Novel efficient diving sewage pump

A sewage pump, high-efficiency technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of increasing pump hydraulic loss, equipment failure, turbulence and impact, etc., to reduce hydraulic loss, improve efficiency, reduce turbulence The effect of flow and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] specific implementation plan

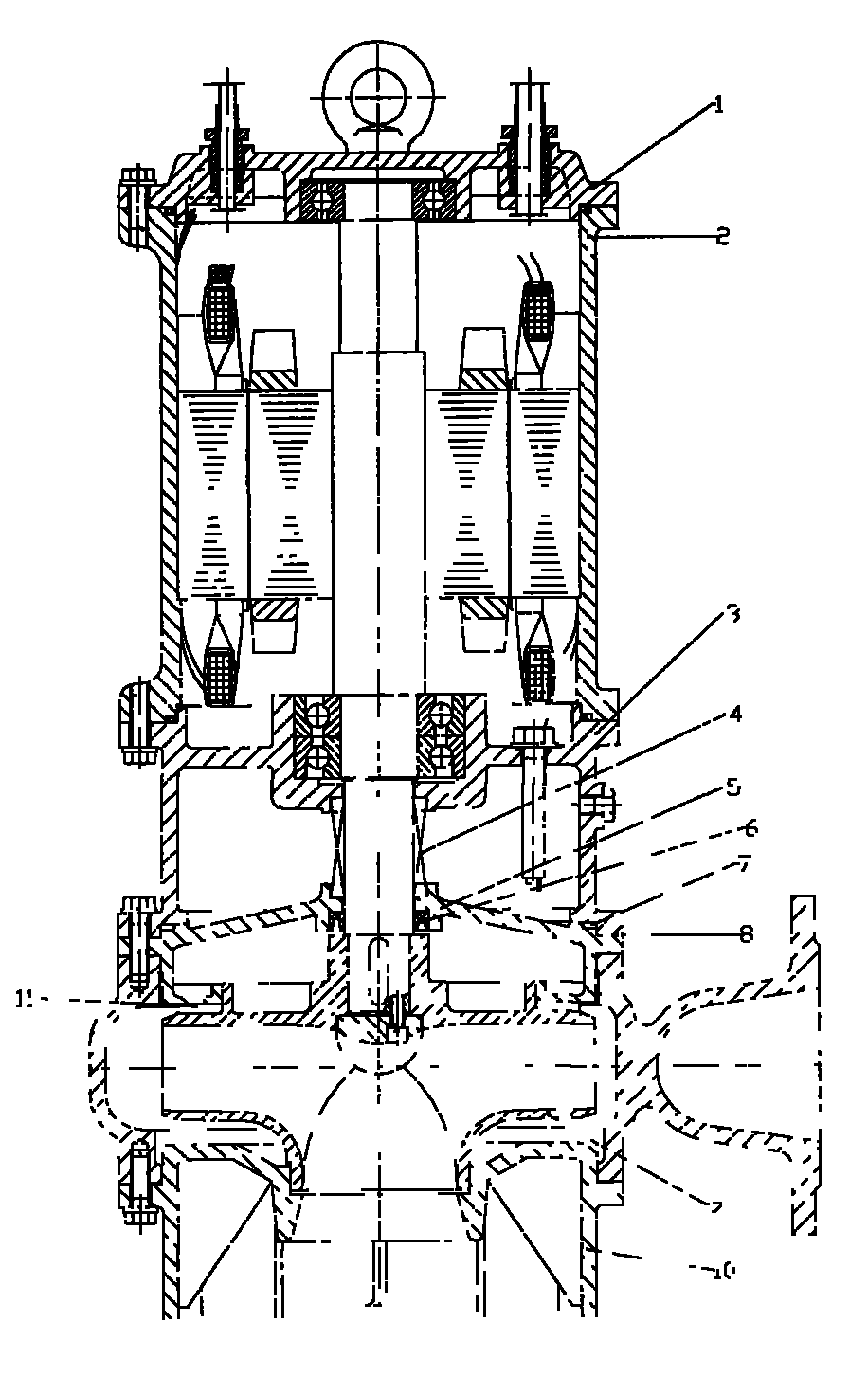

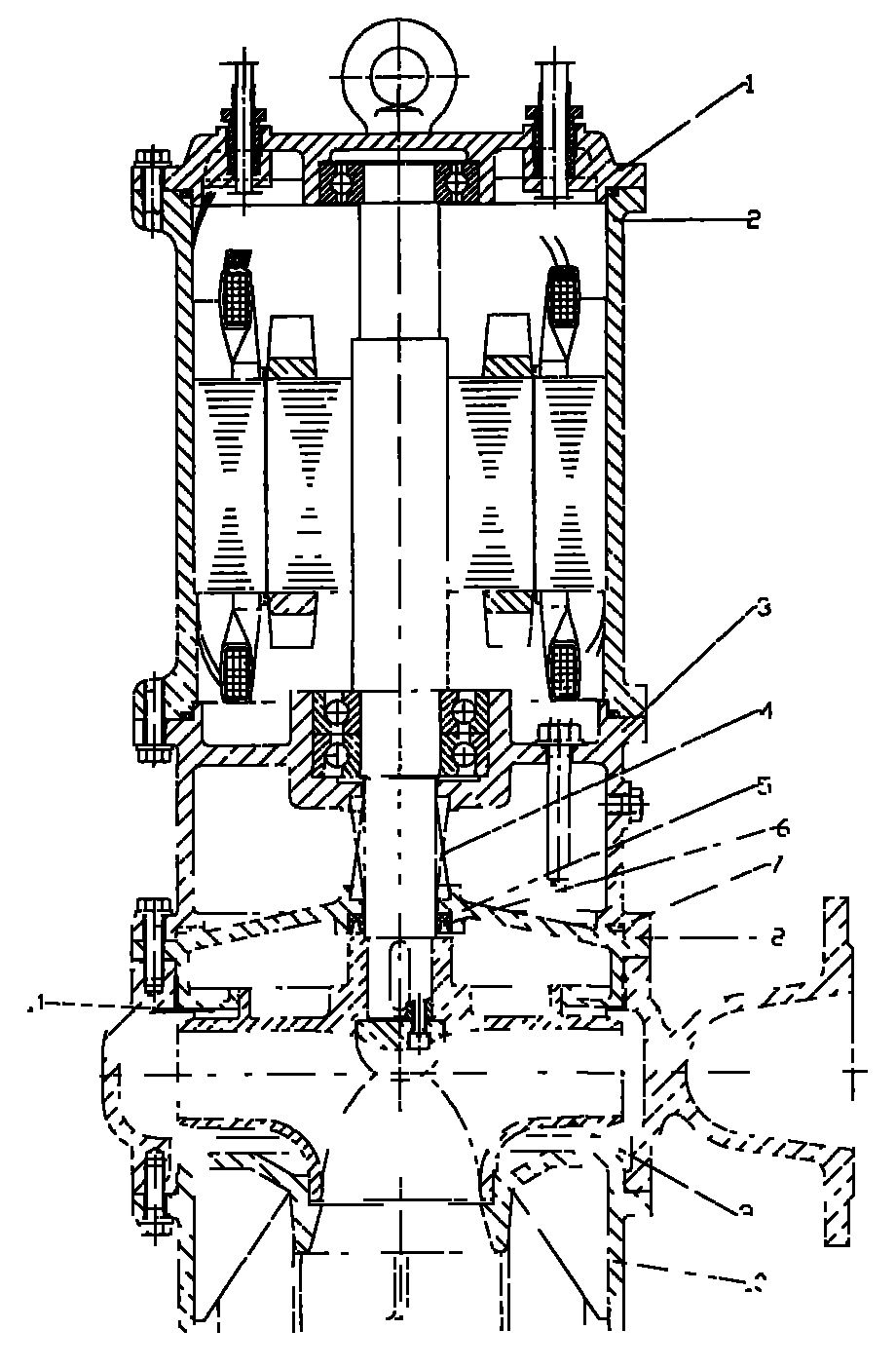

[0006] Attached blades 11 are arranged above the impeller, and a sealing surface is formed between the impeller attached blades 11 and the pump cover, which reduces the pressure between the pump cover and the pump body, the cavity and the oil seal, and ensures reliable sealing of the oil chamber. At the same time, it reduces the turbulent flow and impact generated by the liquid in the flow part of the pump body, thereby reducing the hydraulic loss of the pump and improving the working efficiency and stability of the pump.

Description of drawings

[0007] figure 1 It is a schematic diagram of the overall structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com