Drawer push interlocking mechanism

A technology of interlocking mechanism and drawer, which is applied in the direction of pull-out switchgear, switchgear, electrical components, etc., and can solve the problem that the transmission worm and the trough-shaped turbine block cannot be self-locked, easy to produce relative displacement interlocking mechanism, and there are potential safety hazards and other problems, to achieve the effect of preventing relative displacement, improving safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

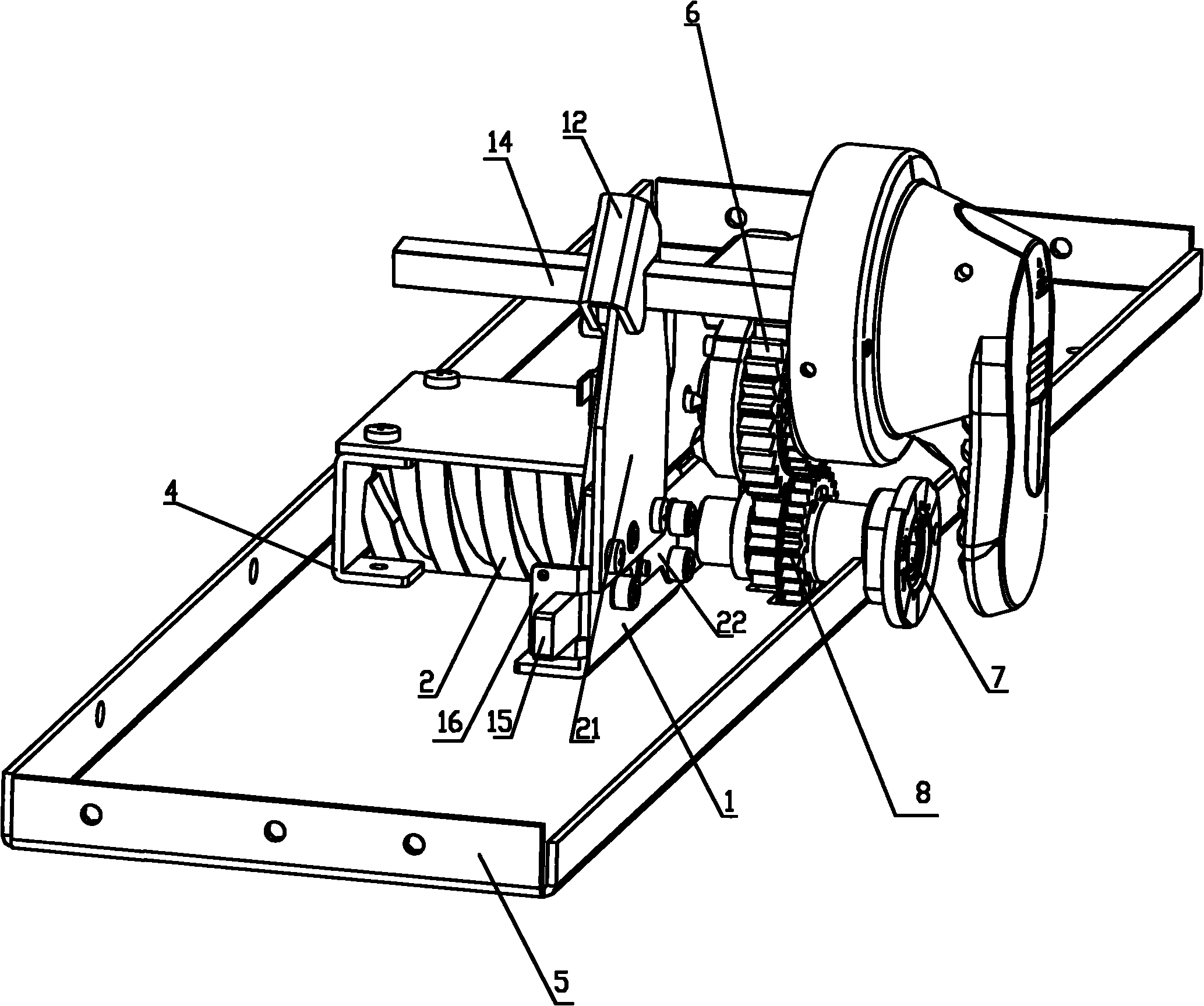

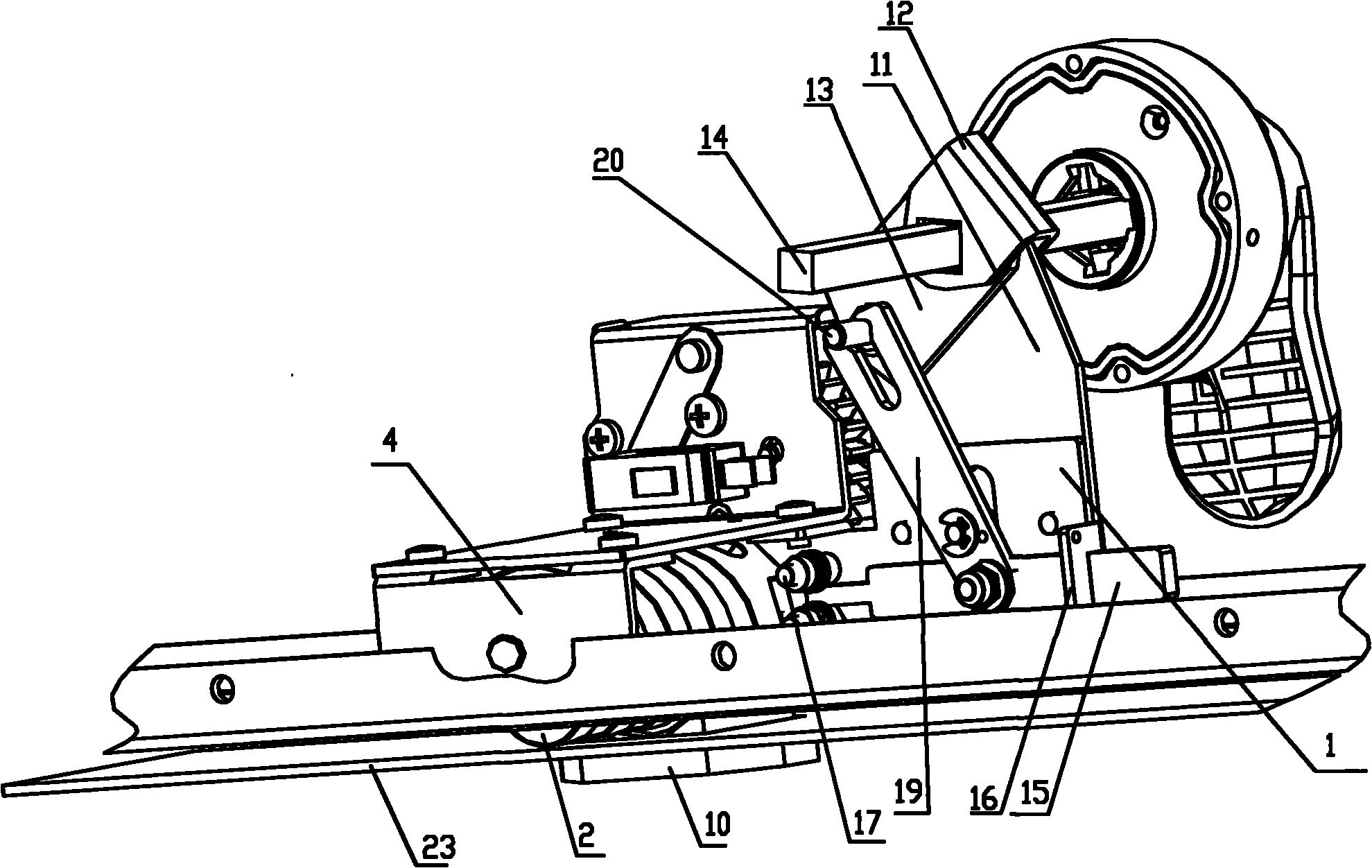

[0045] combine figure 1 and figure 2 As shown, the drawer push interlock mechanism of the present invention includes a push mechanism, a main drive wheel, a transmission positioning mechanism and a locking mechanism.

