Recessed type tube head automatic welding machine

An automatic welding machine, retractable technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of difficult operation, difficult to obtain continuous and uniform welds, low efficiency, etc., to expand welding range, increased stability, and effects of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described in conjunction with the following examples.

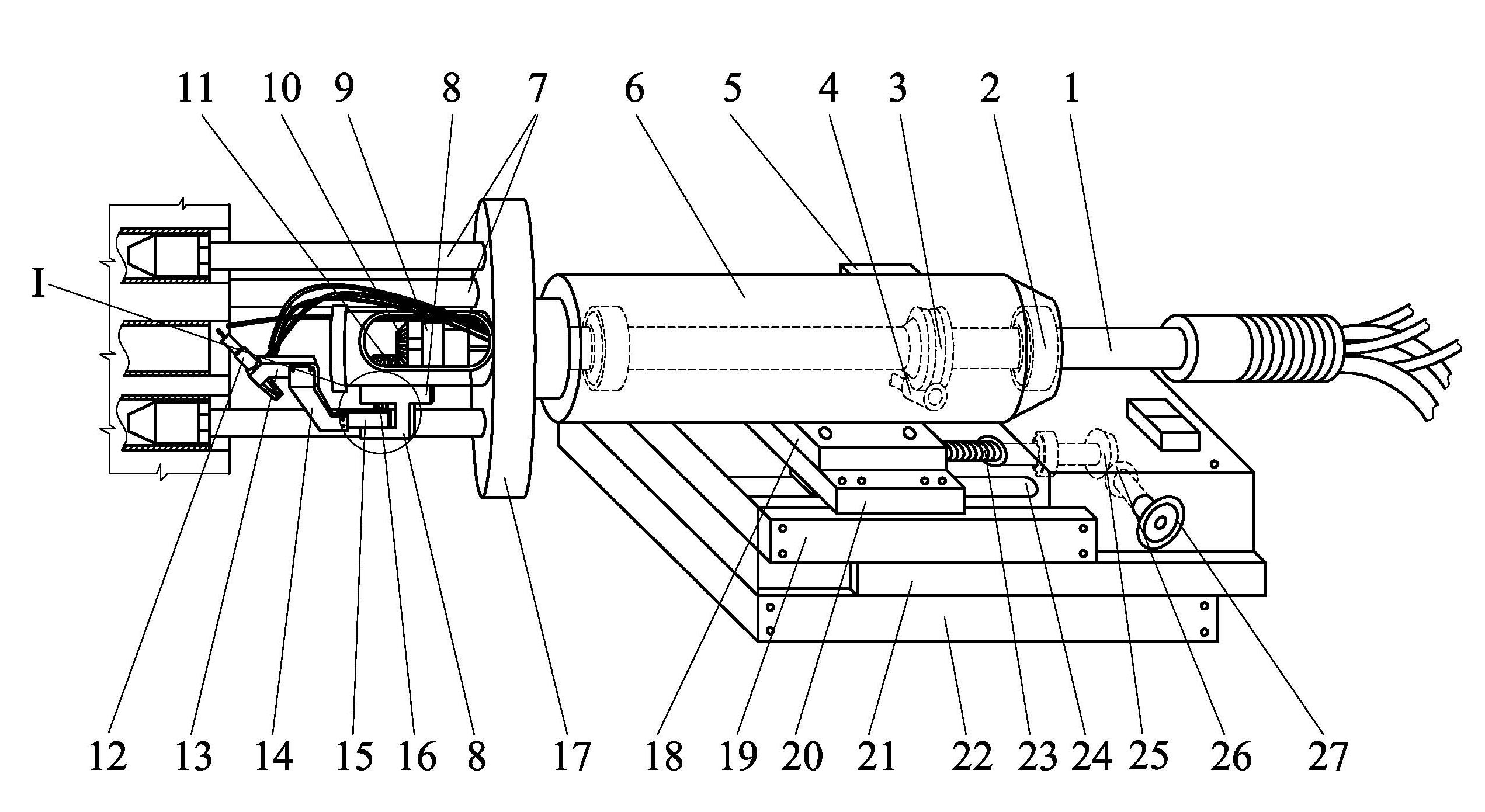

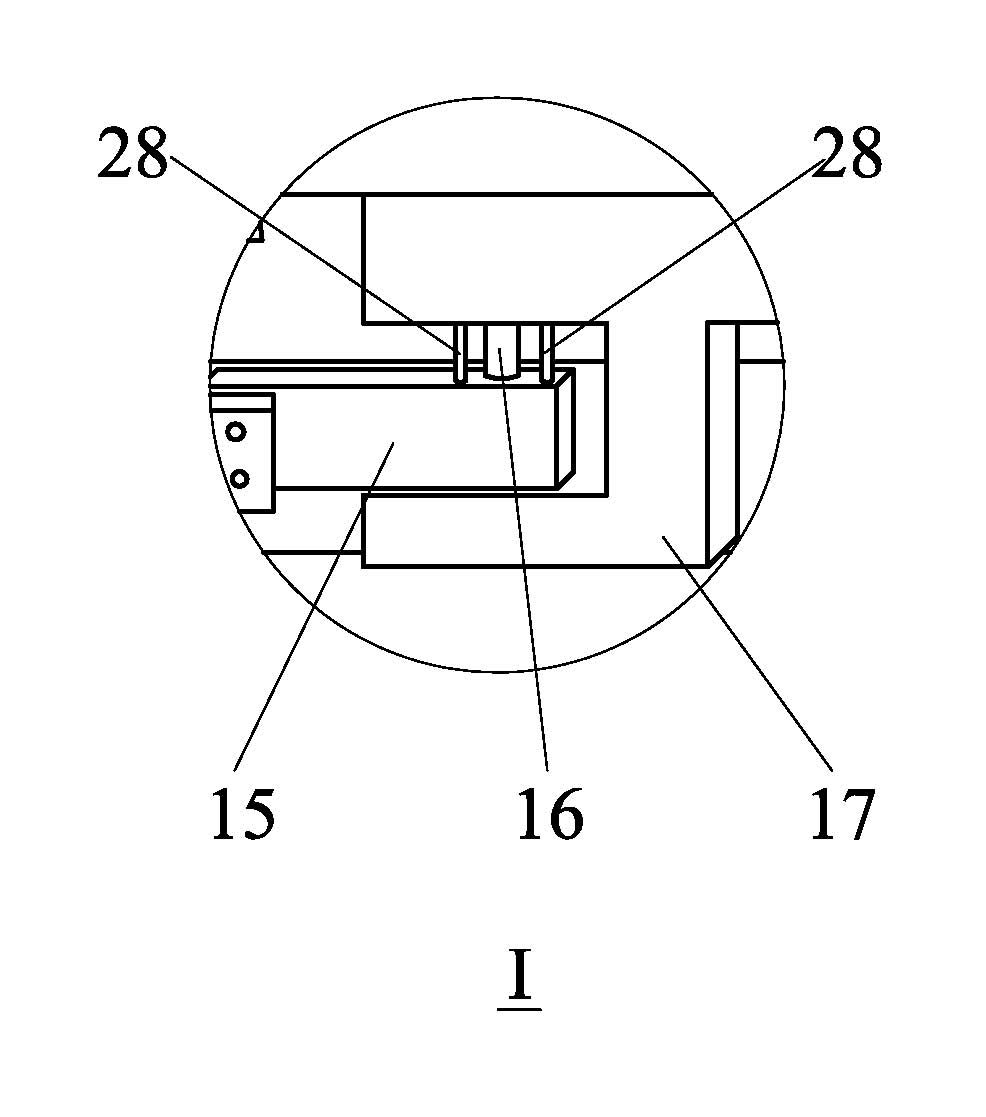

