Manufacturing method of synchronizer tooth link

A synchronizer gear ring, technology of manufacturing method, applied to components with teeth, belt/chain/gear, portable lifting device, etc., to achieve the effect of stable quality and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Set forth below the synchronizer ring structure of the present invention and the detailed manufacturing process:

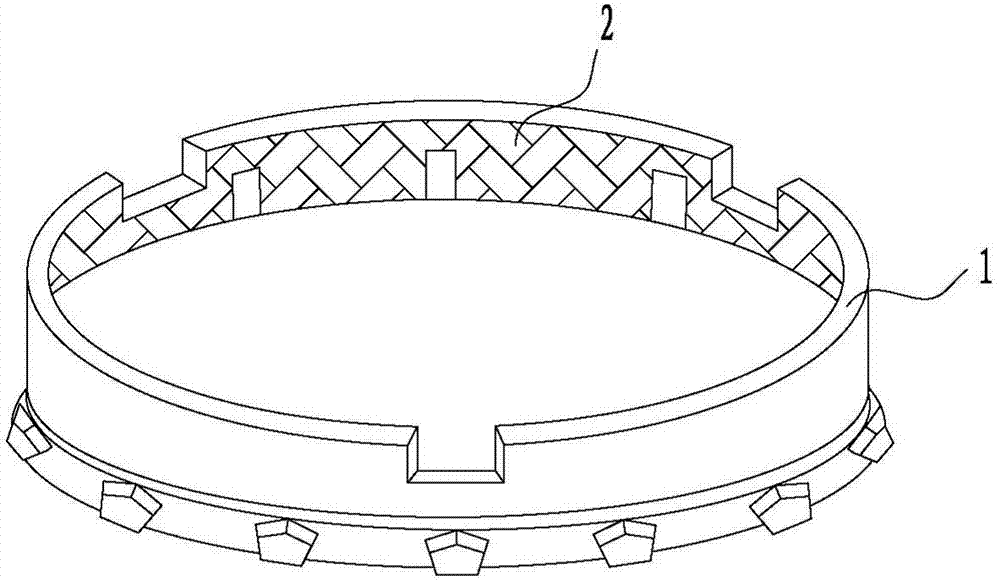

[0015] Such as figure 1 The synchronizer gear ring shown has an annular gear ring base 1 made of metal, and the metal material is usually steel. Carbon fiber cloth 2 is bonded to the inner peripheral wall of the gear ring base 1 (some specifications of synchronizer gear rings are on the outer peripheral wall of the gear ring base).

[0016] The manufacturing method of the synchronizer gear ring includes two steps: a bonding process and a curing process.

[0017] The specific process of the bonding process is as follows:

[0018] (1) Apply glue on both sides of the carbon fiber cloth, the glue content of the glue is 23%-28% (weight content);

[0019] (2) Dry the carbon fiber cloth. After drying, the warp and weft yarns in the carbon fiber cloth can be glued together.

[0020] (3) Cutting the carbon fiber cloth, the size of the cut carbon fiber cloth is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com