Method and device for accurately measuring and metering variable of liquid level of hydraulic container or oil cylinder

A hydraulic container, precise measurement technology, applied in the direction of container/cavity capacity measurement, measuring device, mechanical measuring device, etc., can solve the problem of inability to improve the micron level, nano level, restricting the development and application of science and technology, and the inability to measure volume and volume and other issues, to achieve the effect of reliable principle, reasonable design and high technological content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

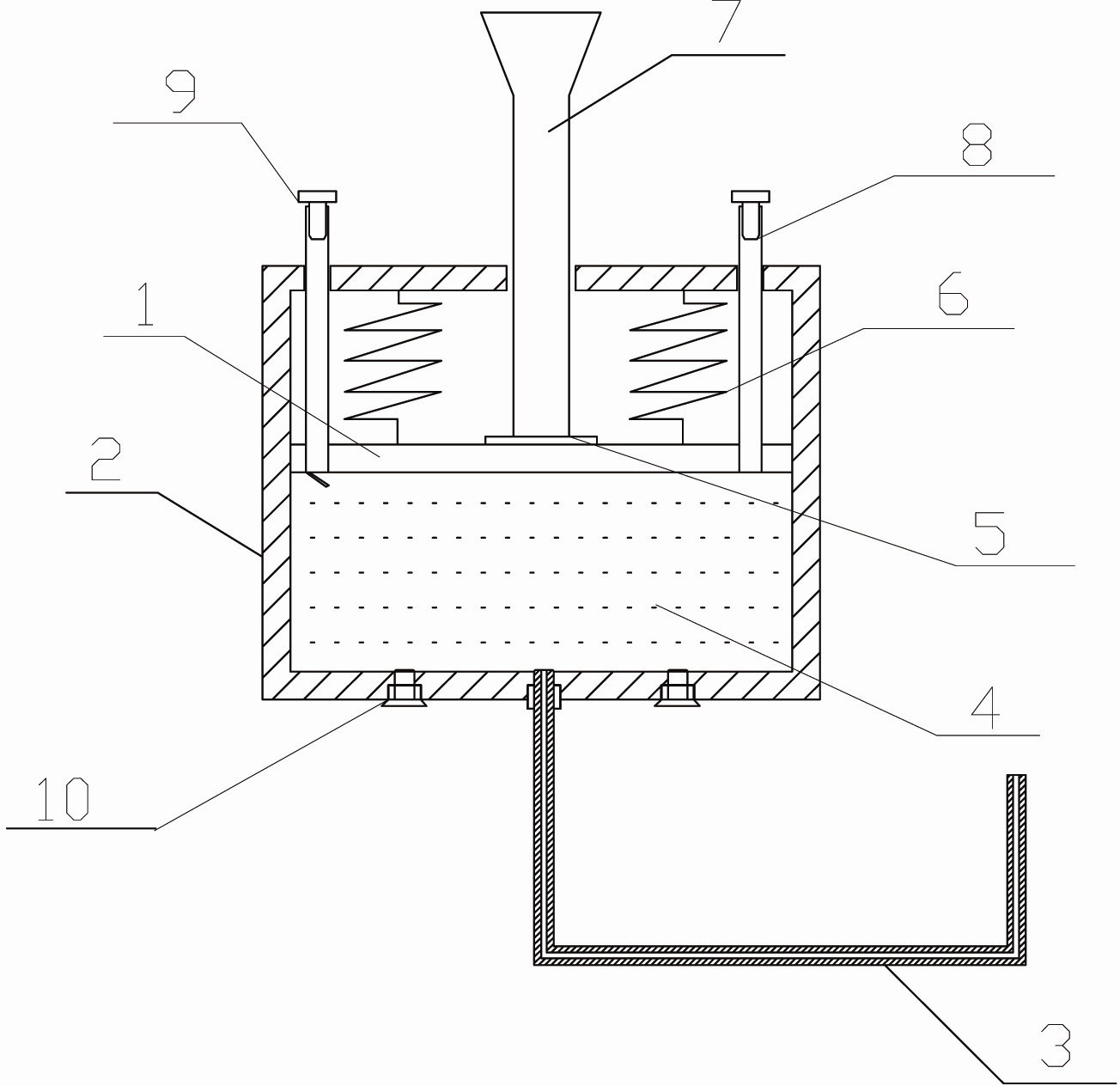

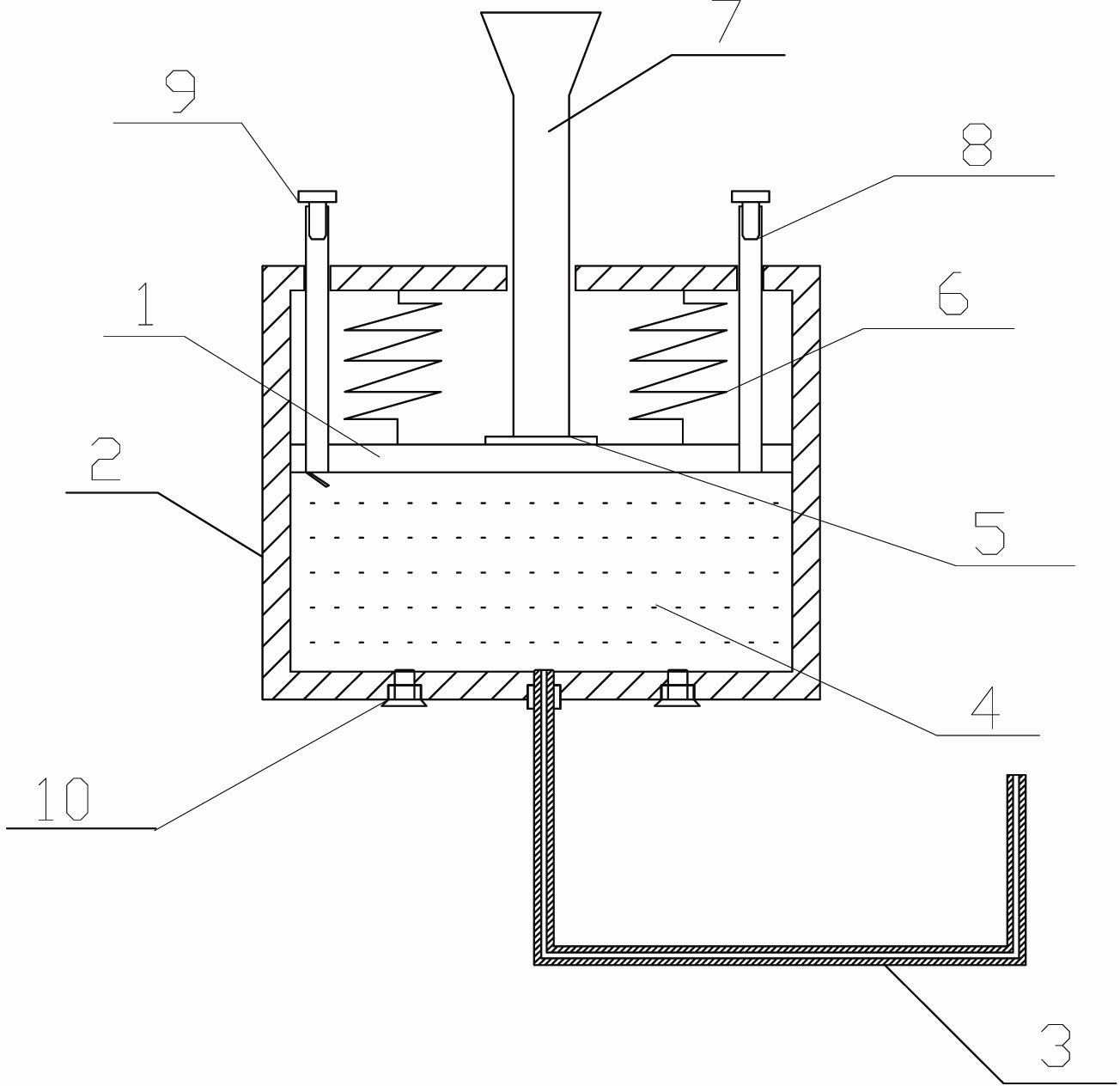

[0028] see figure 1 , The hydraulic container or oil cylinder liquid level variable of the present invention is accurately measured and measured as follows: a large-diameter hydraulic container or oil cylinder 2 equipped with a piston 1 is used, and the bottom end of the hydraulic container or oil cylinder 2 is connected to a small-diameter measuring tube 3. The hydraulic container or oil cylinder 2. Filled with hydraulic oil 4. During measurement, the piston of the large-diameter hydraulic container or oil cylinder is in contact with the object to be measured and advanced for a short distance, or the large-diameter hydraulic container or oil cylinder is placed into the measured object, and the large-diameter hydraulic container or oil cylinder. The discharged hydraulic oil enters the small-diameter measuring tube 3 to generate a displacement of a large multiple. According to the visual measurement reading ruler marked on the small-diameter measuring tube 3, the precise data of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap