Method for recovering titanium tetrachloride

A technology of titanium tetrachloride and recovery tank, which is applied in the direction of titanium halide, can solve the problems of heat mismatch in the chlorination furnace system, loss of titanium tetrachloride, etc., and achieve continuous production, high recovery rate, and simple process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

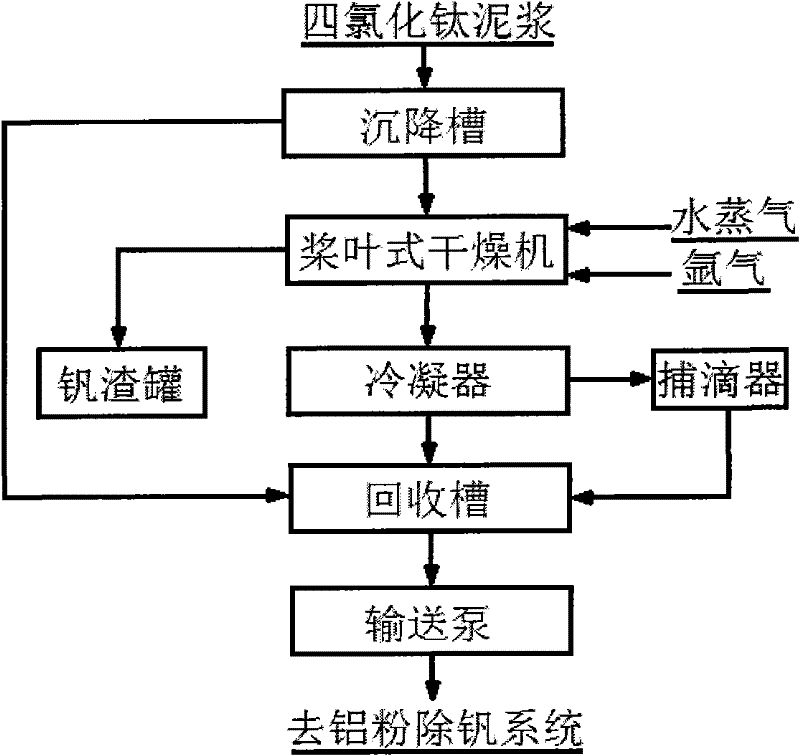

[0020] see figure 1 The process flow diagram of the present invention, the method for reclaiming titanium tetrachloride of the present invention comprises the following steps: 1) the vanadium titanium tetrachloride mud in the settling tank is by natural sedimentation, and the titanium tetrachloride clear liquid wherein is stratified with the underflow of solid mud ; 2) The titanium tetrachloride clear liquid overflows in the titanium tetrachloride recovery tank, and the solid-containing mud produced at the bottom of the settling tank flows into the paddle dryer by itself, and the paddle dryer selects 0.55~0.65MPa The steam heat source is used to heat the solid-containing mud, and the temperature is controlled at 140-148°C. Preferably, the steam pressure is 0.6MPa, and the temperature is controlled at 145°C; the temperature control can adopt an automatic adjustment method to ensure that the temperature is stable during the mud drying process. At the same time, the special struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com