Involute spline broach and broaching method thereof

A technology of involute splines and spline holes, which is applied to broaches, broaching machines, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

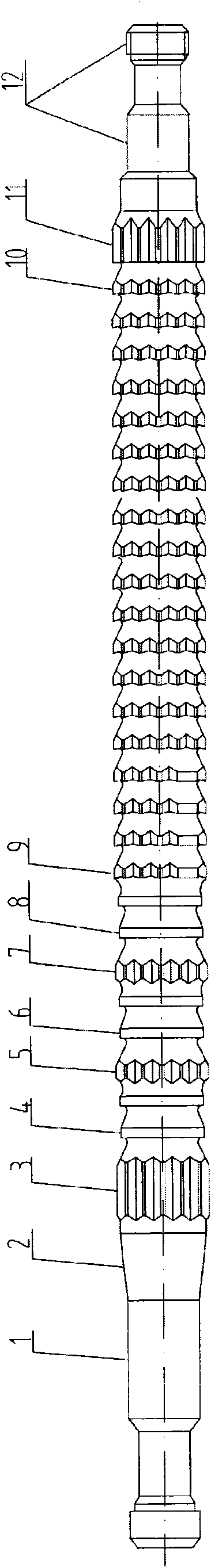

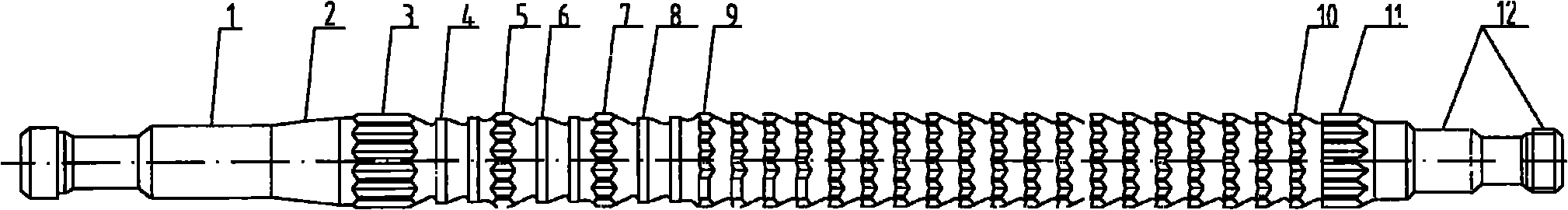

[0010] In the figure, a kind of involute spline broach of the present invention, it contains shank 1, transition cone 2, guide key 3, 5, 7, 11, cutting tooth 4, 6, 8, 9, correcting tooth 10, support Holder 12. The cutting teeth include a small inner diameter cutting tooth 4, a medium inner diameter cutting tooth 6, a large inner diameter cutting tooth 8 and a tooth-shaped cutting tooth 9, and the tooth-shaped cutting tooth 9 not only has a cutting function, but also has a guiding and positioning function. The guide key 3 on the right side of the transition cone 2 and the guide key 11 on the left side of the support portion 12 are provided with extended guide teeth. The lengthened guide key 3 on the left side of the broach is set to the right, followed by a small inner diameter cutting tooth 4, a guide key 5, a middle inner diameter cutting tooth 6, a guide key 7, a large inner diameter cutting tooth 8, and a tooth shape cutting tooth 9. Teeth 10, guide key 11, support portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com