Self-locking type invisible pulling head

An invisible slider and self-locking technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of inconvenient mechanized automatic assembly, small size, etc., to facilitate automatic assembly, reduce assembly procedures, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

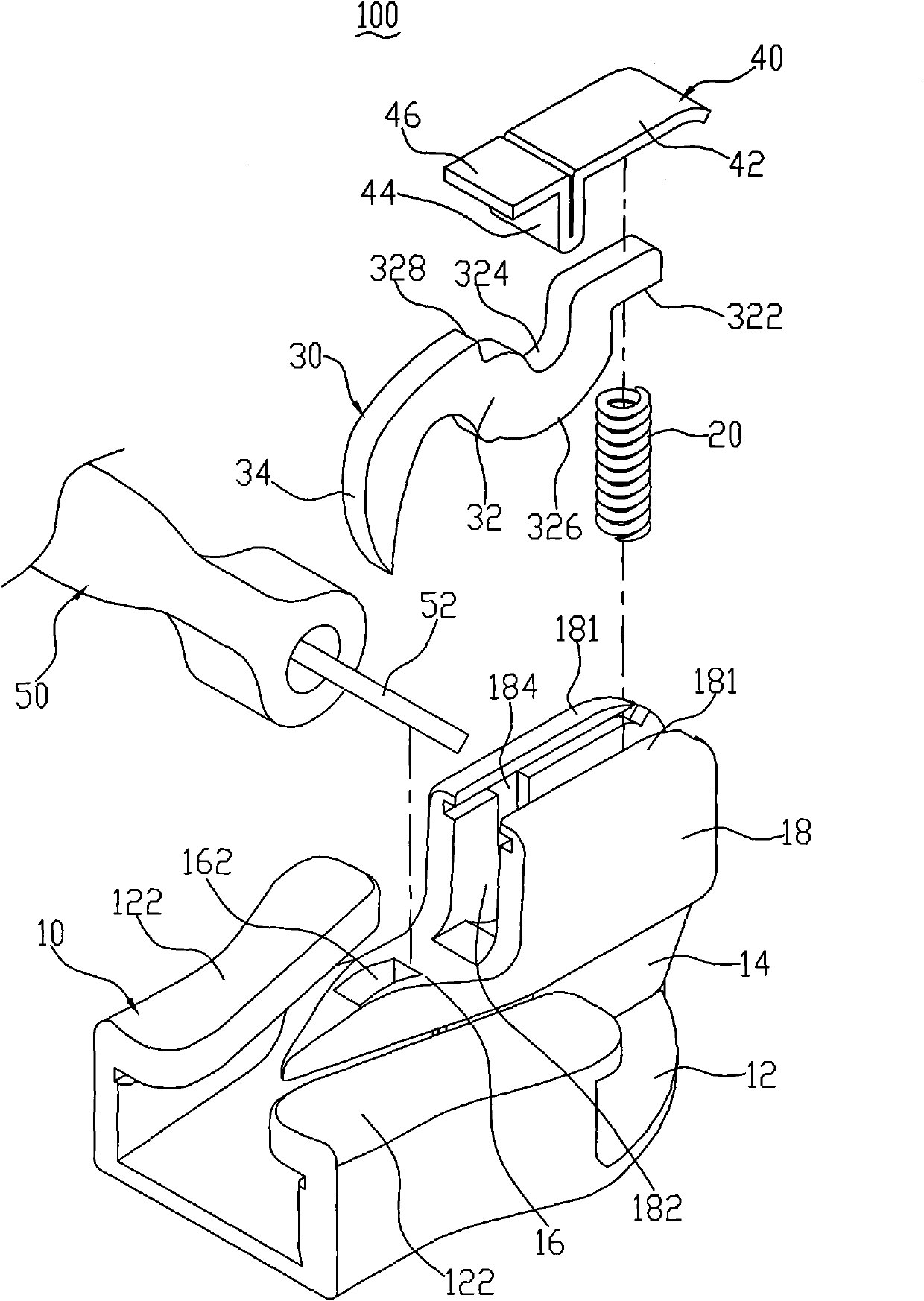

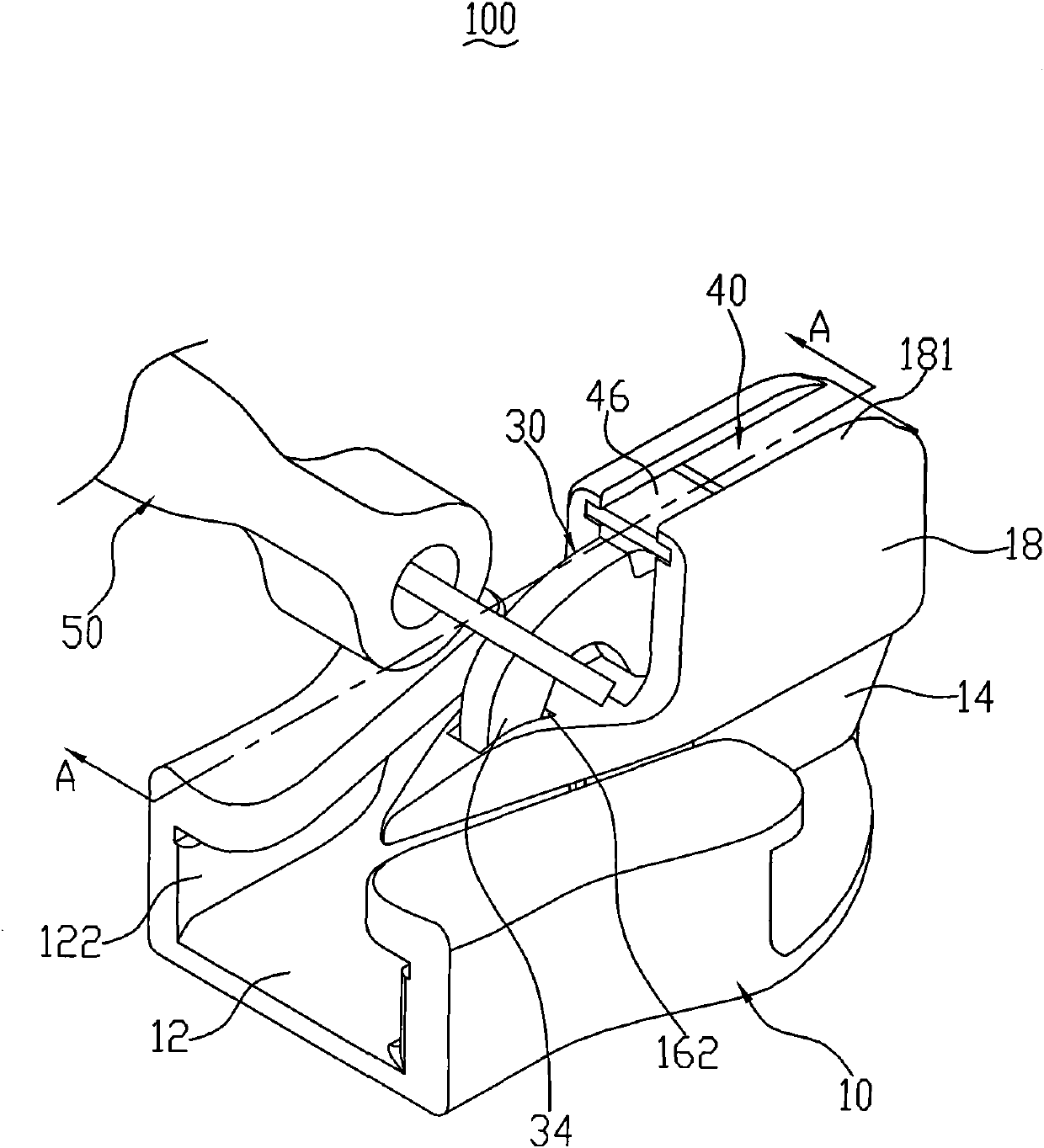

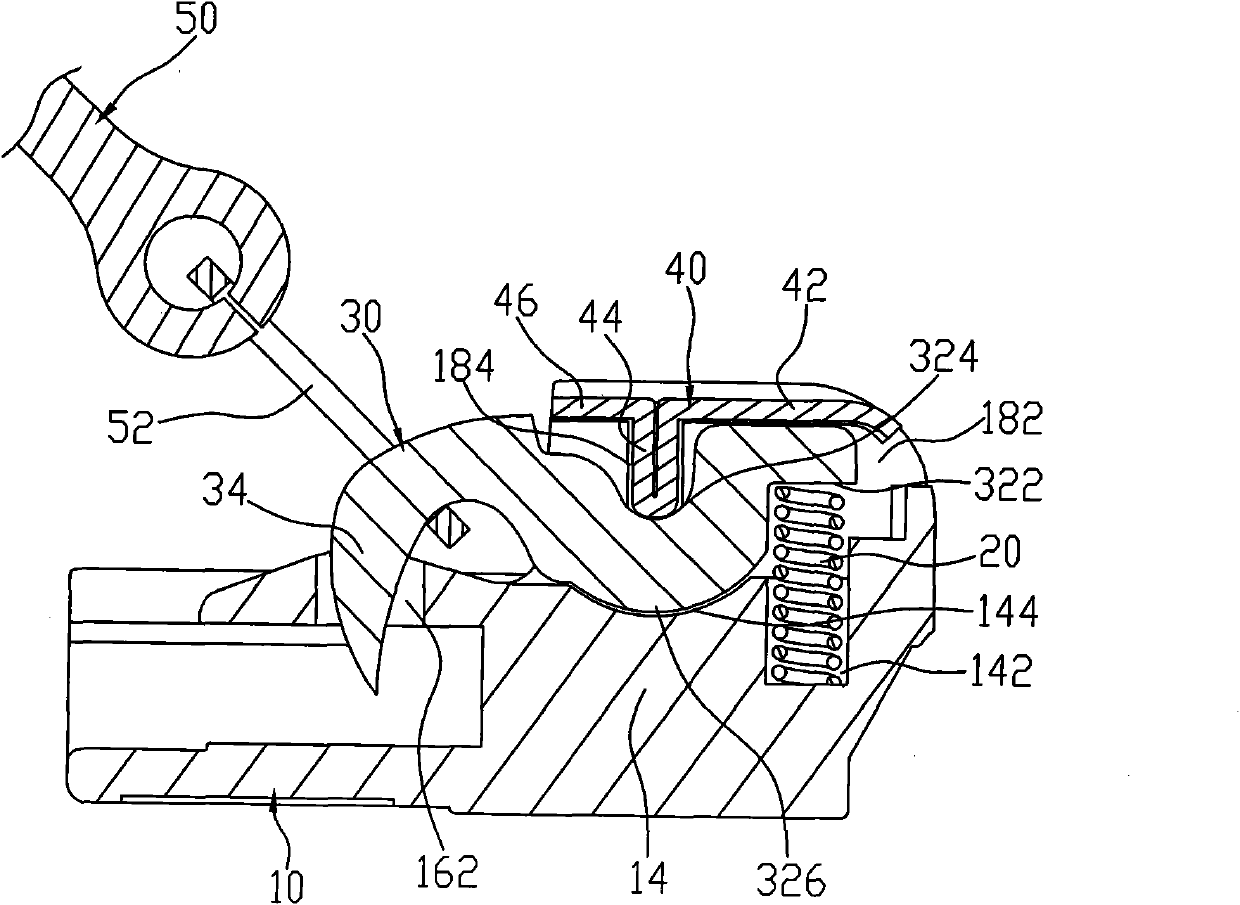

[0036] figure 1 It is a three-dimensional exploded view of the first embodiment of the invisible slider of the present invention. The invisible slider 100 includes a sliding block 10 , a spring 20 , a hook 30 , a pressed part 40 and a pull piece 50 . The spring 20, the horse hook 30, the pressed part 40 and the pull tab 50 are sequentially assembled on the slider 10 to form the invisible slider 100 (such as figure 2 shown). The slider 10 is integrally die-cast from zinc alloy.

[0037] Please refer to figure 1 and image 3 , the pressed part 40 is integrally formed by a rectangular metal sheet (not shown) through a cold stamping process. The pressed part 40 is roughly "T"-shaped in side view. The pressed part 40 includes two fixed sections 42, 46 and a pressed section 44. When forming, the metal sheet is first folded in half along a predetermined position, and then the two ends of the folded metal sheet are bent 90 degrees respectively, thereby forming the Two fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com