Ultrasonic cleaning system

A cleaning system and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of reducing the life of the vibration plate, increasing the load of the vibration plate, and reducing the efficiency, and achieve uniform cleaning. , uniform vibration, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

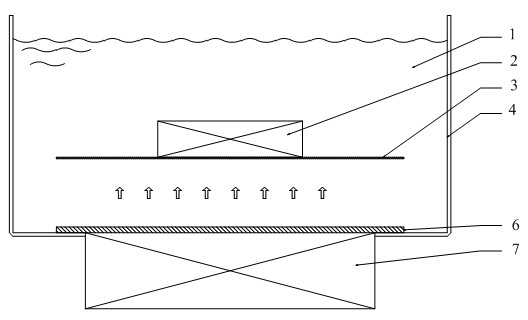

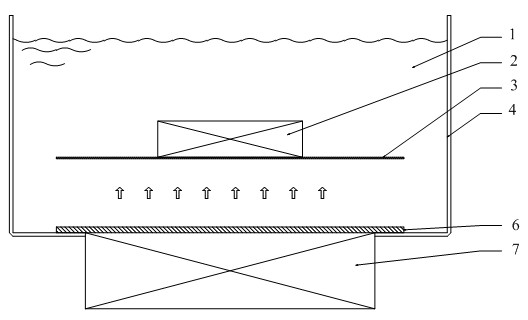

[0026] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0027] Such as figure 1 As shown, an ultrasonic cleaning system includes: a water tank 4 for containing liquid, an ultrasonic generating unit arranged at the bottom of the water tank 4, and a load for carrying the items 2 to be cleaned inside the water tank 4 Unit 3.

[0028] The carrying unit 3 includes a carrying net that is stretched and used to carry the articles to be cleaned.

[0029] The bag net is fixed on a frame that can provide tension, and the tension ranges from 10 to 60 N / cm, preferably 35 N / cm. The material of the bag net can be stainless steel, nylon, polyester and silk, preferably stainless steel. The weaving mode of the pocket net can be plain weave, section weave, half twist weave, full twist weave or twill weave, and plain weave is preferred. The mesh number of the pocket net is 10 to 350 mesh, preferably 20 mesh....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com