Method and device for controlling over-relaxation of wire rope in floating of winch

A technology of steel wire rope and coil control, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of excessive wear and tear of steel wire ropes, loose strands of reels, chaotic winding of drums, and damaged steel wire ropes, so as to prevent damage to steel wire ropes, reduce labor intensity, Avoid the effect of abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

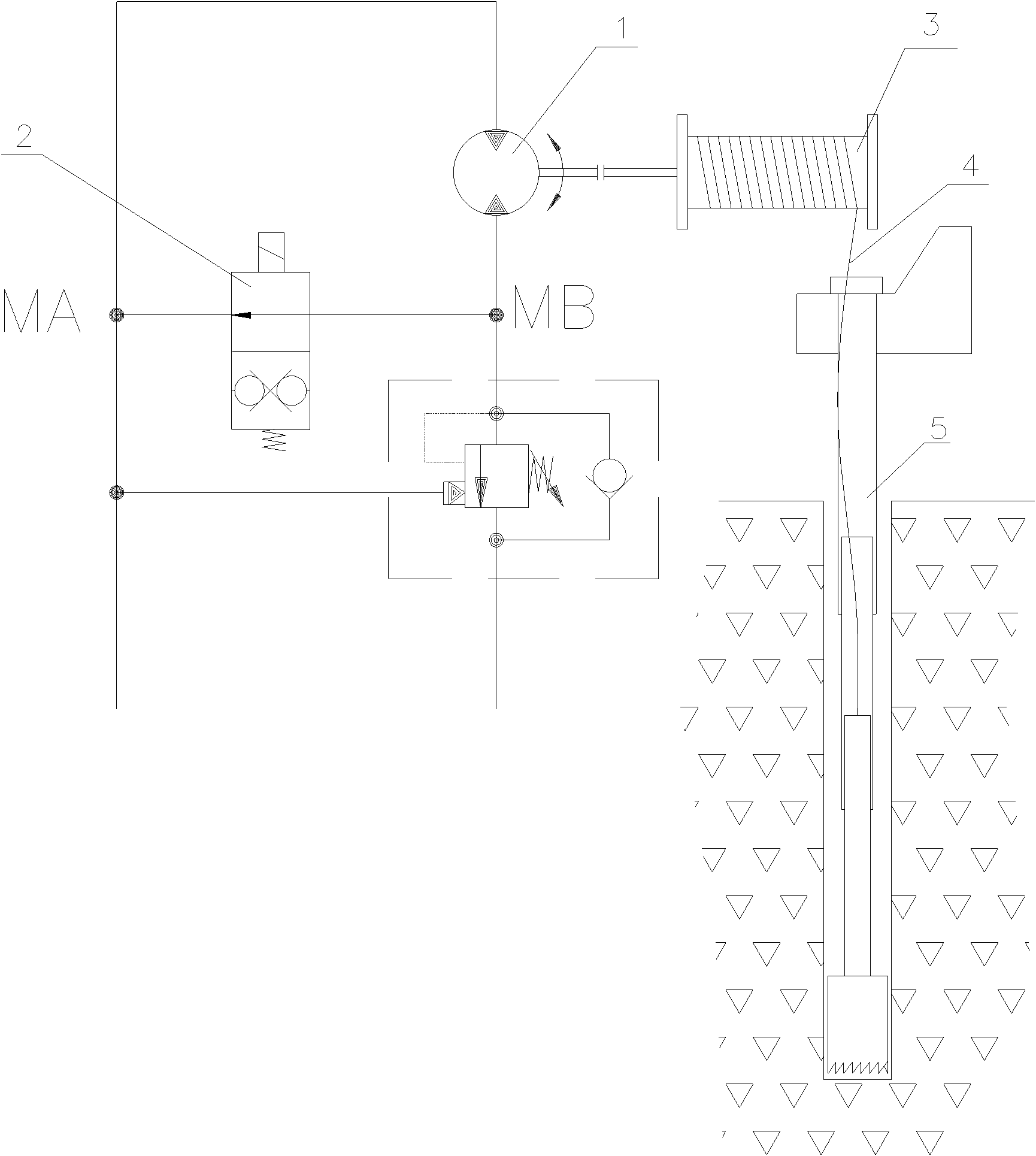

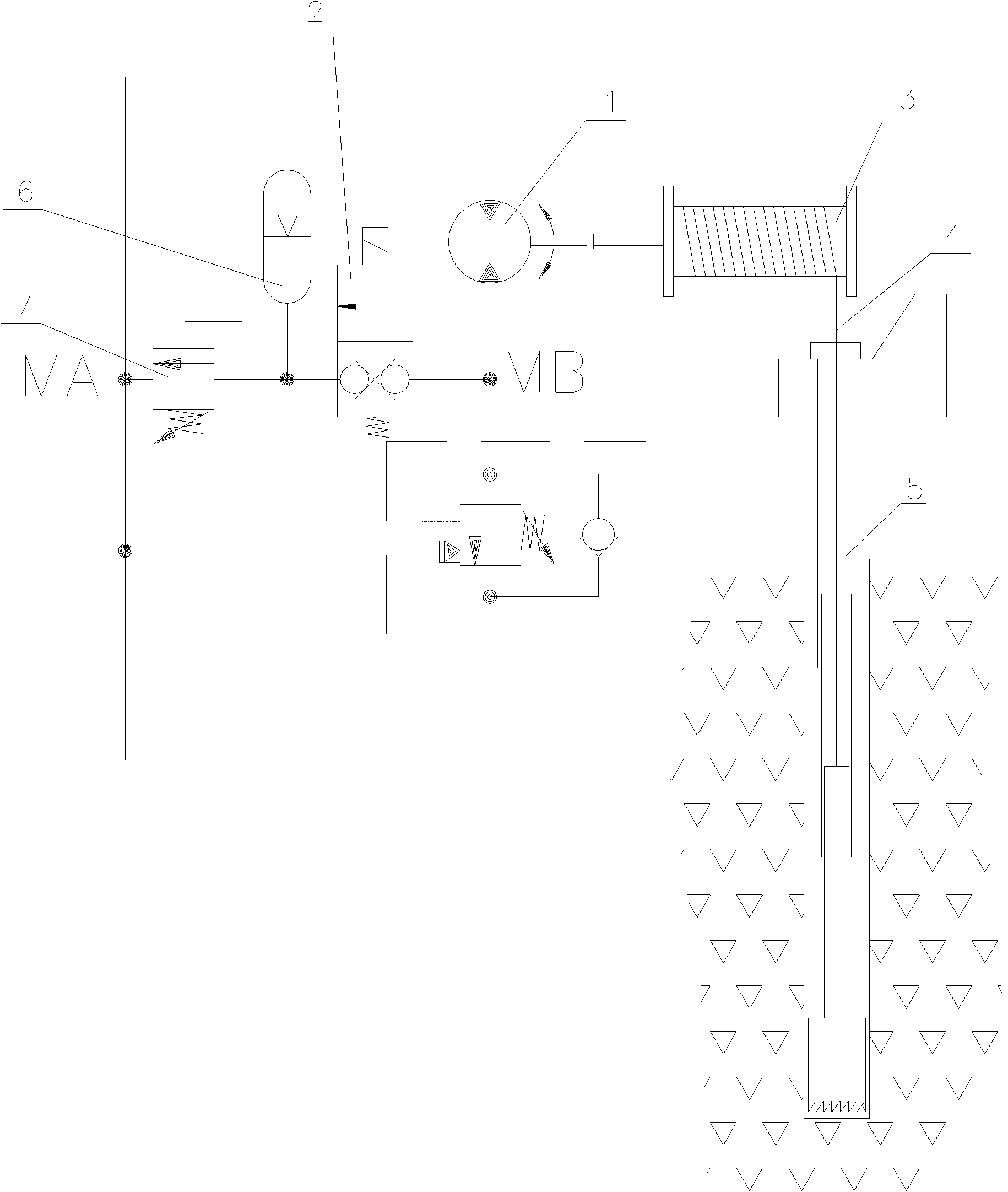

[0014] A method for controlling the over-releasing of the wire rope when the rotary drilling rig is hoisted and floated. During the process of floating and lowering by the weight of the load, the wire rope is always in a pre-tightened state by giving a certain back pressure to the lifting side of the hoist. When the hoist is driven by a motor, when the self-weight is lowered, a certain reverse voltage is given to the motor, so that the hoist can only tension the wire rope, but cannot overcome the force of the drilling tool's self-weight drop. When the winch is driven by the hydraulic oil circuit, when the self-weight is lowered, a back pressure valve and an accumulator are added to the floating control oil circuit, so that the wire rope is tensioned when the winch is in a floating state, and the drilling tool can rely on its own weight. Drill h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com