Motor stator piece punching blanking stamping technology and key die thereof

A technology of punching and blanking, stator and rotor, which is applied in the manufacture of stator/rotor body, etc., to achieve obvious effects, avoid waviness, and reduce stamping steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

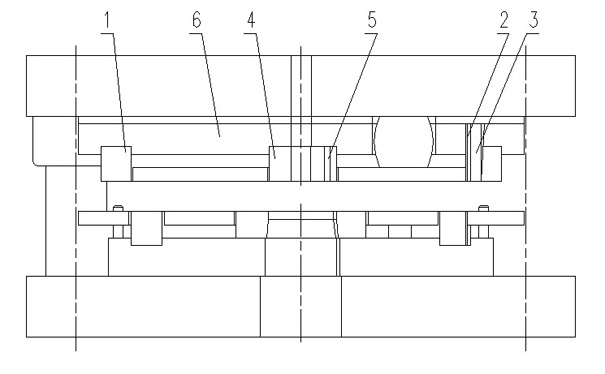

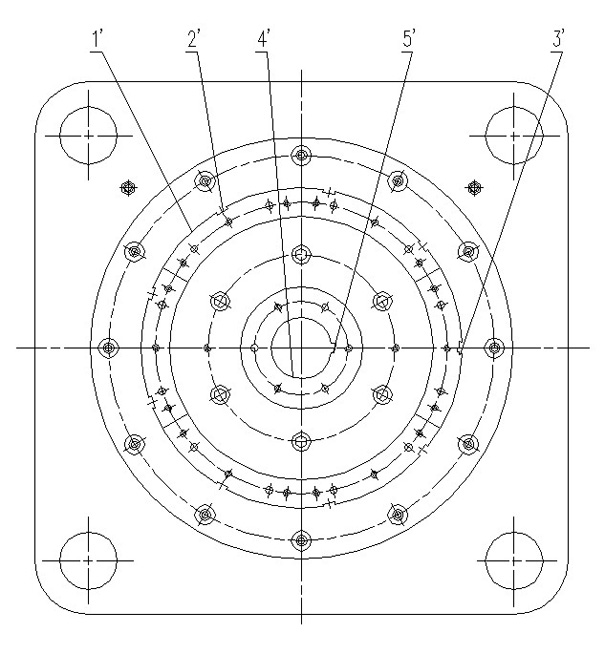

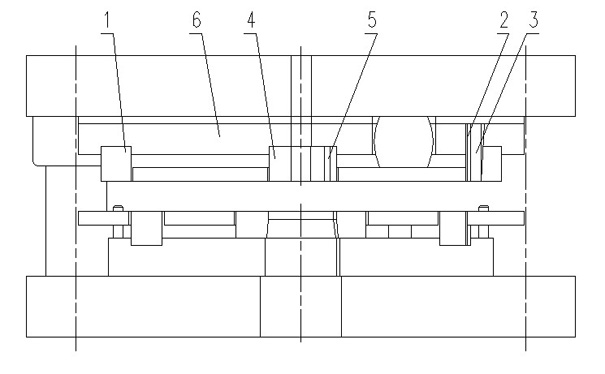

[0028] In an embodiment of the punching and blanking stamping process of motor stator and rotor sheet and its key mold provided by the present invention, the stamping process includes the following steps:

[0029] ① Re-punching the outer circle of the stator and the rotor shaft hole: on the punching machine, punch the outer circle of the stator, the slot of the stator buckle and the outer marking groove of the stator, and at the same time punch the shaft hole of the rotor and the keyway of the rotor to obtain the blank of the stator and rotor;

[0030] ②Single punch stator slot: On the single slot machine, position the stator and rotor blank with the rotor shaft hole and the rotor keyway, single punch the stator slot, and get the stator and rotor blank with the stator slot punched;

[0031] ③Single punching of rotor slots and separation of stator and rotor slices: On the single slot machine, the stator and rotor blanks punched with stator slots are positioned with the rotor sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com