All-vanadium flow battery

An all-vanadium redox flow battery and liquid flow technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of increasing the thickness of the conductive plate, increasing the internal resistance, and increasing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

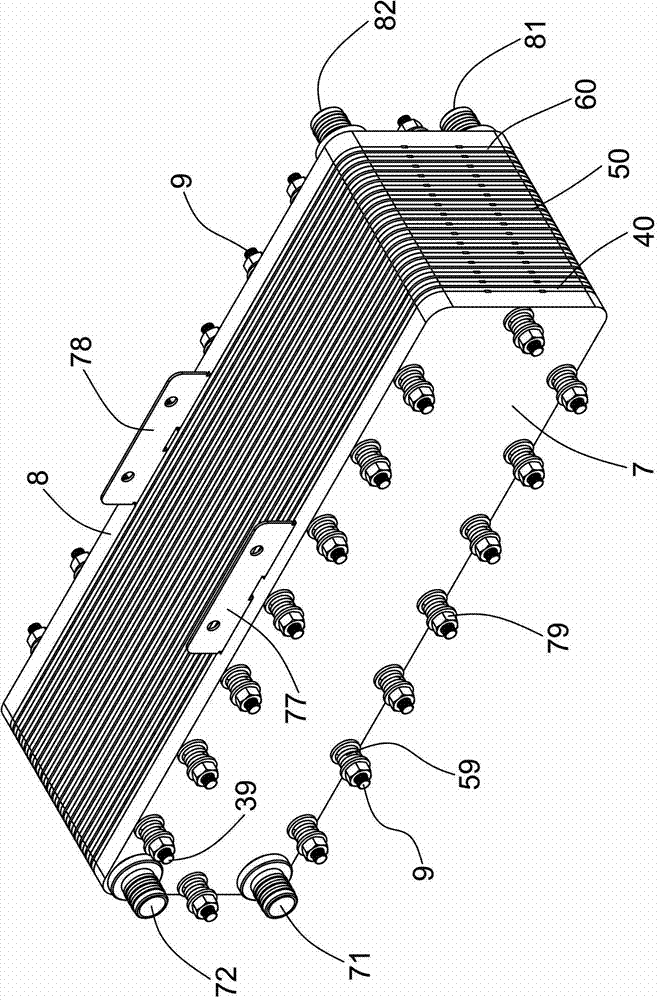

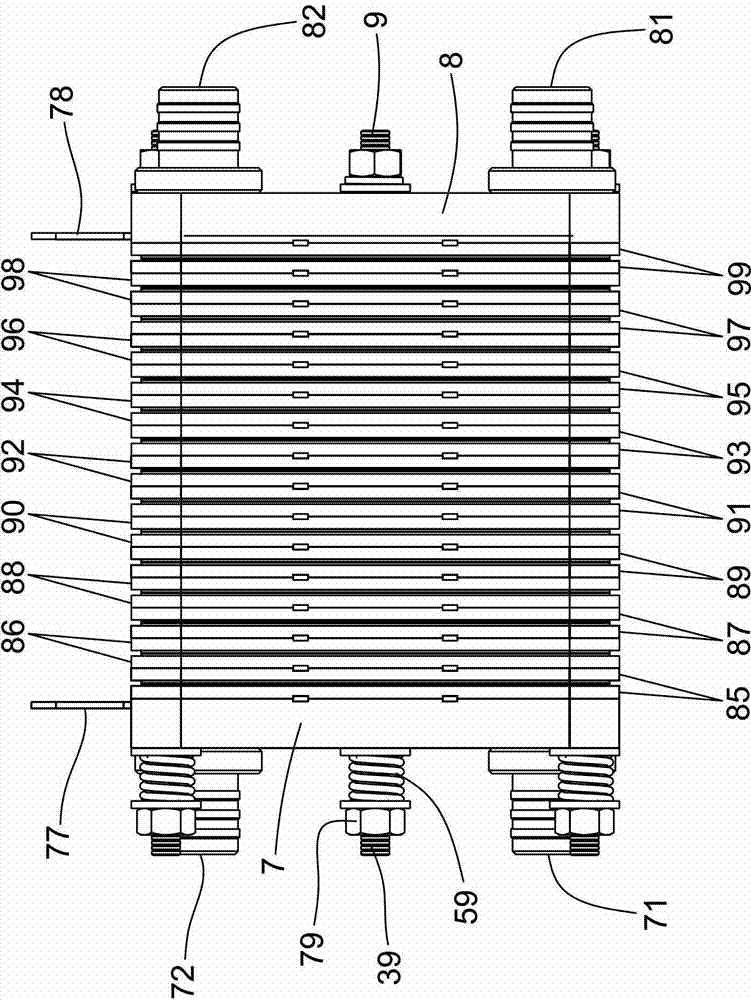

[0095] Labels in the figure:

[0096] 1 Positive flow frame plate 2 Negative flow frame plate 3 Conductive plate

[0097] 4 positive electrode 5 ion exchange membrane 6 negative electrode

[0098] 7 Positive end pressure plate 8 Negative end pressure plate 9 Fasteners

[0099] 10 inner frame 11 liquid inlet hole 12 liquid outlet hole

[0100] 13 Liquid outlet hole 14 Liquid outlet hole 15 Locking pin

[0101] 16 Locking hole 17 Cover plate 18 Cover plate

[0102] 19 Annular concave table 20 Inner frame 21 Liquid inlet hole

[0103] 22 Liquid hole 23 Liquid hole 24 Liquid outlet

[0104] 25 locking pin 26 locking hole 27 cover plate

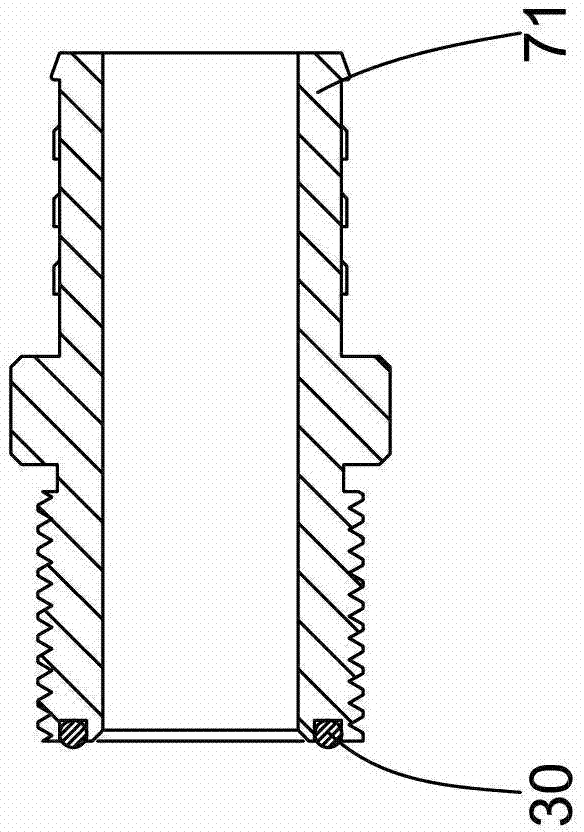

[0105] 28 cover plate 29 annular concave platform 30 sealing ring

[0106] 31 branch flow channel 32 narrow comb groove 33 long straight groove

[0107] 34 narrow comb slot 35 positioning pin 36 positioning hole

[0108] 37 long straight slot 38 wide comb slot 39 screw rod

[0109] 40 Positive electrode assembly 41 Branch channel 42 Narr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com