Long-acting ceftiofur hydrochloride injection and preparation method thereof

A technology of ceftiofur hydrochloride and injection, which is applied in the field of long-acting ceftiofur hydrochloride suspension injection and its preparation, can solve the problems of short action time and achieve the effects of improving fluidity, good fluidity, and eliminating half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

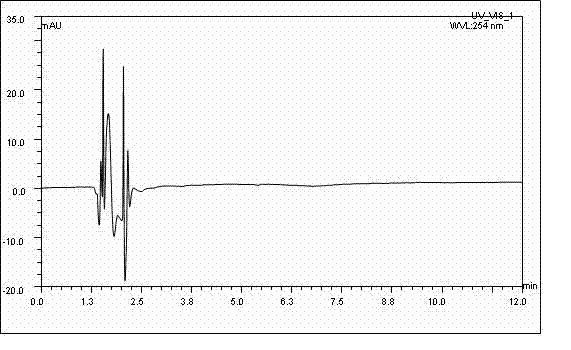

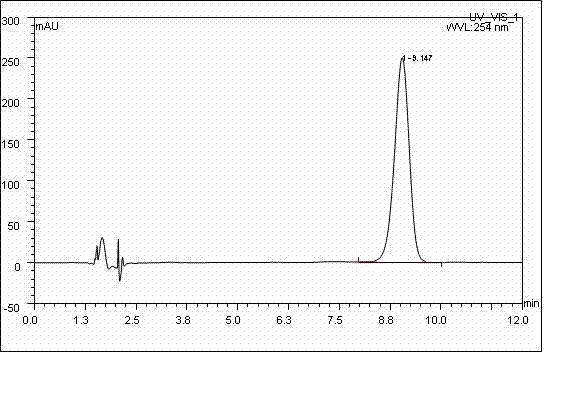

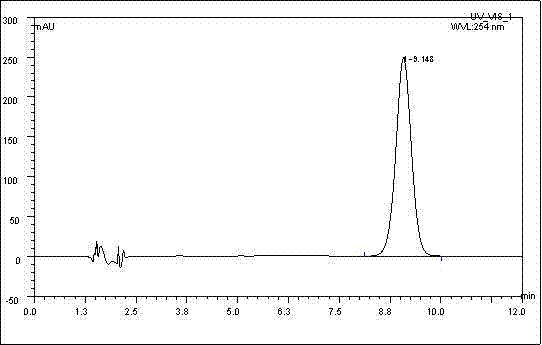

Image

Examples

Embodiment 1

[0027] (1) Add 7.5g of ceftiofur hydrochloride to 40ml of glycerol triacetate, stir magnetically, and mix well;

[0028] (2) Add 0.3g of compound suspending agent (hydrogenated castor oil: lecithin 1:2 (g / g) mixture) into glycerol triacetate at 90°C to dissolve;

[0029] (3) Cool the solution in step (2) to room temperature and add it to the stirring suspension in step (1), and stir evenly;

[0030] (4) Add 0.5g bacteriostatic agent chlorobutanol to the suspension in step (3), adjust to 100ml with the remaining triacetin, and stir thoroughly;

[0031] (5) Stir and mix for 30 minutes, pass through a high-speed shear disperser for 30 minutes at a speed of 1200r / min, pass through a colloid mill for 4 hours, and finally sterilize the sample by irradiating 60Co-γ rays at 3KGY to obtain a milky white or light yellow suspension .

[0032] The properties of the suspension are milky white or light yellow, the particle size distribution is uniform, the average particle size is 8.38 μm...

Embodiment 2

[0034] (1) Add 7.5g of ceftiofur hydrochloride to 40ml of composite solvent (36ml of glycerol triacetate and 4ml of polyethylene glycol 200), stir magnetically, and mix well;

[0035] (2) Add 0.3g of compound suspending agent (hydrogenated castor oil: lecithin 1:2 (g / g) mixture) into glycerol triacetate at 90°C to dissolve;

[0036] (3) Cool the solution in step (2) to room temperature and add it to the stirring suspension in step (1), and stir evenly;

[0037] (4) Add 0.2g of bacteriostatic agent benzyl alcohol to the suspension in step (3), adjust to 100ml with the remaining triacetin, and stir thoroughly;

[0038] (5) Stir and mix for 30 minutes, pass through a high-speed shear disperser for 30 minutes at a speed of 1200r / min, pass through a colloid mill for 4 hours, and finally sterilize the sample by irradiating 60Co-γ rays at 3KGY to obtain a milky white or light yellow suspension .

[0039] The properties of the suspension are milky white or light yellow, the particle...

Embodiment 3

[0041] (1) Add 7.5g of ceftiofur hydrochloride to 40ml of compound solvent (36ml of glycerol triacetate and 4ml of polyethylene glycol 200: Span 80 at a ratio of 2:1 (v / v) mixture), stir magnetically, and mix well ;

[0042](2) Add 0.3g of compound suspending agent (hydrogenated castor oil: lecithin 1:2 (g / g) mixture) into glycerol triacetate at 90°C to dissolve;

[0043] (3) Cool the solution in step (2) to room temperature and add it to the stirring suspension in step (1), and stir evenly;

[0044] (4) Add 0.5g of bacteriostatic agent benzyl alcohol to the suspension in step (3), adjust to 100ml with the remaining triacetin, and stir thoroughly;

[0045] (5) Stir and mix for 30 minutes, pass through a high-speed shear disperser for 30 minutes at a speed of 1200r / min, pass through a colloid mill for 4 hours, and finally sterilize the sample by irradiating 60Co-γ rays at 3KGY to obtain a milky white or light yellow suspension .

[0046] The properties of the suspension are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com