Spiral hot air collector

A wind extraction heater, spiral technology, applied in the field of spiral hot air extraction heaters, can solve the problems of difficulty in ensuring the heating effect, waste of hot air heat energy, and small heat exchange area, so as to increase heat exchange efficiency and heat extraction effect, The effect of improving the heat collection effect and increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

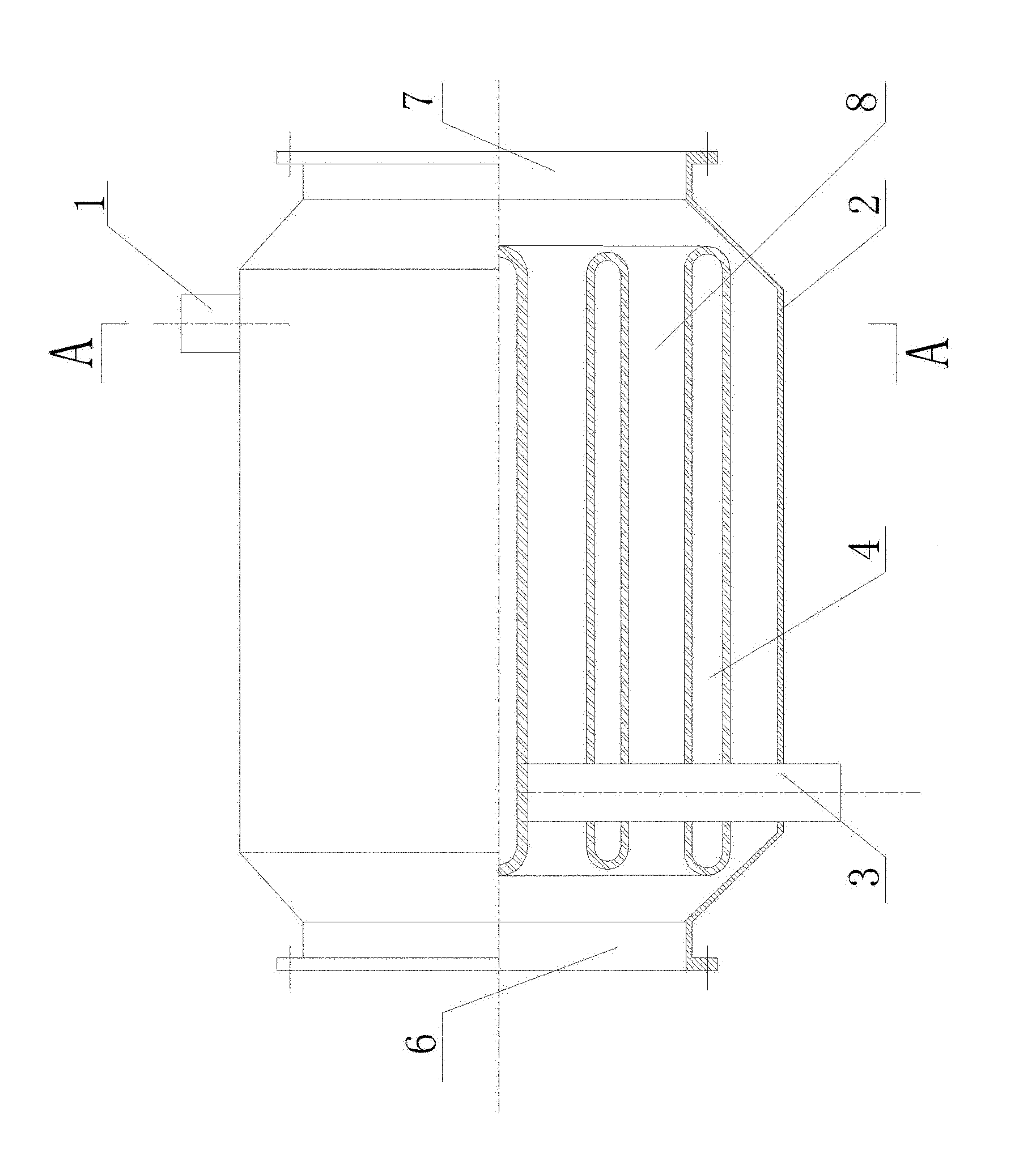

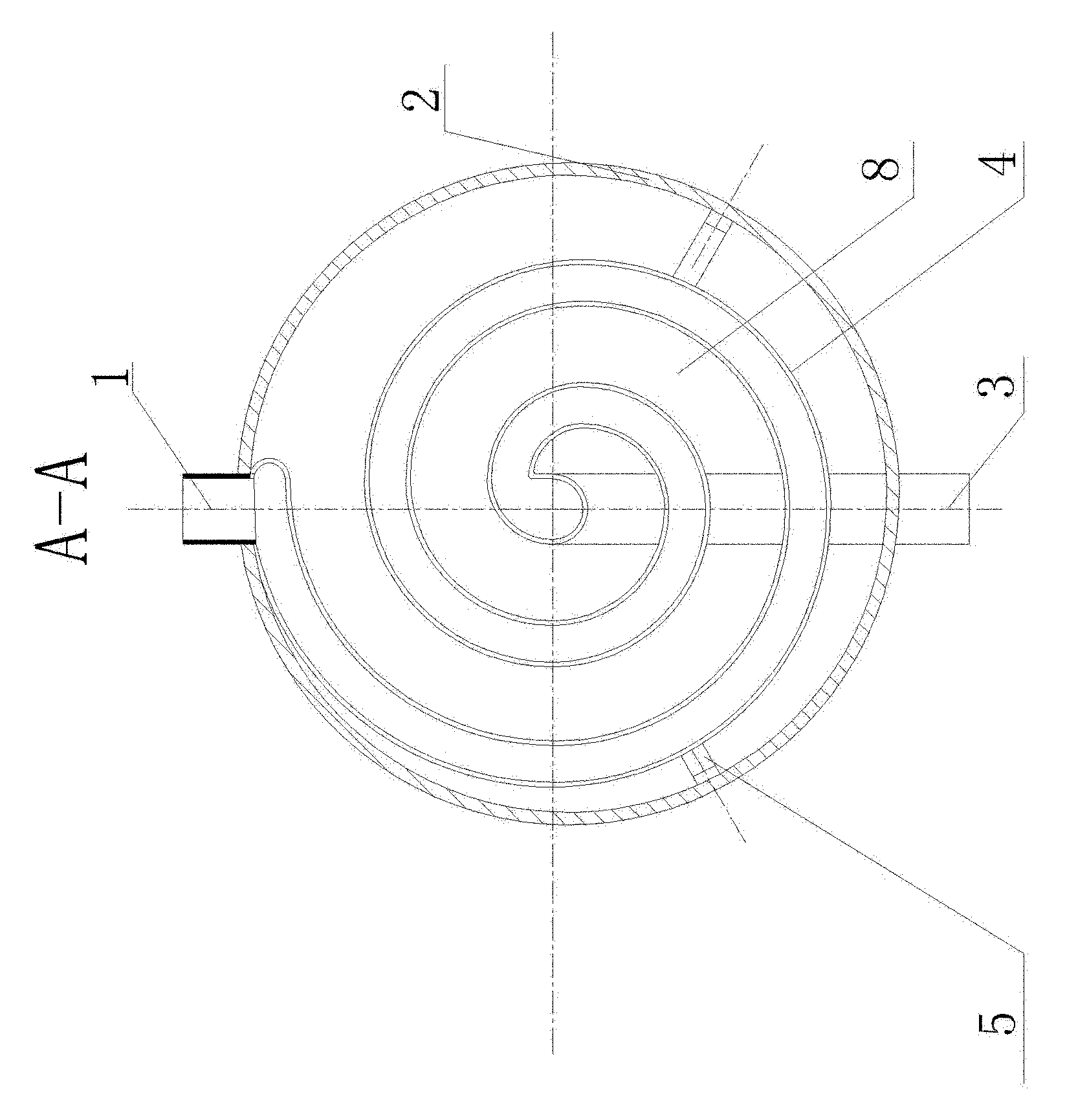

