Rotating rotary-fixing type assembly fixing device

A technology of fixing devices and components, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long operation time, large volume, difficult placement and transportation, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

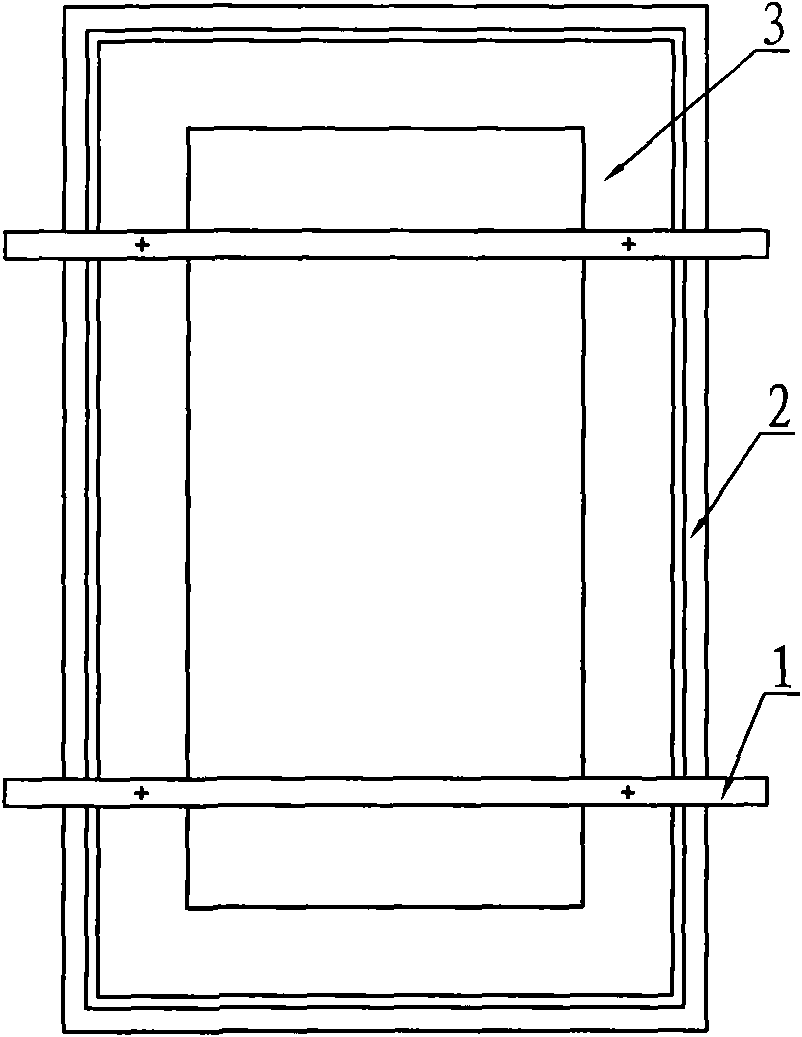

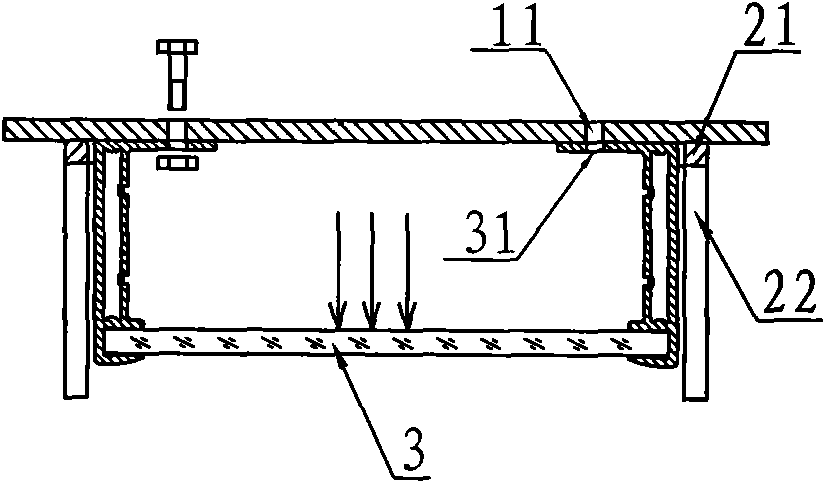

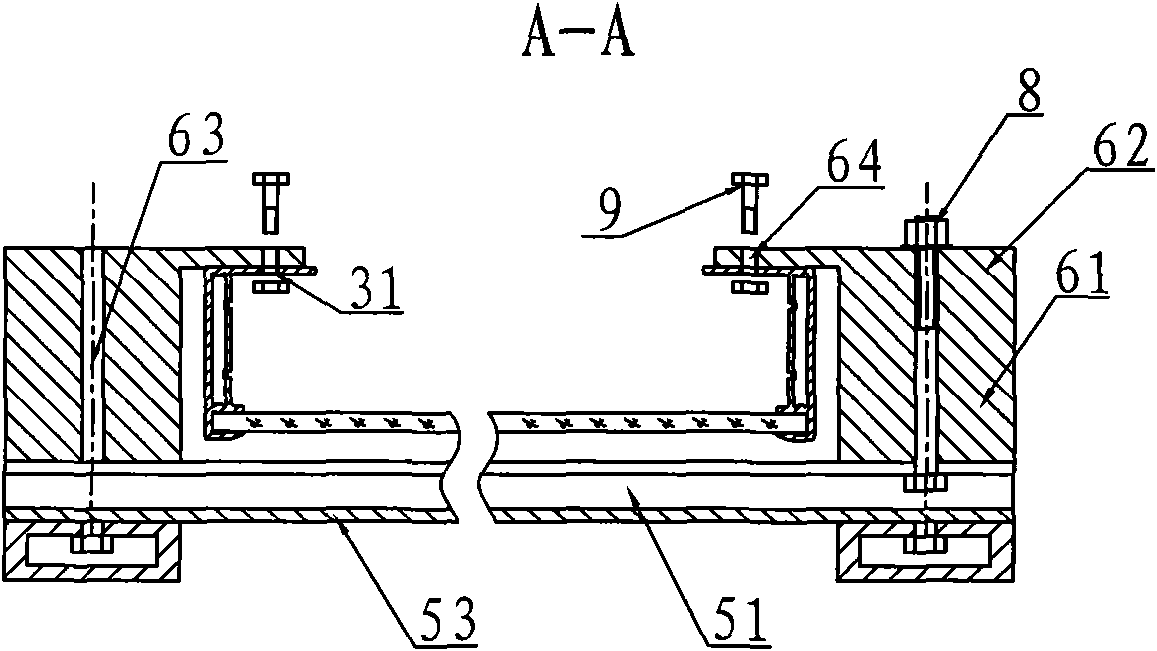

[0020] Embodiment 1: The rotating and screwing type component fixing device used for the static pressure test of the solar cell component, such as Figure 3-7 As shown, it includes a solar cell module 3 to be tested, two longitudinal bars 4, two transverse bars 5 and four rotating hangers 6, and the two longitudinal bars 4 are fixed on the frame in parallel, equal height, and horizontally, and the two The spacing between the longitudinal bars 4 is greater than the width of the solar cell module 3 to be tested, two transverse bars 5 are installed on the two longitudinal bars 4 parallel to each other, the transverse bars 5 are perpendicular to the longitudinal bars 4, and the longitudinal bars 4 are vertically arranged There is a longitudinal adjustment groove 41, and four short bolts 7 are sleeved in the longitudinal adjustment groove 41; the horizontal bar 5 is composed of an ear seat 52 and a connecting rod 53, and the two ends of the connecting rod 53 are provided with ear se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com