Guide sleeve of numerical control turret punch press upper die

A CNC turret punch and guide sleeve technology, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of long processing time, increased number of parts and low reliability, etc., to save man-hours and reduce the number of , the effect of high reliability

Inactive Publication Date: 2011-04-06

YANGZHOU HENGDE IND TECH CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the guide sleeve of the prior art, in order to improve the lubrication condition between the outer cylindrical surface and the turret station, a threaded oil groove is set on the outer cylindrical surface, but it is difficult to process this type of oil groove, and the processing time is long

In addition, in the guide sleeve in the prior art, in order to connect the binder plate of its lower edge, a plurality of symmetrical elastic pieces are arranged on the circumference to prevent the binder plate from falling, although it can facilitate the removal of the binder plate. , installed, but the number of parts of the entire upper mold assembly increases, and the reliability of the connection is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

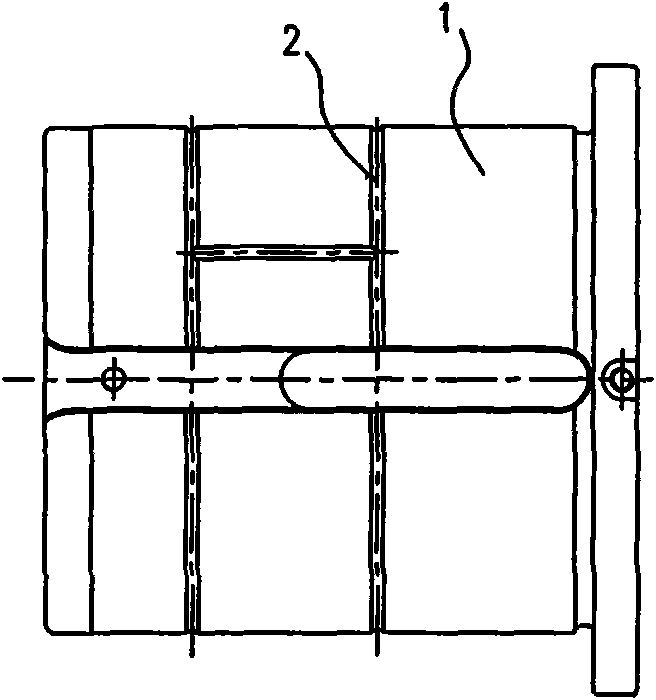

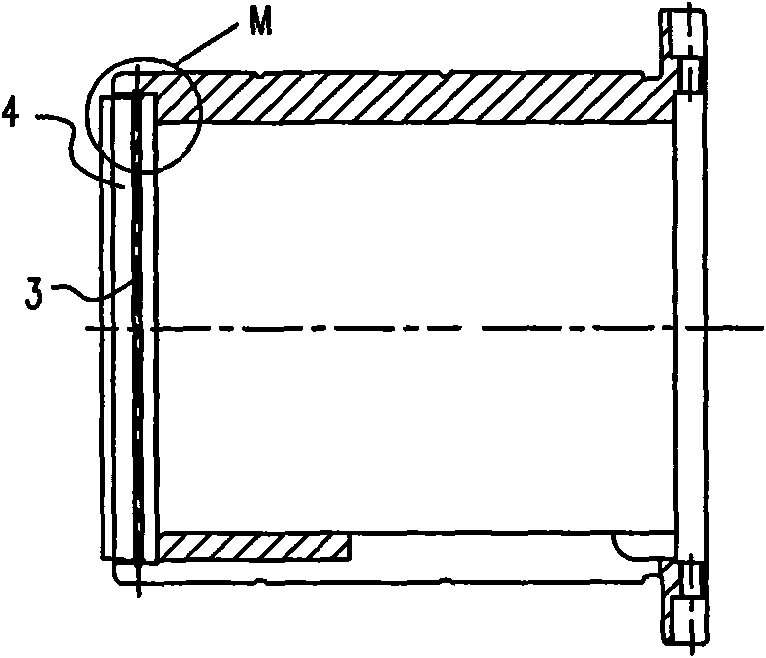

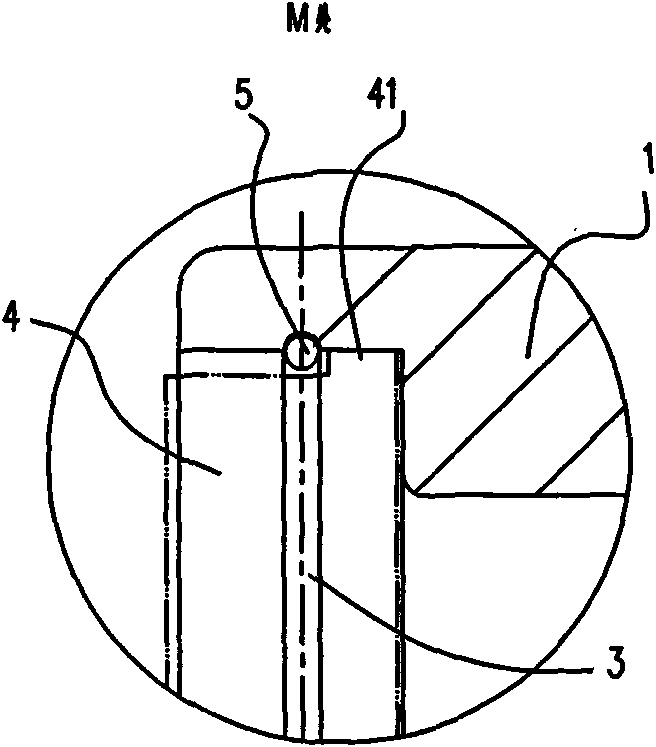

[0013] The present invention as Figure 1-3 As shown, the body 1 is cylindrical, with a shoulder at the upper end, and an inner step circle for connecting the pressure plate 4 at the mouth of the lower end, and an H-shaped oil groove 2 is provided on the outer cylindrical surface of the body 1 .

[0014] A circle of ring grooves 3 for accommodating ring rings 5 is provided on the inner step circle.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a guide sleeve of a numerical control turret punch press upper die and relates to improvement on a structure of the guide sleeve of the numerical control turret punch press upper die. A main body is cylindrical; the upper end of the main body is provided with a circular bead; an inner step circle connected with a material pressing board