Optical proximity correction method

An optical proximity correction and optical technology, applied in the field of lithography, can solve problems such as long time-consuming and affecting production efficiency, and achieve the effect of improving production efficiency and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

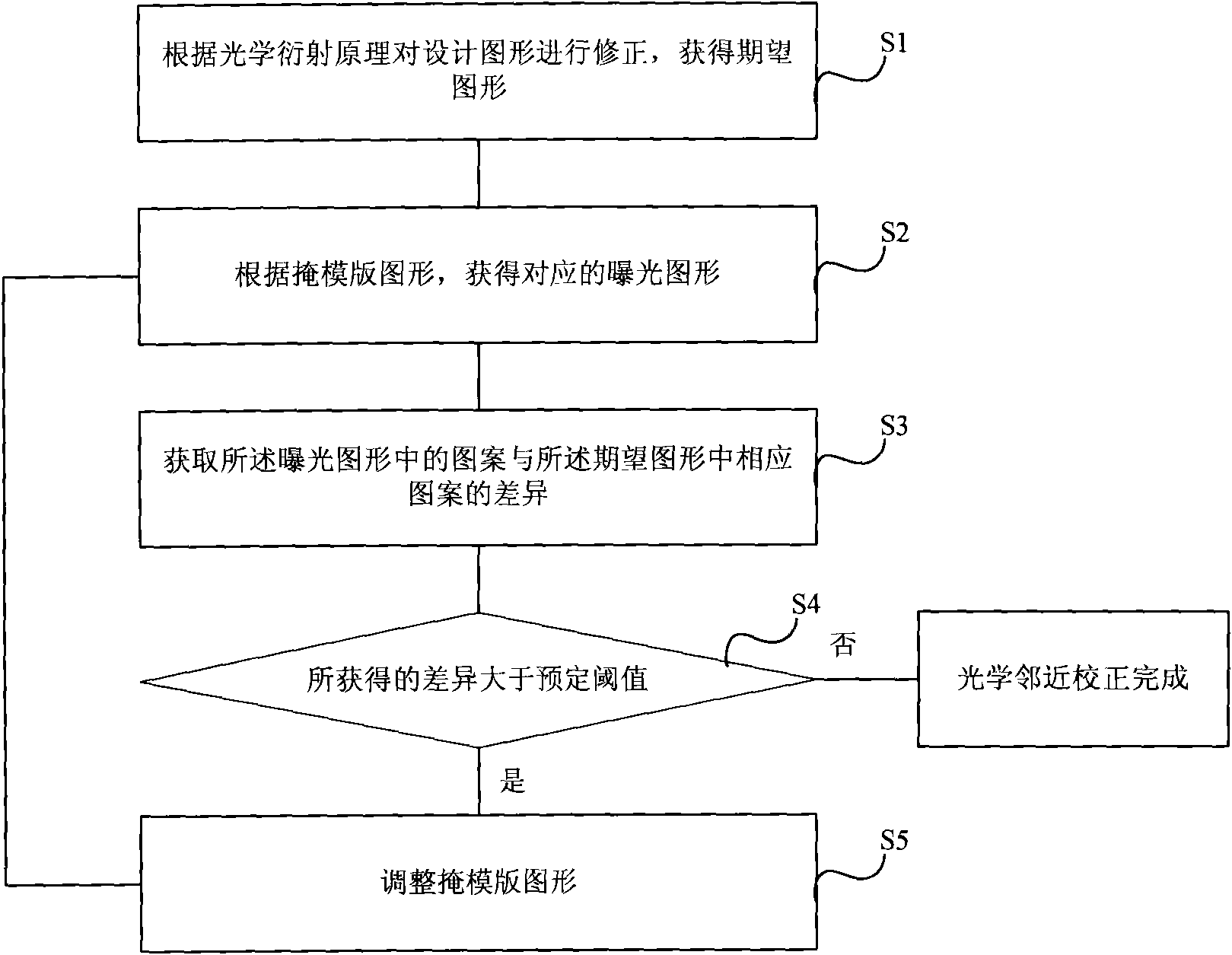

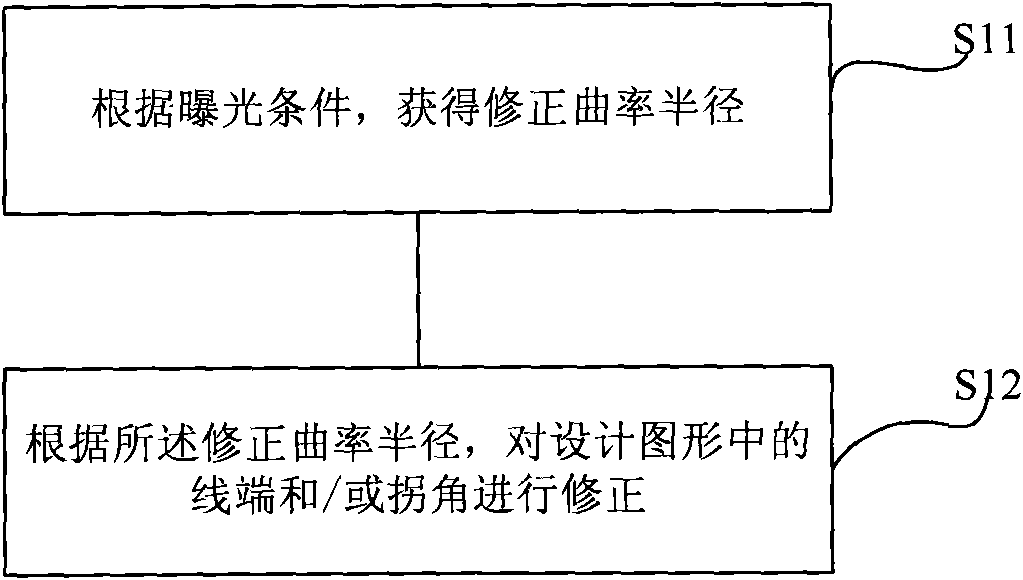

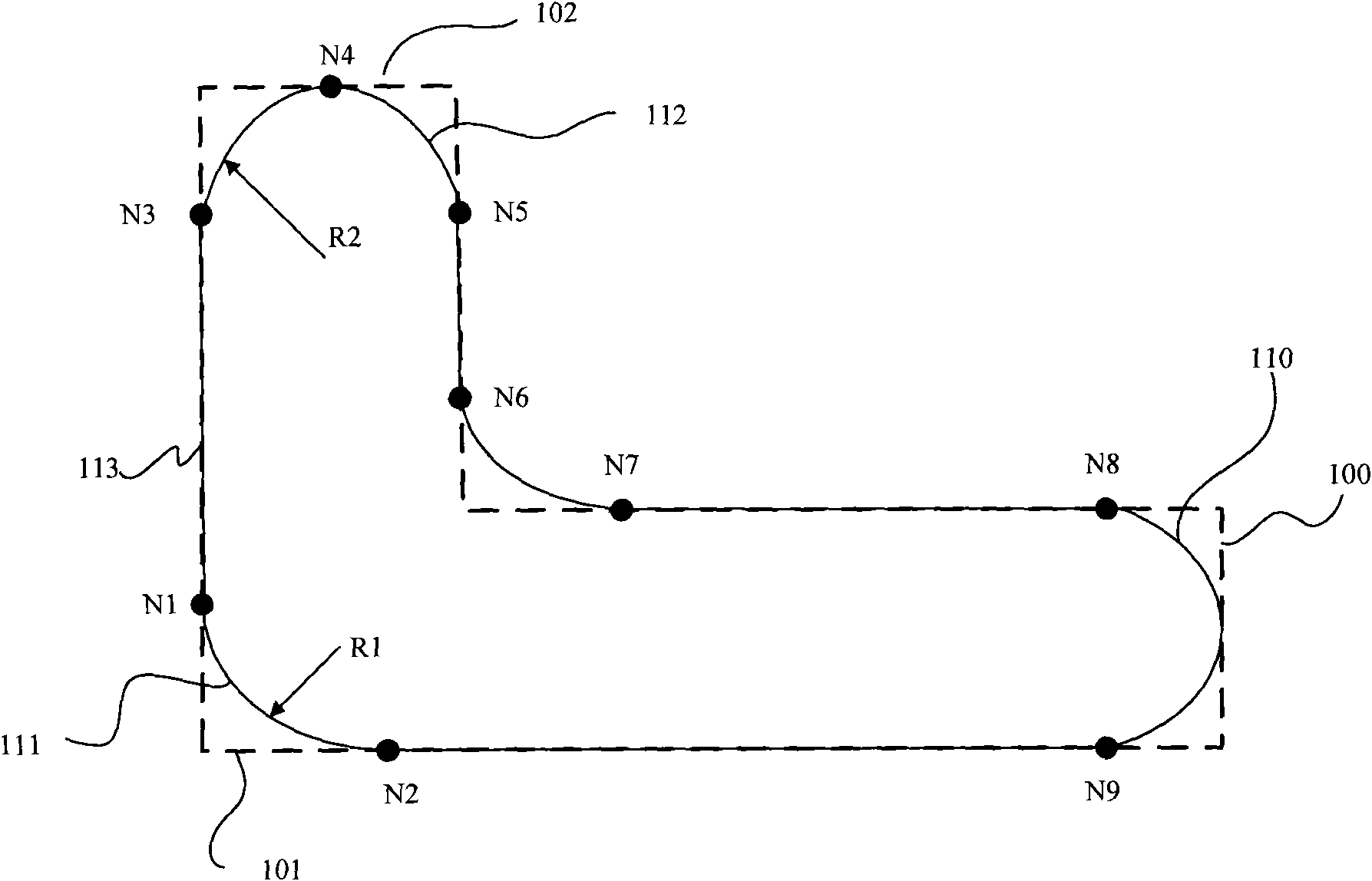

[0016] In a conventional optical proximity correction method, a better reticle pattern is obtained by repeatedly calculating the distance between the exposure pattern and each edge of the design pattern and comparing the distance with a predetermined threshold. However, due to the existence of the optical diffraction effect, the light diffraction effect is particularly obvious at the positions where the figures are adjacent to each other, especially at the top of the line segment and the corner of the figure. Based on the above phenomenon, after a lot of experiments and research, the inventor proposes the optical proximity correction method of the present invention, corrects the outline of the design figure according to the principle of optical diffraction to obtain the desired figure, and then compares the exposure figure with the desired figure instead of the design figure For comparison, the distance between corresponding edges in the two is calculated, and the distance is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com