Spring energy storage wheel

A technology of energy storage and clockwork, applied in the direction of spoked wheels, wheels, vehicle parts, etc., can solve the problems of inability to run, the wheel body does not have automatic rotation and acceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

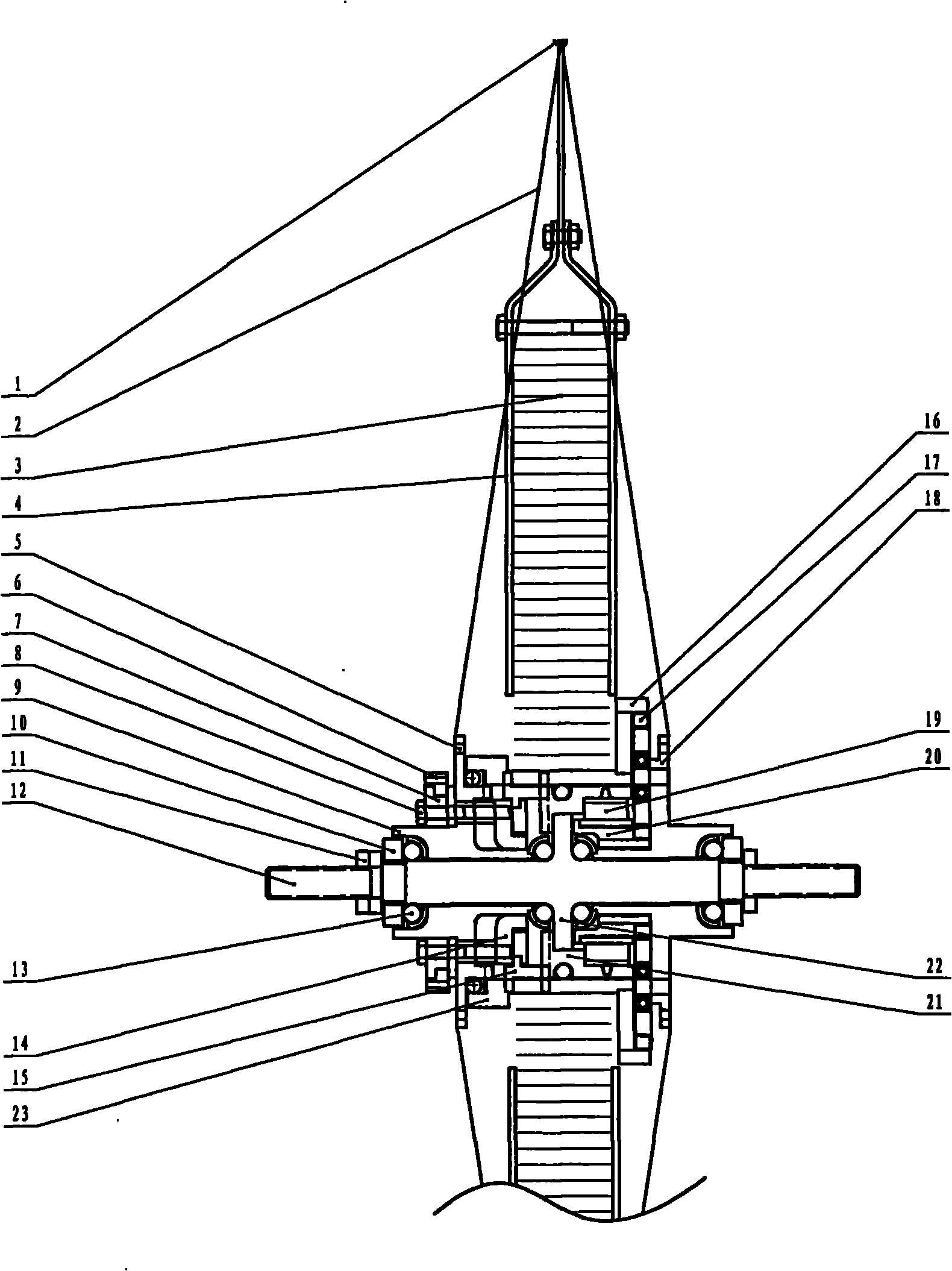

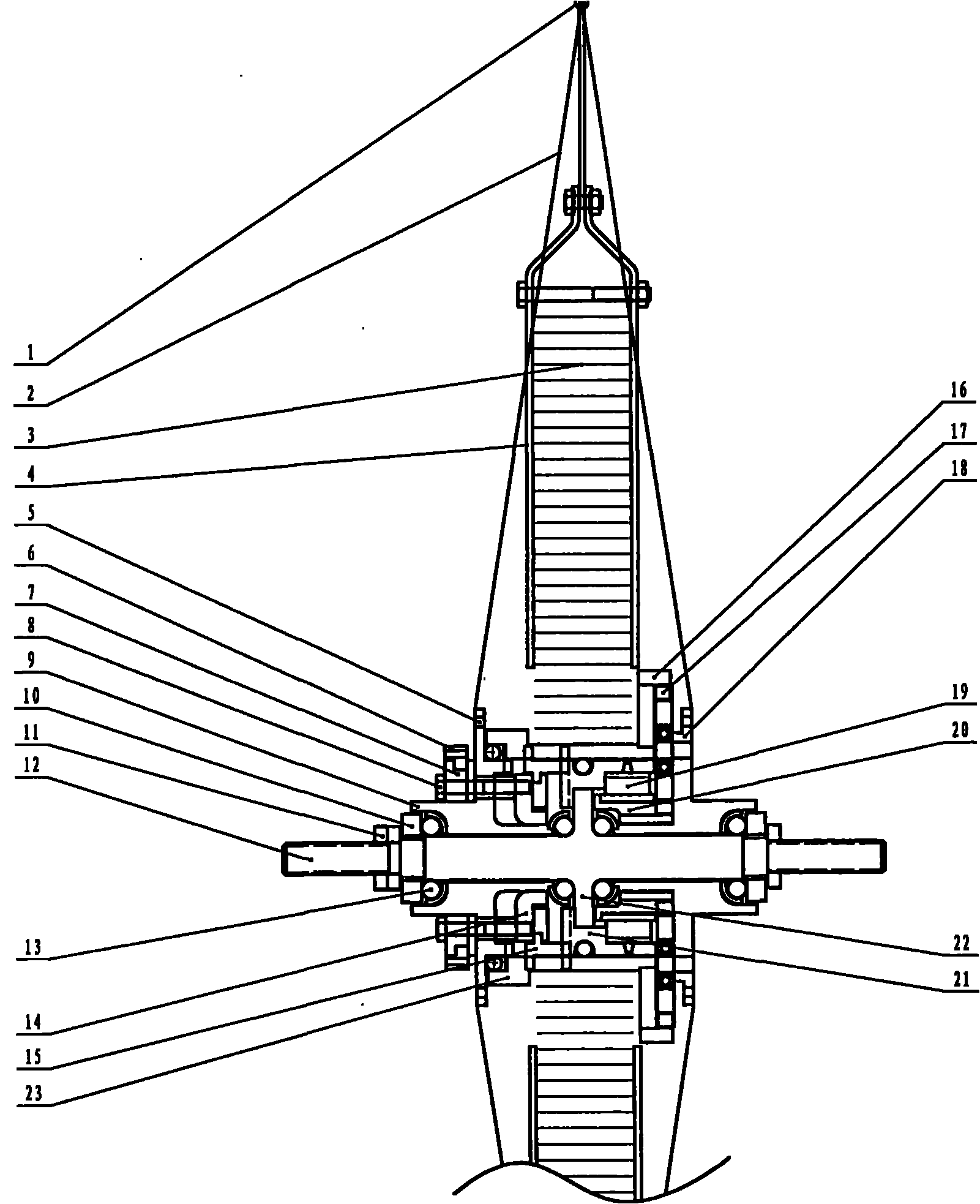

[0011] See attached figure 1 As shown, a clockwork energy storage wheel includes an energy storage wheel body, a transmission mechanism, and a control mechanism. The energy storage wheel body is provided with a transmission mechanism and a control mechanism. The left wheel hub 5, the right wheel hub 18, the spokes 2, and the rim 1 are composed of a circular disk 22 in the middle of the main shaft 12, and the circular disk 22 is covered with a shaft sleeve 21. The main shaft 12 at the two ends of the circular disk 22 The left wheel hub 5 and the right wheel hub 18 are respectively set on the top, and the left wheel hub 5 and the right wheel hub 18 are respectively slidingly connected to the main shaft 12 through the dual bearing 10, and the webs of the left wheel hub 5 and the right wheel hub 18 are connected to the rim 1 through the spokes 2. Described transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com