is arranged on the cylindrical opening of the lower end of the main body; and the outer cylindrical surface of the main body is provided with an H-shaped oil groove. As the lubricating oil groove is changed to be H-shaped, the guide sleeve meets the requirement of axial lubrication and makes the machining of such an oil groove more convenient, thereby greatly saving the working time. Furthermore, a clamp spring groove is formed on the lower cylindrical opening; of course, the structure of the material pressing board has a tiny change, namely a step circle and a circumferential concave groove are added; by the clamp spring connection, the material pressing board is convenient to demount and mount; at the same time, compared with the original multi-elastic-sheet structure, the invention has the advantages that: the guide sleeve is easier to process; and during use, the guide sleeve has higher reliability and reduces the amount of accessories.

Description

technical field [0001] The invention relates to the improvement of the structure of the mold guide sleeve on the numerically controlled turret punch press. Background technique [0002] In the guide sleeve of the prior art, in order to improve the lubrication condition between the outer cylindrical surface and the turret station, a threaded oil groove is set on the outer cylindrical surface, but it is difficult to process this type of oil groove, and the processing time is long . In addition, in the guide sleeve in the prior art, in order to connect the binder plate of its lower edge, a plurality of symmetrical elastic pieces are arranged on the circumference to prevent the binder plate from falling, although it can facilitate the removal of the binder plate. , installed, but the number of parts of the entire upper mold assembly increases, and the reliability of the connection is low. Contents of the invention [0003] Aiming at the above problems, the present invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/14B21D22/02

Inventor 庄瑞斌吕万长

Owner YANGZHOU HENGDE IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com