Electrode segmentation type single drive and two-way piezoelectric motor

A piezoelectric motor and electrode segmentation technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of limited application and bulky piezoelectric motor system , to achieve the effect of simple structure, reduced size and power consumption, and simple power drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

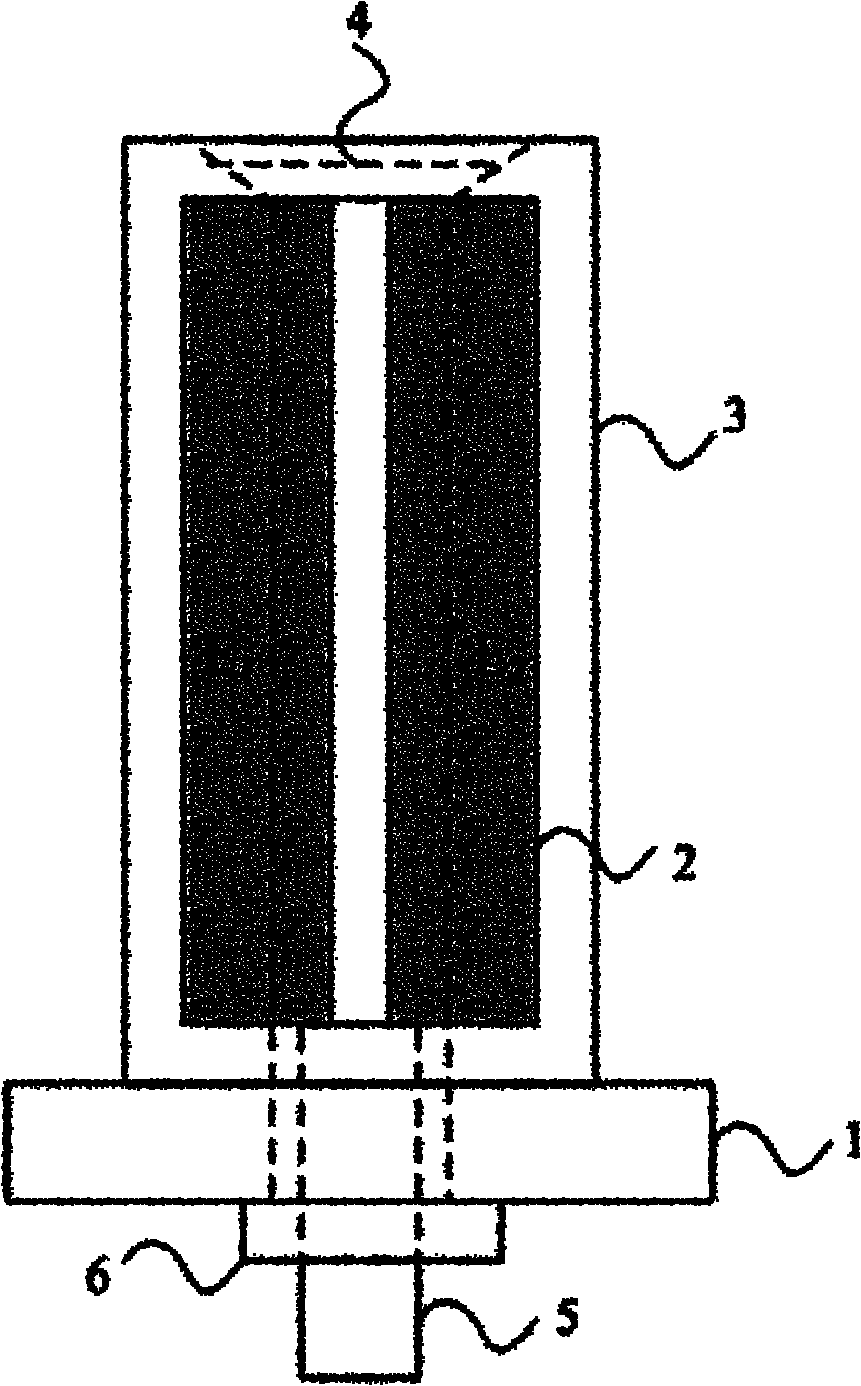

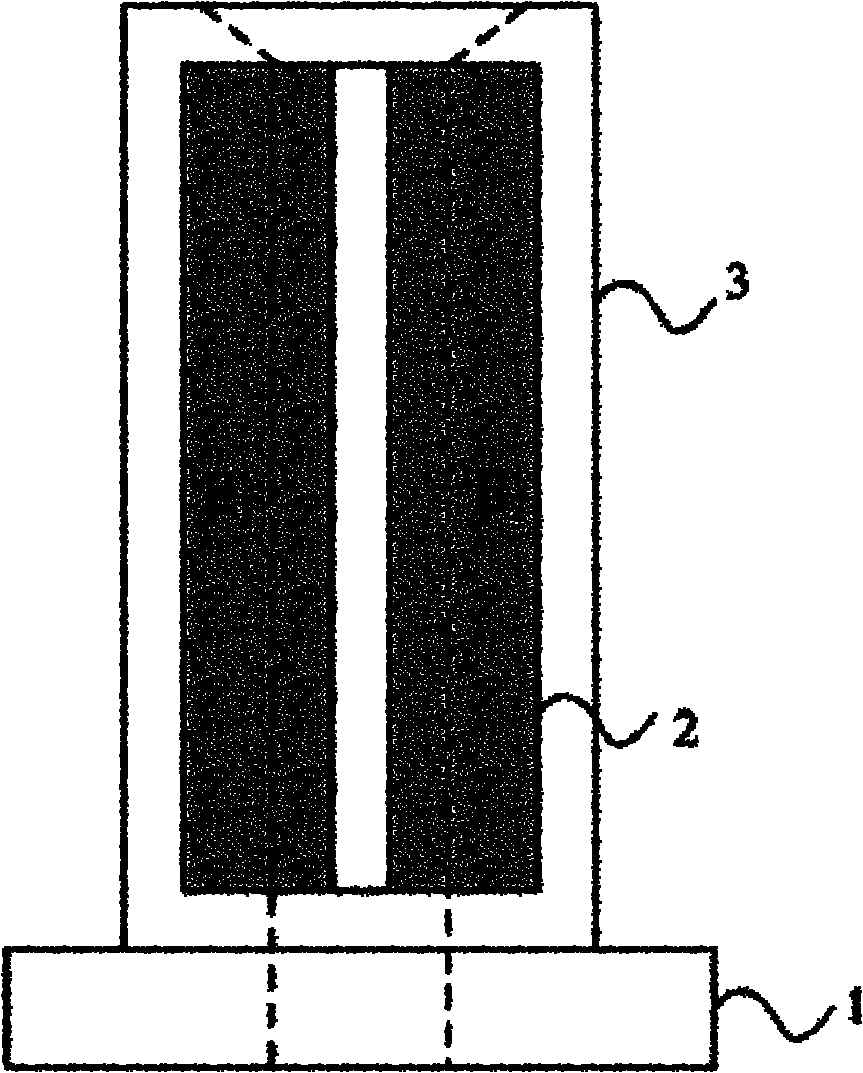

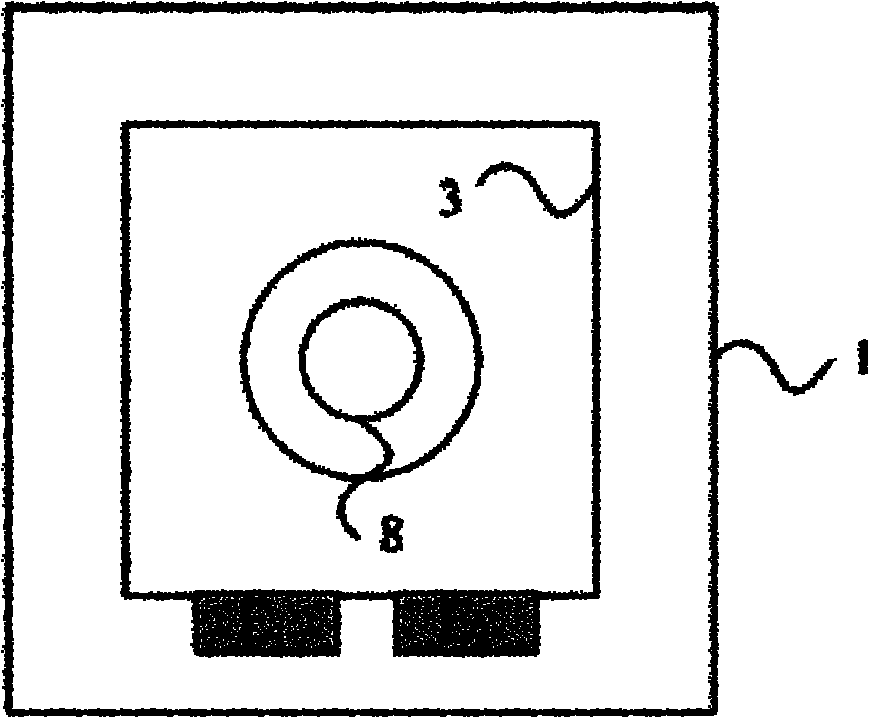

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the electrode split type single-drive bidirectional piezoelectric motor of the present invention includes a stator and a rotor that can rotate relative to the stator. The stator can be fixed by clamping or by the base 1 that is fixedly connected to the stator. The drive body 3 The central hole 8 runs through the base 1; the stator includes a driving body 3 with a central hole 8 and a piezoelectric sheet 2 bonded to the plane on one side of the driving body 3 by glue; the rotor includes a rotating body 5 passing through the central hole 8 of the driving body 3 And the cap body 4 that is fixedly connected with one end of the rotating body 5; the cap body 4 is in contact with the driving body 3, and there is a gap between the rotating body 5 and the center hole 8 of the driving body 3; the piezoelectric sheet 2 includes two mutually independent Piezoelectric sheet is piezoelectric sheet E 1 and piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com