Low-shrink anchorage sealing material for CRTS I type ballastless track slabs of high speed railway

A technology for ballastless track and high-speed railway, which is applied in the field of prefabricated box girder and T-beam prestressed steel bar end sealing treatment, high-speed railway CRTS I type ballastless track slab prestressed steel anchorage treatment field, and can solve the problem of sealing anchor materials Problems such as non-compactness, shrinkage cracking, and low bond strength can achieve the effects of improving impermeability and bond strength, improving impermeability, and high volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The detailed description of the embodiments: the present embodiment is carried out under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

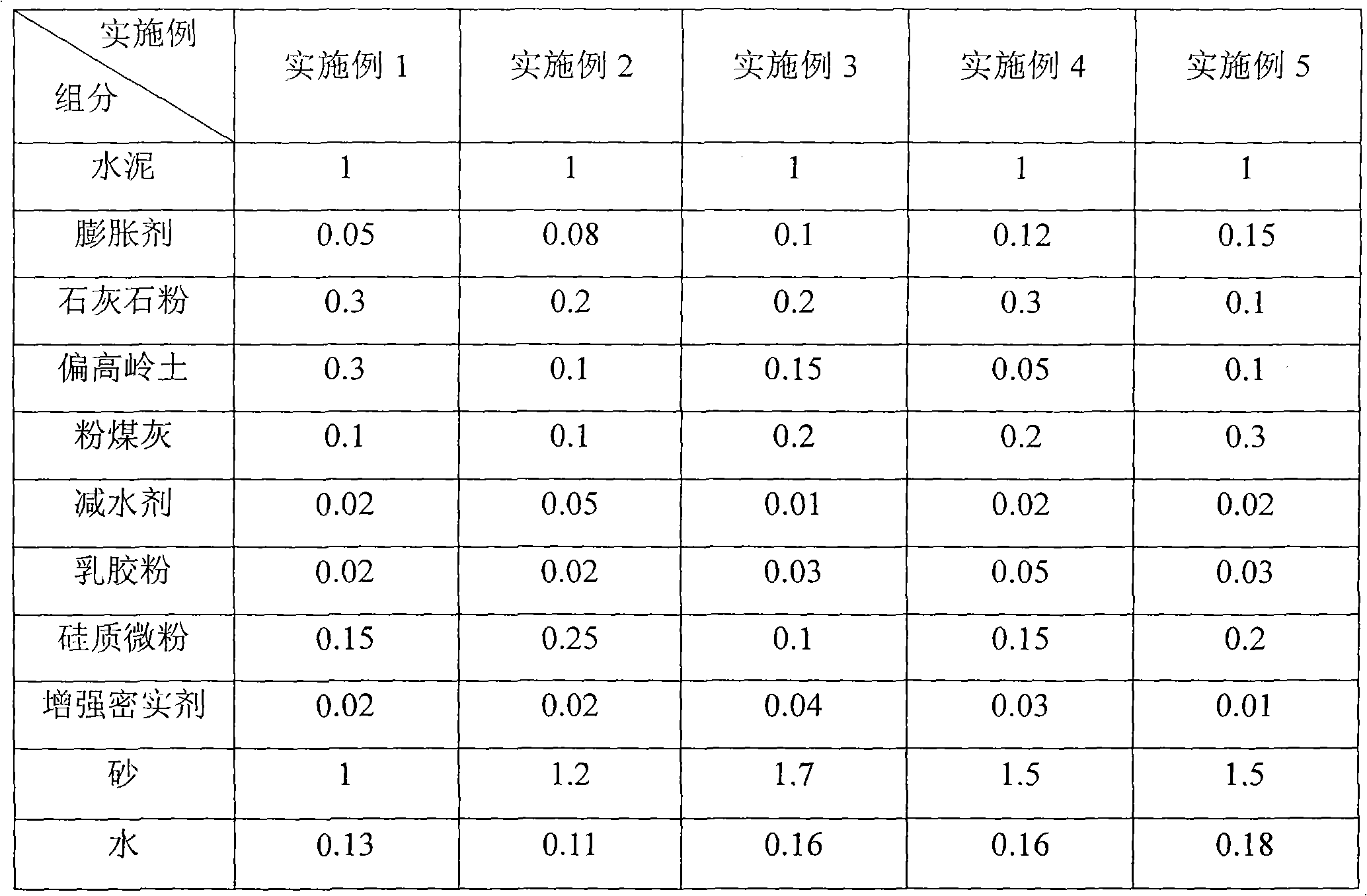

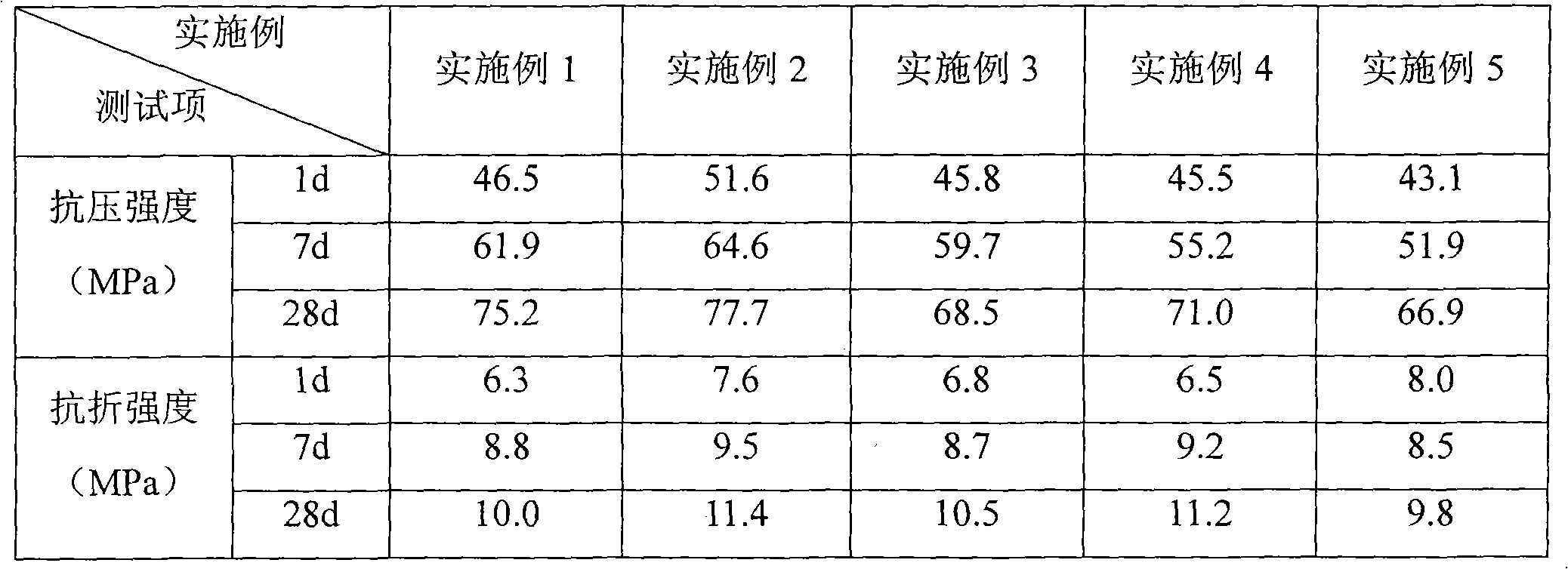

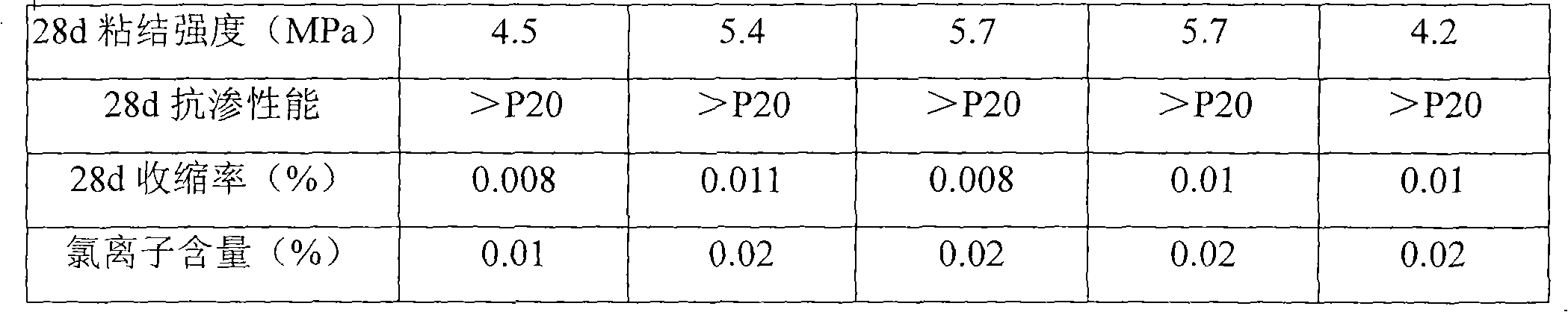

[0016] Low-shrinkage sealing and anchoring material for high-speed railway CRTS I type ballastless track slab, consisting of cement, expansion agent, limestone powder, metakaolin, fly ash, water reducing agent, latex powder, siliceous micropowder, reinforcing and compacting agent, sand , water according to a certain proportion, prepared by the following process: first weigh cement, expansion agent, limestone powder, metakaolin, fly ash, latex powder, silica micropowder according to the proportion, then add to the mixer and mix for 60s~ 240s; then add water reducing agent and reinforcing compacting agent in proportion and stir together for 120s ~ 300s; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com