[0046]The propulsion mechanism includes a drive worm 2 mounted on the drawer bottom plate 5 through the front support 1 and the rear support 4, the drive worm 2 can engage with the trough-shaped turbine block 10 installed on the cabinet layer 23, and relative to the trough-shaped The turbine block 10 moves to realize the linear motion of the drawer relative to the cabinet body.

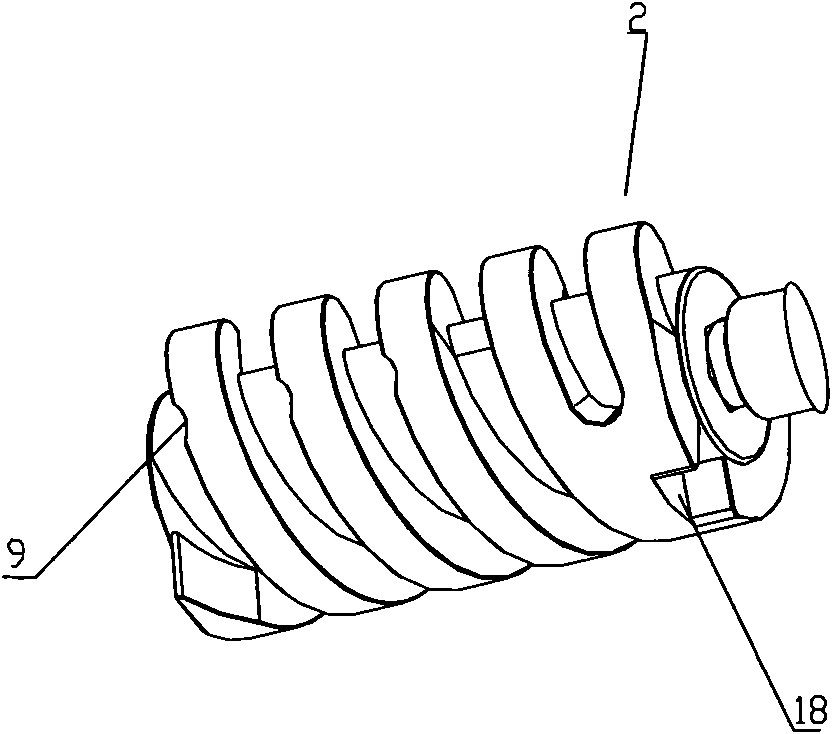

[0047] combine image 3 and Figure 4 As shown, the transmission worm 2 has a double-helix structure, which can reduce the number of rotations for adjusting the working position compared with the single-helix structure, and is easier to operate. Due to the large meshing angle between the transmission worm 2 and the trough-shaped turbine block 10, the transmission worm 2 is prone to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com