Indirect heat exchange type ice crystal spread-resistant device

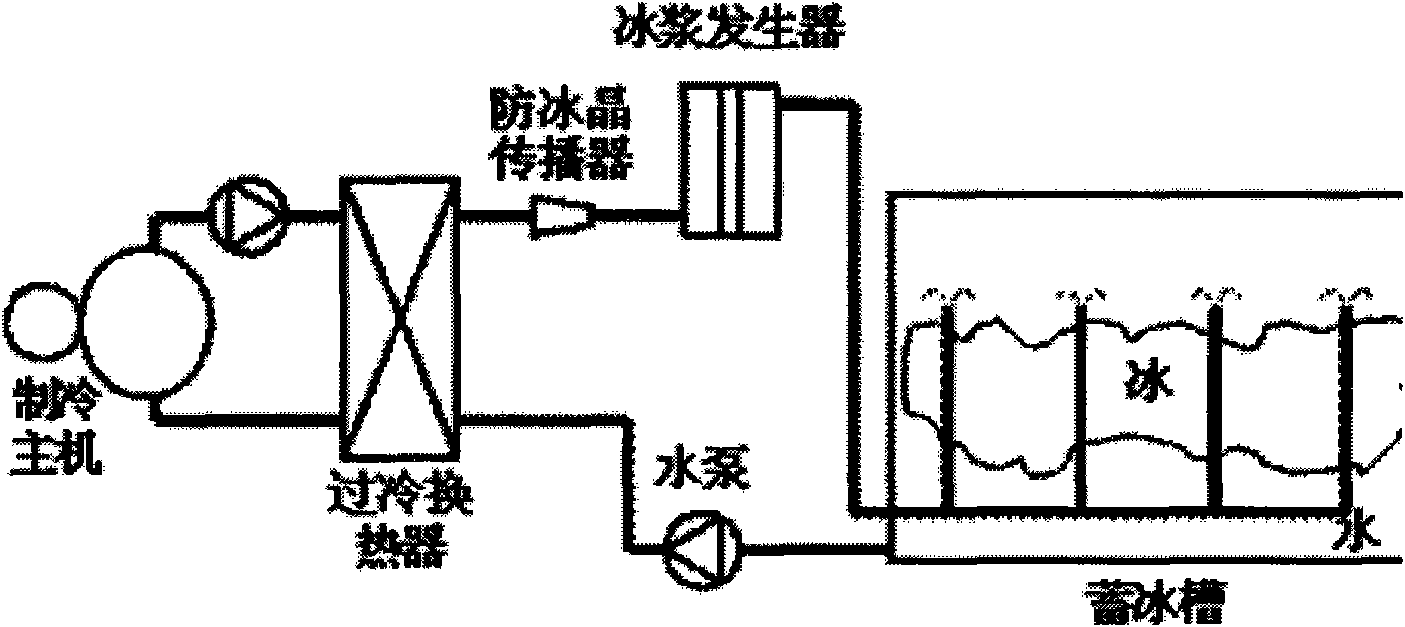

A heat exchange and ice crystal technology, which is applied in the field of indirect heat exchange anti-ice crystal spreaders, can solve the problems of interruption of ice making cycle, freezing heat exchanger, etc., and achieve the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

