Folding worktable

A workbench and countertop technology, applied in workbenches, manufacturing tools, etc., can solve the problems of large storage space and inconvenient splicing, and achieve the effect of convenient folding and splicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

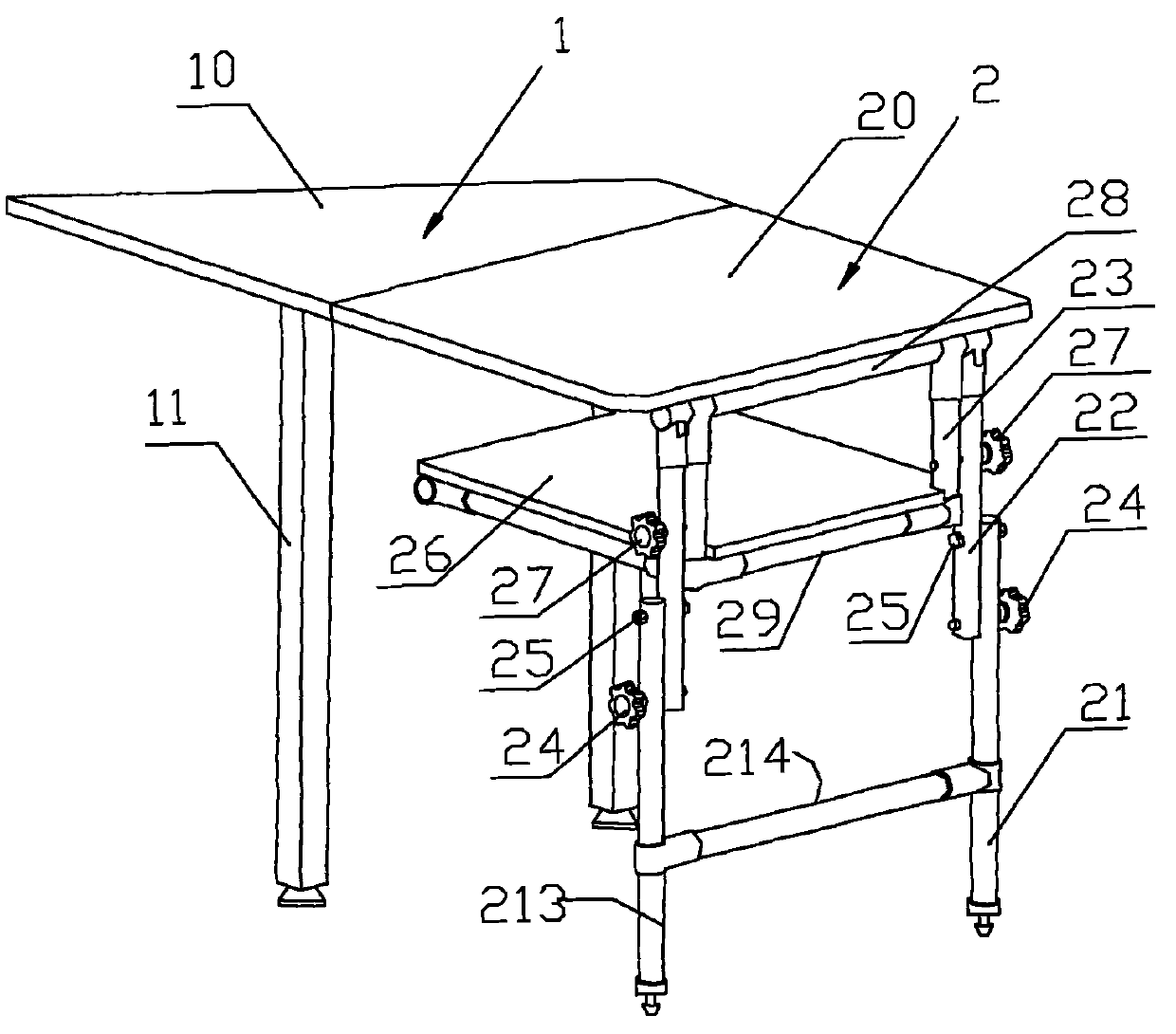

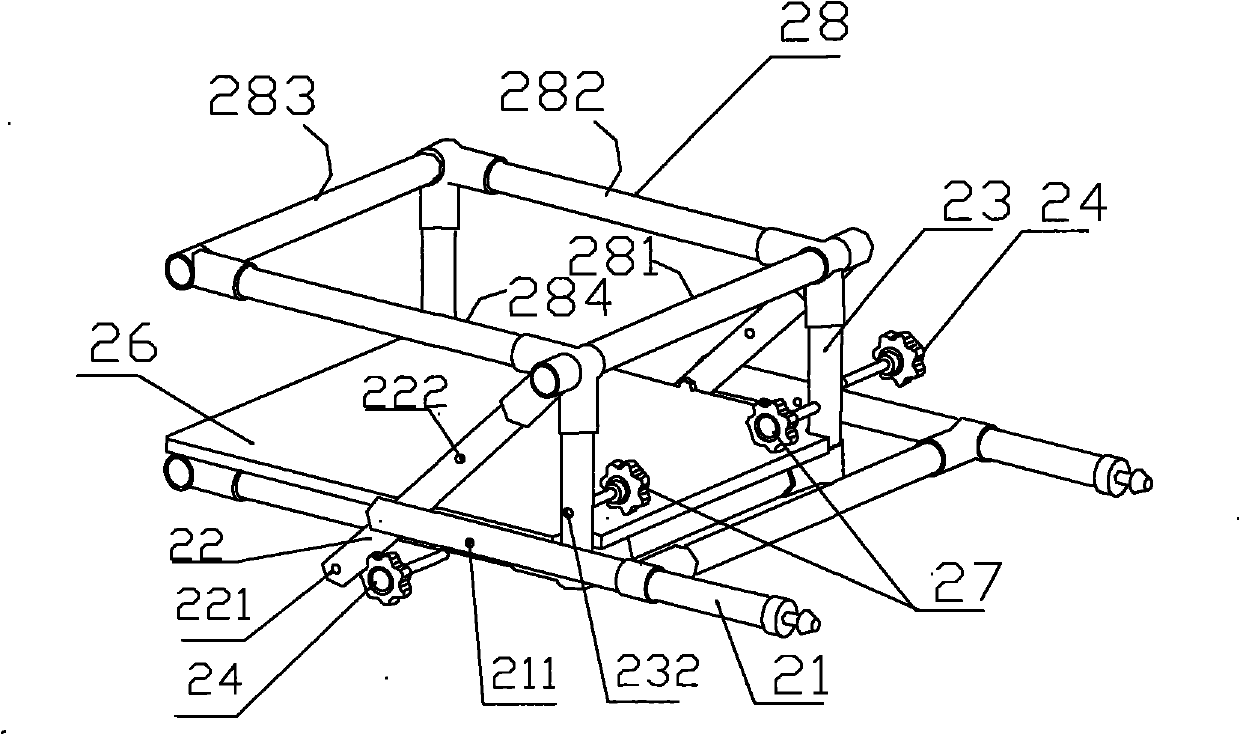

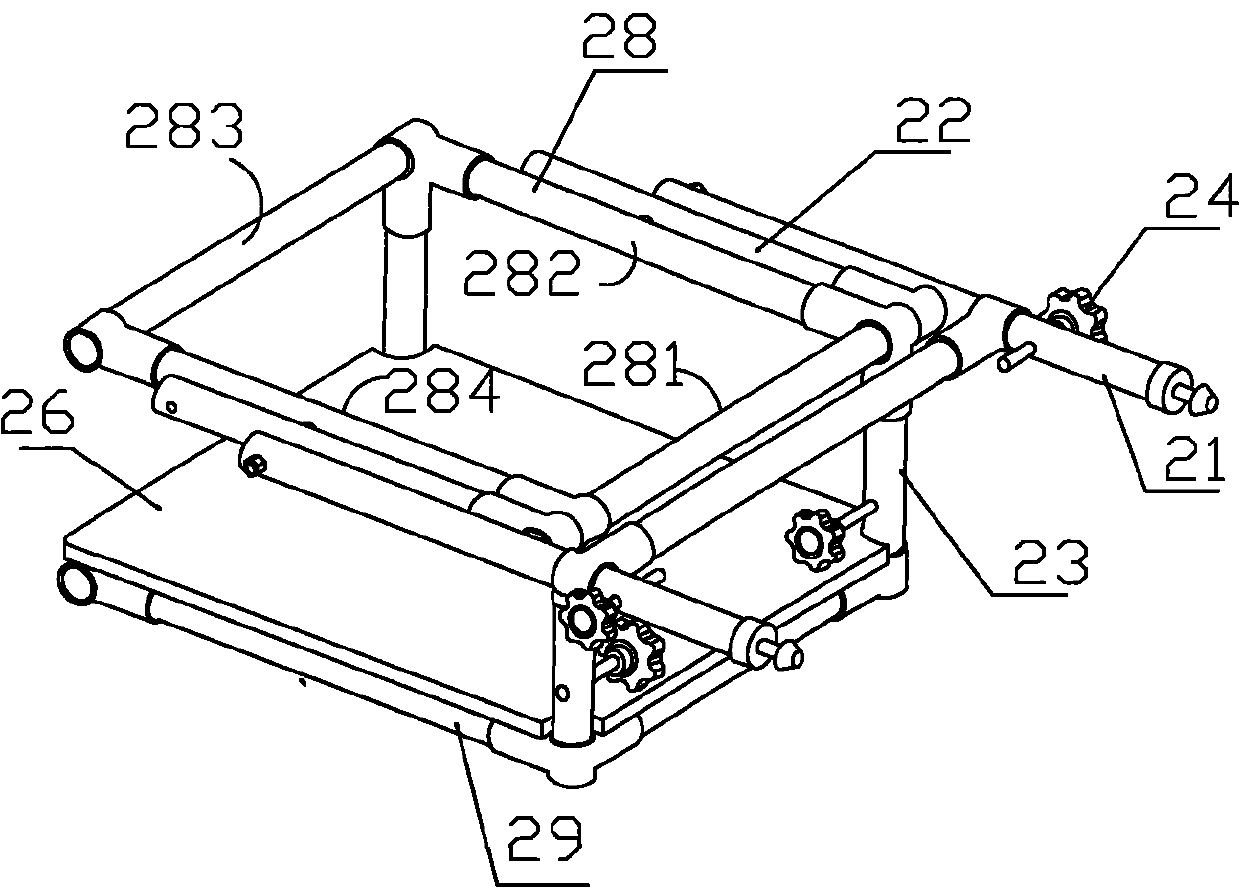

[0020] refer to Figure 1-4 ,Such as figure 1 Shown is the structural representation of folding workbench of the present invention; Figure 2A , Figure 2B is a schematic diagram of the folding process of the folding workbench of the present invention; image 3 It is a schematic diagram of the folded structure of the folding workbench of the present invention. The folding workbench of the present invention includes: an assembly line workbench 1 and a foldable folding table 2 connected to the side of the assembly line workbench 1 .

[0021] refer to figure 1 and image 3 , the assembly line workbench 1 includes a panel 10 and a foot 11 installed below the panel 10 , the foot 11 is supported on a laying surface (for example: on the ground), and the panel 10 is placed above the foot 11 . The folding table 2 includes a table top 20 and a bracket unit. The improvement of the present invention is that the folding table 2 has two states: a use state and a folded state, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap