Retractable lens barrel with high shock resistance

A technology of a lens barrel and a barrel member, which is applied in the field of retractable lens barrels, can solve problems such as obstructing the optical equipment of the lens barrel, and achieve the effect of improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be described in detail with reference to the accompanying drawings showing embodiments of the invention.

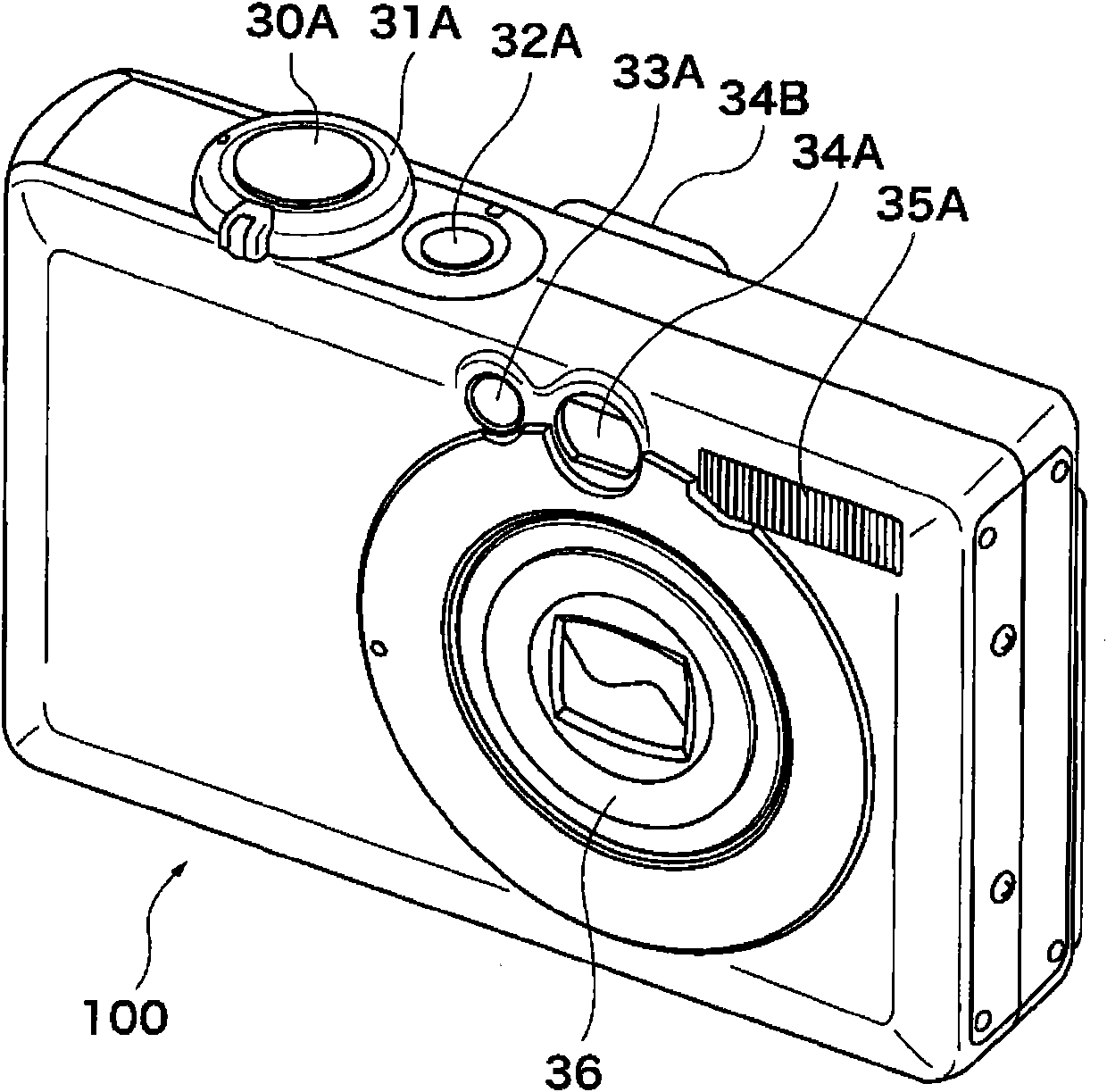

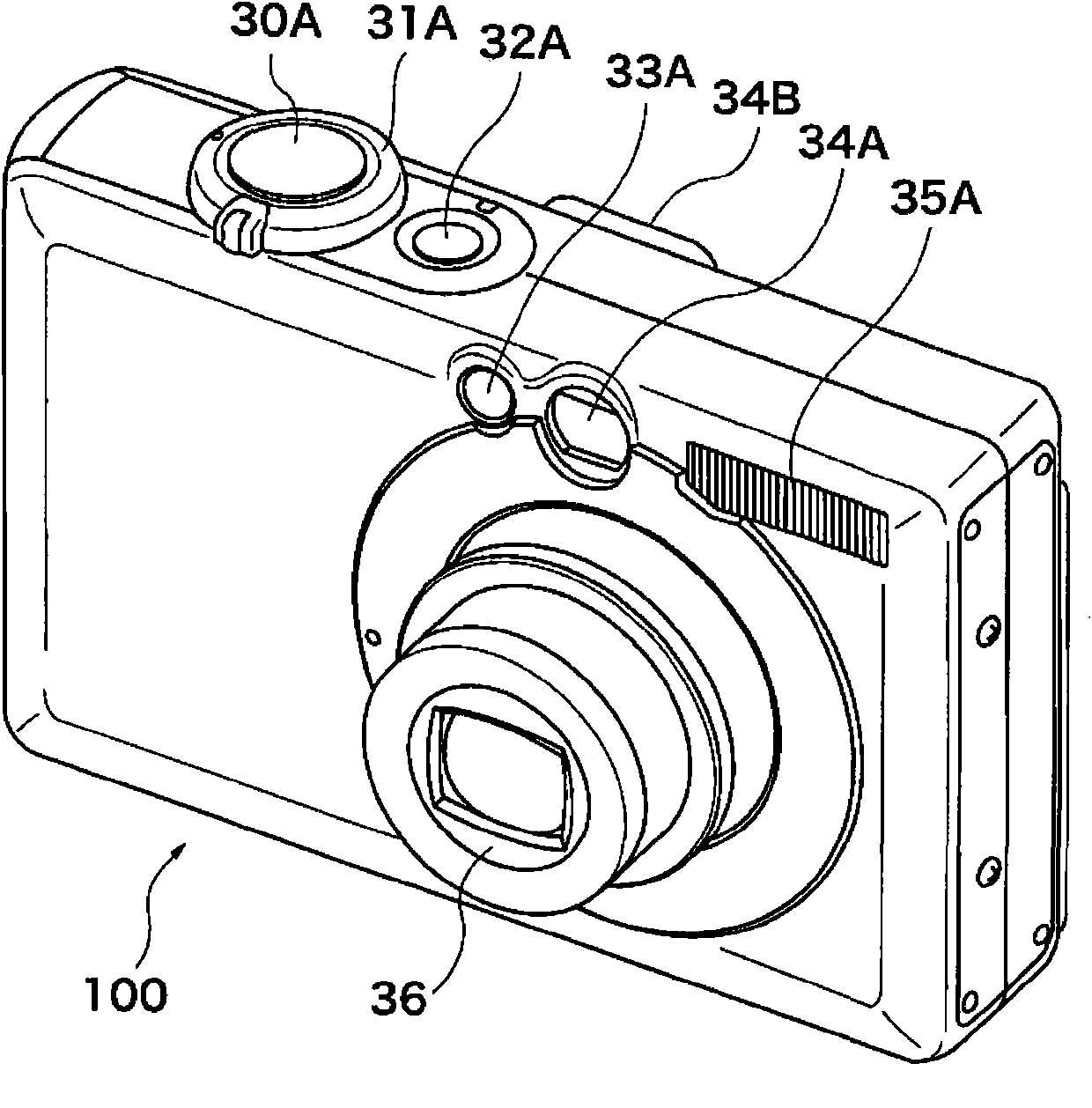

[0019] Figure 1A with Figure 1B is an external perspective view showing a digital camera having a retractable lens barrel according to an embodiment of the present invention, wherein, Figure 1A shows the retracted state of the retractable lens barrel, while Figure 1B The extended state of the retractable lens barrel is shown.

[0020] refer to Figure 1A with Figure 1B , an auxiliary light window 33A, a viewfinder window 34A, a flash window 35A, and a retractable lens barrel 36 are mounted on the front of the digital camera 100 .

[0021] During photometry and distance measurement, auxiliary light is emitted to the subject from the auxiliary light window 33A. An optical image of a subject is taken into the camera from a viewfinder window 34A, and the image of the subject can be viewed through a viewfinder eyepiece 34B provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com