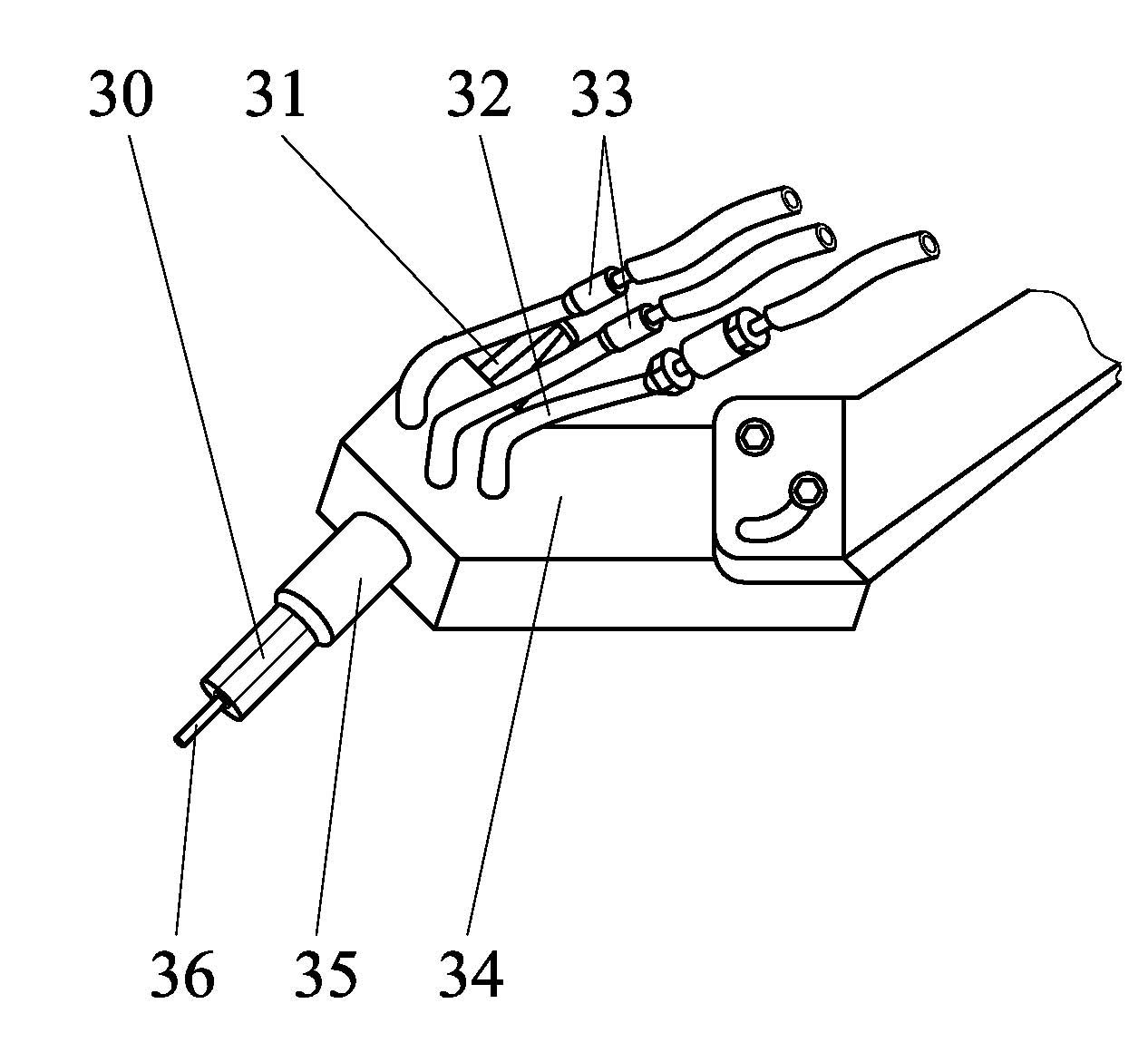

[0034] A specific embodiment of a retractable pipe head automatic welding machine of the present invention, as figure 1 As shown, it includes a rotating main shaft 1, a body 6, a welding torch 12 and a welding torch connecting plate 17. The rotating main shaft 1 penetrates the body 6 and is assembled in the body 6 through a bearing 2. The welding torch connecting plate 17 is connected and arranged on the edge of the body 6. Axial front side (refer to figure 1 , should be the left side of the machine body 6 in the figure), the welding torch 12 is arranged on the welding torch connecting plate 17, wherein a rotating spindle driving device 5 is provided, and the rotating spindle driving device 5 includes a driving motor and a worm gear connected to the driving motor transmission mechanism. Wherein, the worm gear transmission mechanism includes a worm wheel 3 and a worm screw 4, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com