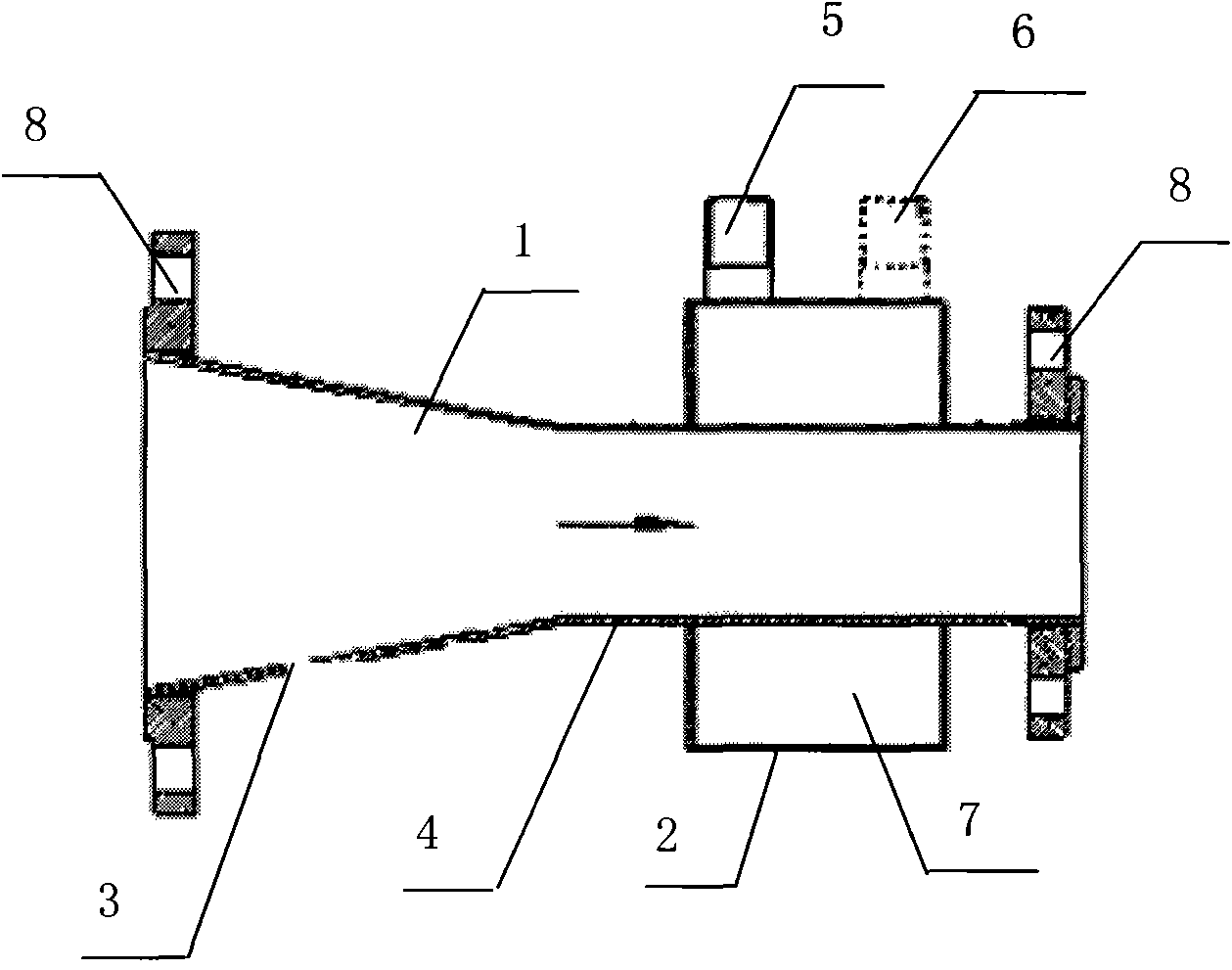

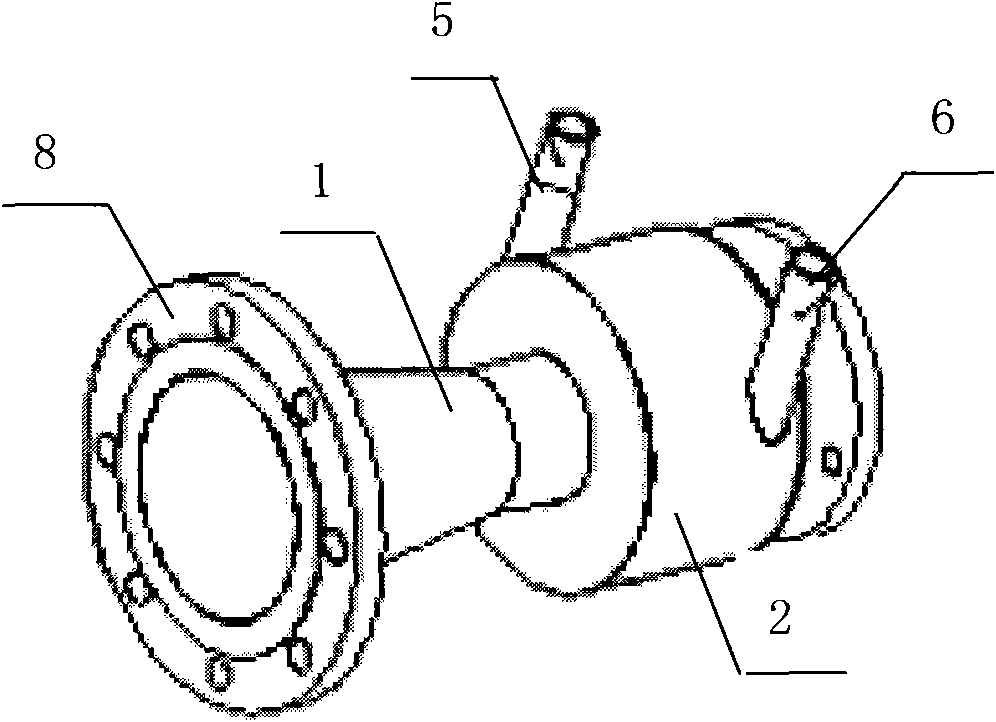

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0030] Such as figure 2 , image 3 As shown, an indirect heat exchange type anti-ice crystal spreader includes a jet tube 1 and a heat exchange tube 2, the jet tube 1 includes a speed-up section 3 at the rear end and a jet section 4 at the front end, and the heat exchange tube 2 is set outside the jet tube The jet section 4 of 1 forms a heat exchange structure with the jet section 4. Inside the heat exchange tube 2 is a heat exchange chamber 7. The heat exchange tube 2 is provided with a heat exchange inlet 5 and a heat exchange outlet 6. The heat exchange chamber 7 passes through the heat exchange The inlet 5 and the heat exchange outlet 6 communicate with the outside world.

[0031] Wherein, the inner walls of the jet tube 1 and the flow chamber wall are all provided with a hydrophobic coating; the cross-sectional area of the front end of the jet tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com