Light-emitting device

A technology for light-emitting devices and light-emitting elements, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of uneven temperature distribution of light-emitting element groups, easy reduction of light-emitting efficiency, reliability and lifespan, etc., so as to improve the light-emitting efficiency and Effectiveness of reliability, simplification of structure, and suppression of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

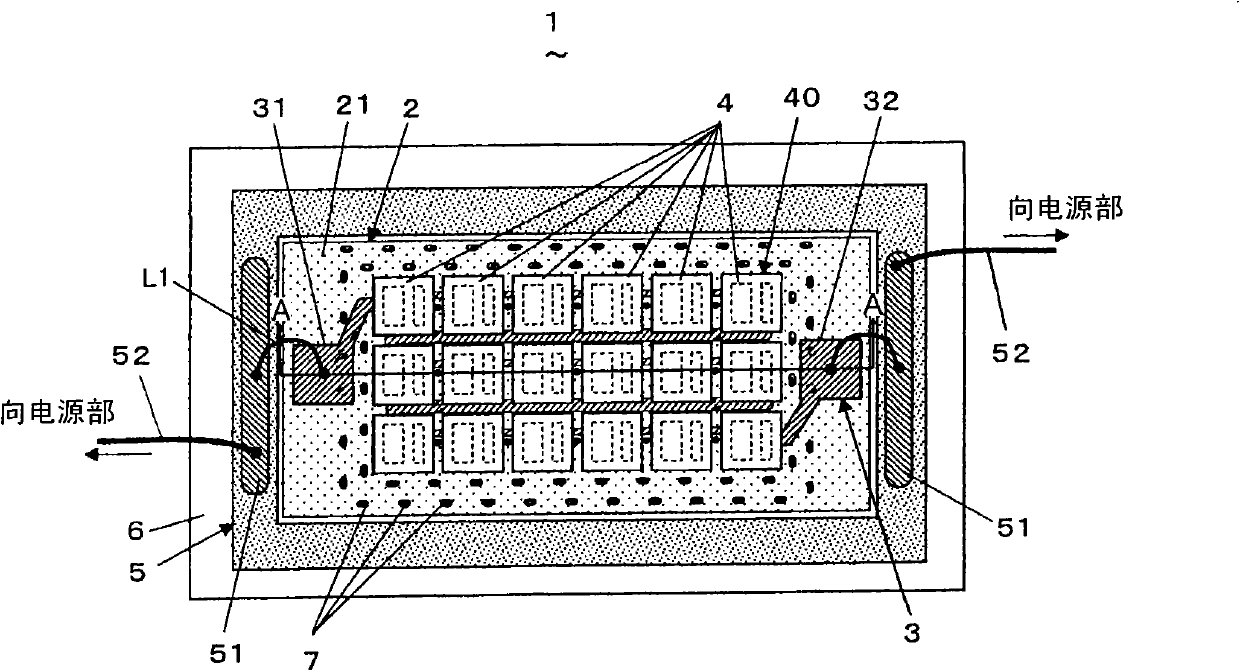

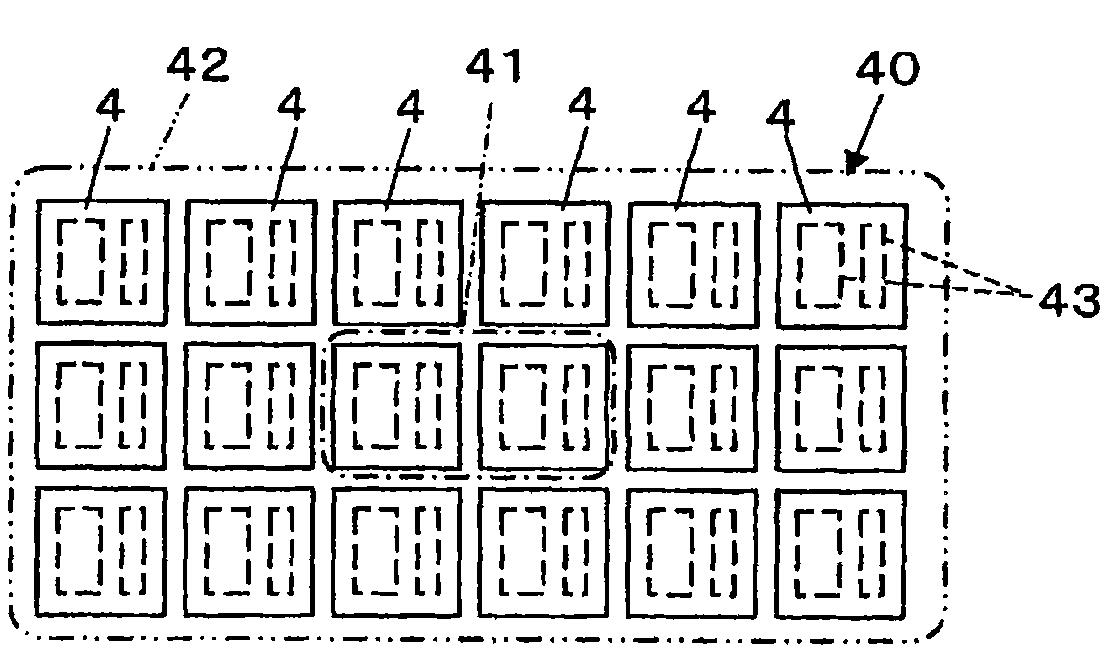

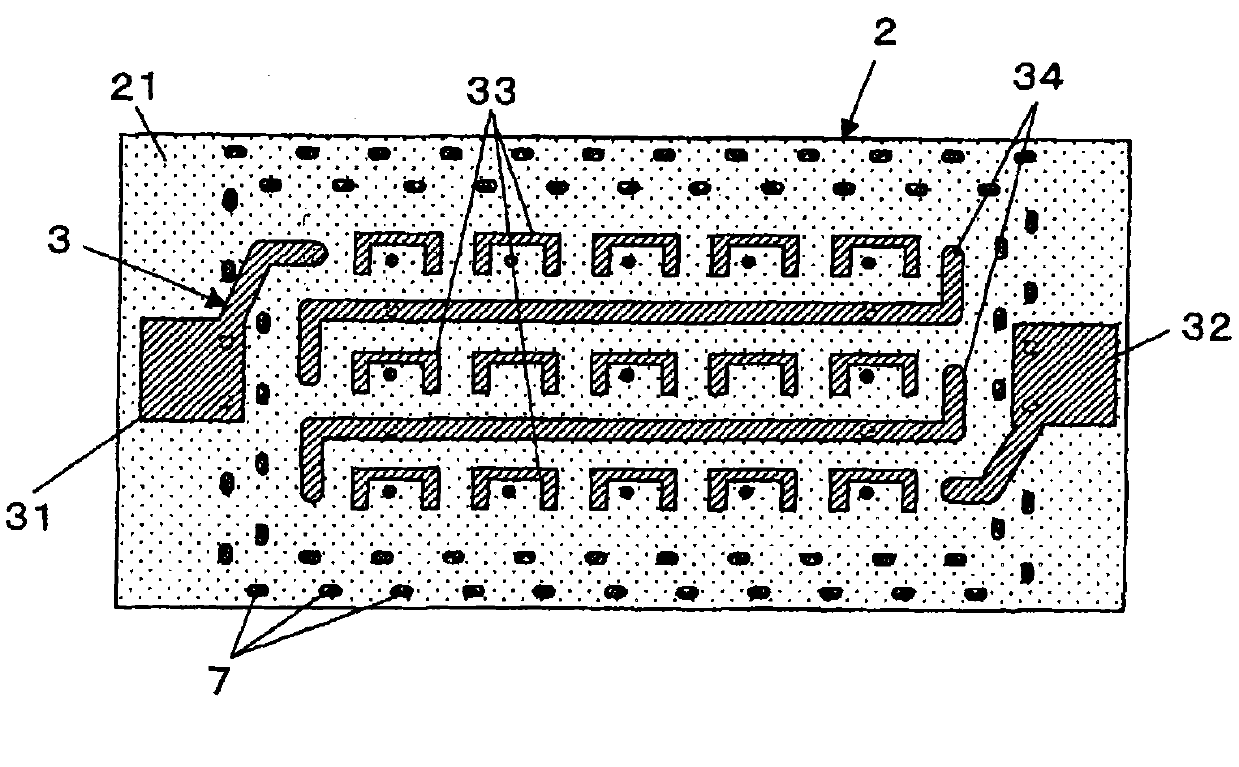

[0032] Below, refer to Figure 1 to Figure 4 A light emitting device according to a first embodiment of the present invention will be described. figure 1 Showing the structure of the light emitting device 1 of this embodiment, figure 2 shows the arrangement structure of the light emitting element group 40 of the light emitting device 1, image 3 A wiring pattern on the mounting substrate 2 of the light emitting device 1 is shown. The light emitting device 1 includes an insulating mounting substrate 2, a wiring pattern 3 mounted on the element mounting surface 21 of the mounting substrate 2, and a plurality of (here, 18) light emitting elements 4 mounted on the wiring pattern 3. The light-emitting element group 40 constituted, the frame-shaped wiring board 5 for supplying power to the light-emitting element 4 , and the heat sink 6 for dissipating heat from the mounting board 2 and the wiring board 5 . Mounting board 2 and wiring board 5 are mounted on heat sink 6 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com