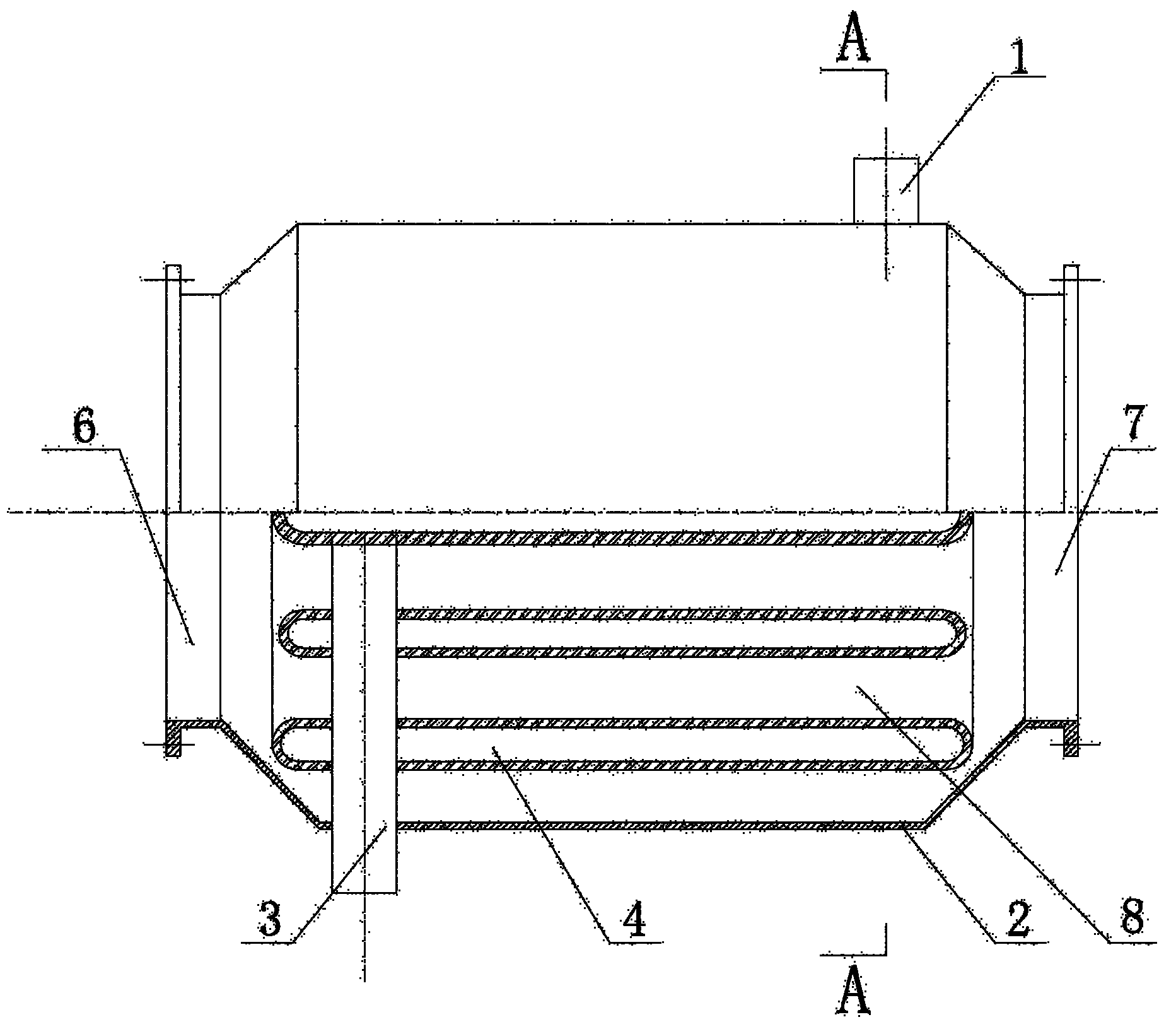

[0008] As shown in the figure, the present invention includes a casing 2 with air inlets and outlets 6 and 7 at both ends. The hollow heating belt 4 is fixed on the inner wall of the housing through a fixing bracket 5 in the housing 2 . The hollow exchanging belt 4 is spirally deployed around the axis of the casing 2, and its two side edges are streamlined to facilitate the circulation of hot air. In order to further improve the heat collection effect, the hollow heat exchange belt 4 adopts a wide-band structure, so that when the hot air with a higher temperature passes through, the water can be instantly heated into water vapor, which can be used for steam-demanding devices such as water splitters. The inner and outer ends of the hollow heat exchanger belt 4 are respectively provided with inlet and outlet ports 1 and 3 communicating with the inner cavity; gaps 8 communicated with the air inlet and outlet outlets 6 and 7 are left between the layers of the hollow heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com