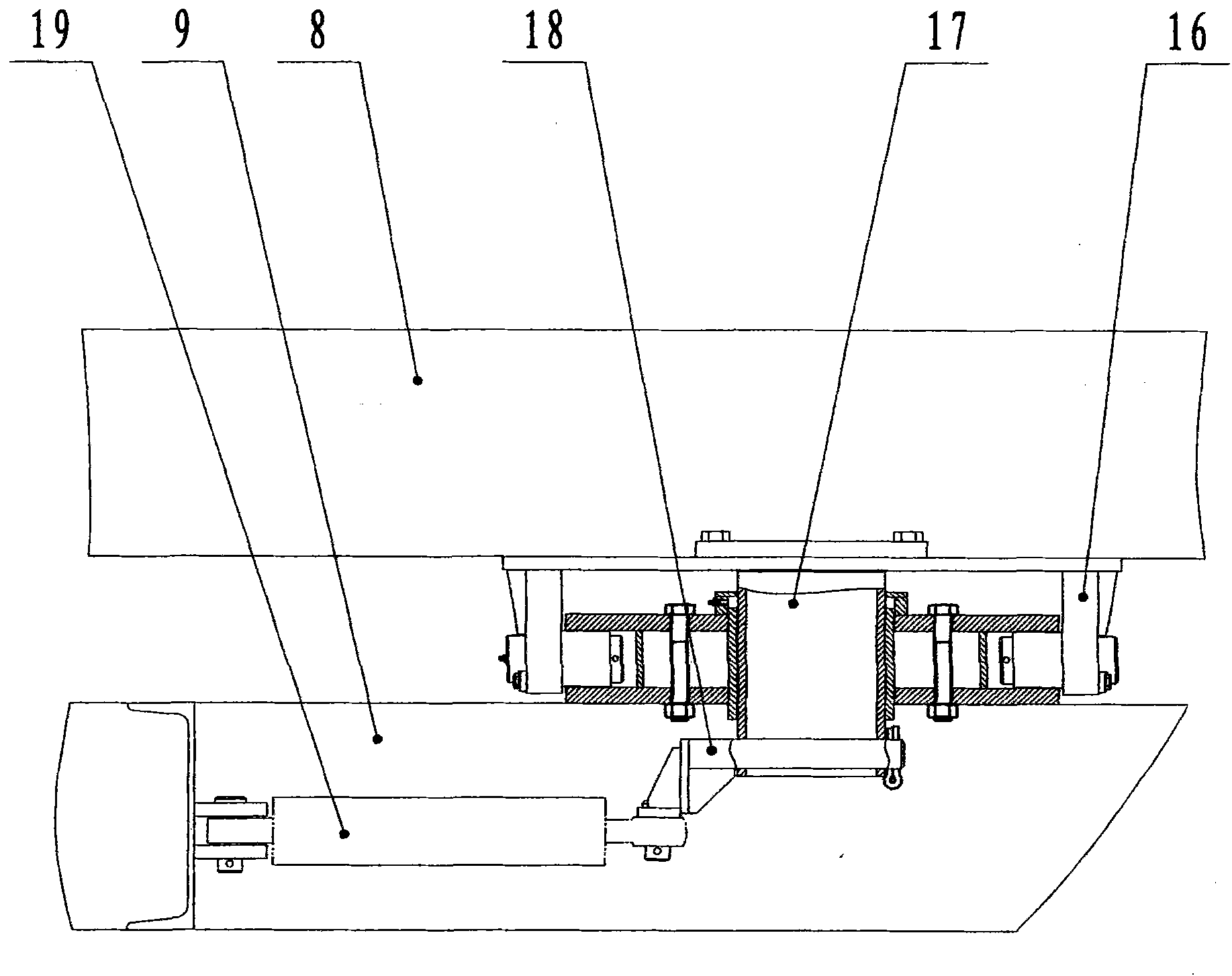

[0021] image 3 .Roller type slewing bearing structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com