Horizontal cyclone dust collector

A dust collector and swirl technology, which is applied in swirl devices, devices whose axial directions of swirl can be reversed, etc., can solve the problems of affecting the dust removal efficiency of dust-laden flue gas, lack of air intake effect, and large air intake resistance. , to achieve the effect of improving the air intake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

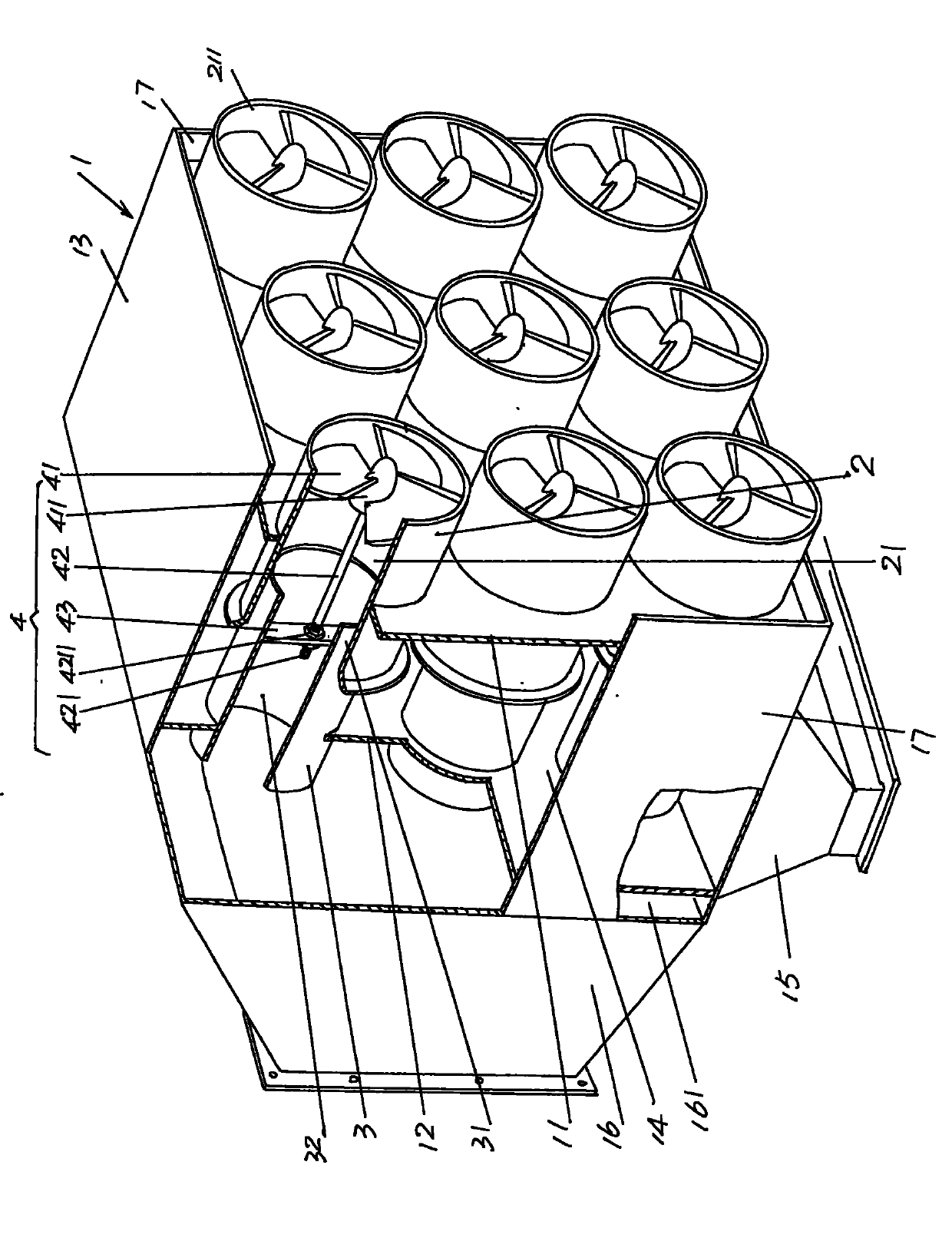

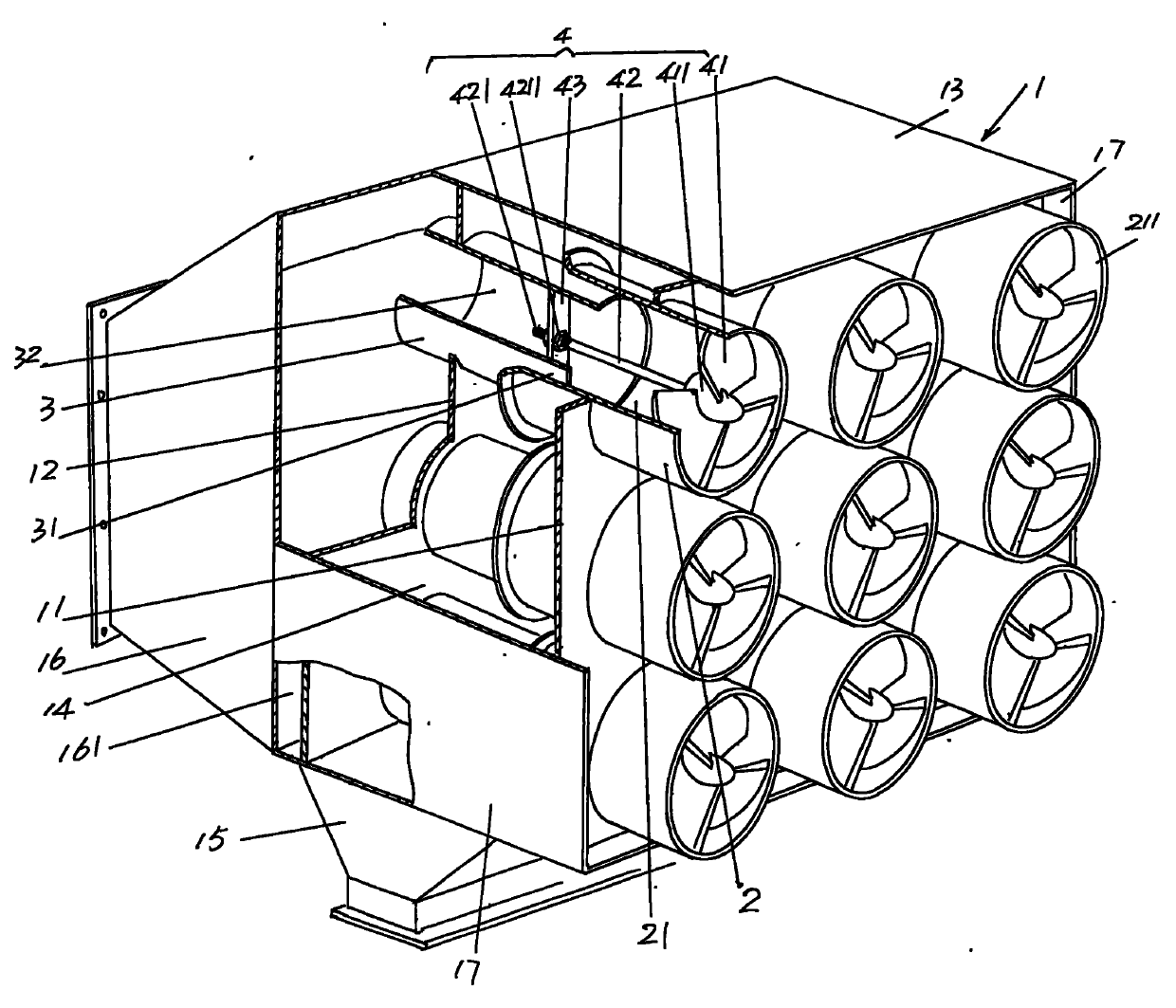

[0017] please see figure 1 , the size of the given box 1 is not limited by the illustration, the number of the air inlet cylinder 2, inner sleeve 3 and guide 4 shown in the illustration increases with the increase of the box 1, and decreases with the shrinkage, Therefore, the solution of the present invention cannot be limited by the illustrated quantity. Casing 1 is made of front and rear box walls 11,12 and top wall 13 and side walls 17 on both sides, the space between front and rear box walls 11,12 constitutes box cavity 14, corresponding to box cavity 14 The front and rear box walls 11 and 12 of the bottom are connected with a dust hopper 15 as a carrier, and the dust hopper 15 gradually narrows outwards from the bottom of the box cavity 14 to form a truncated cone. An air outlet bucket 16 is connected to the rear box wall 12 , and a stabilizing chamber 161 is reserved between the rear box wall 12 and the air outlet bucket 16 , and the stabilizing chamber 161 helps to imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com