Method for reducing vibration and noise of permanent-magnet motor

A permanent magnet motor, noise technology, applied in the direction of torque ripple control, etc., can solve the problem that the unit shape optimization method does not establish a general priority criterion for the magnetic pole shape, the lack of an optimal segment angle, and the non-uniform distribution of the magnetic pole. Pole inclination, unit number optimization method does not give the slot/pole/phase number matching principle, etc., to achieve the effect of convenient parameter selection, vibration reduction and/or noise reduction, and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

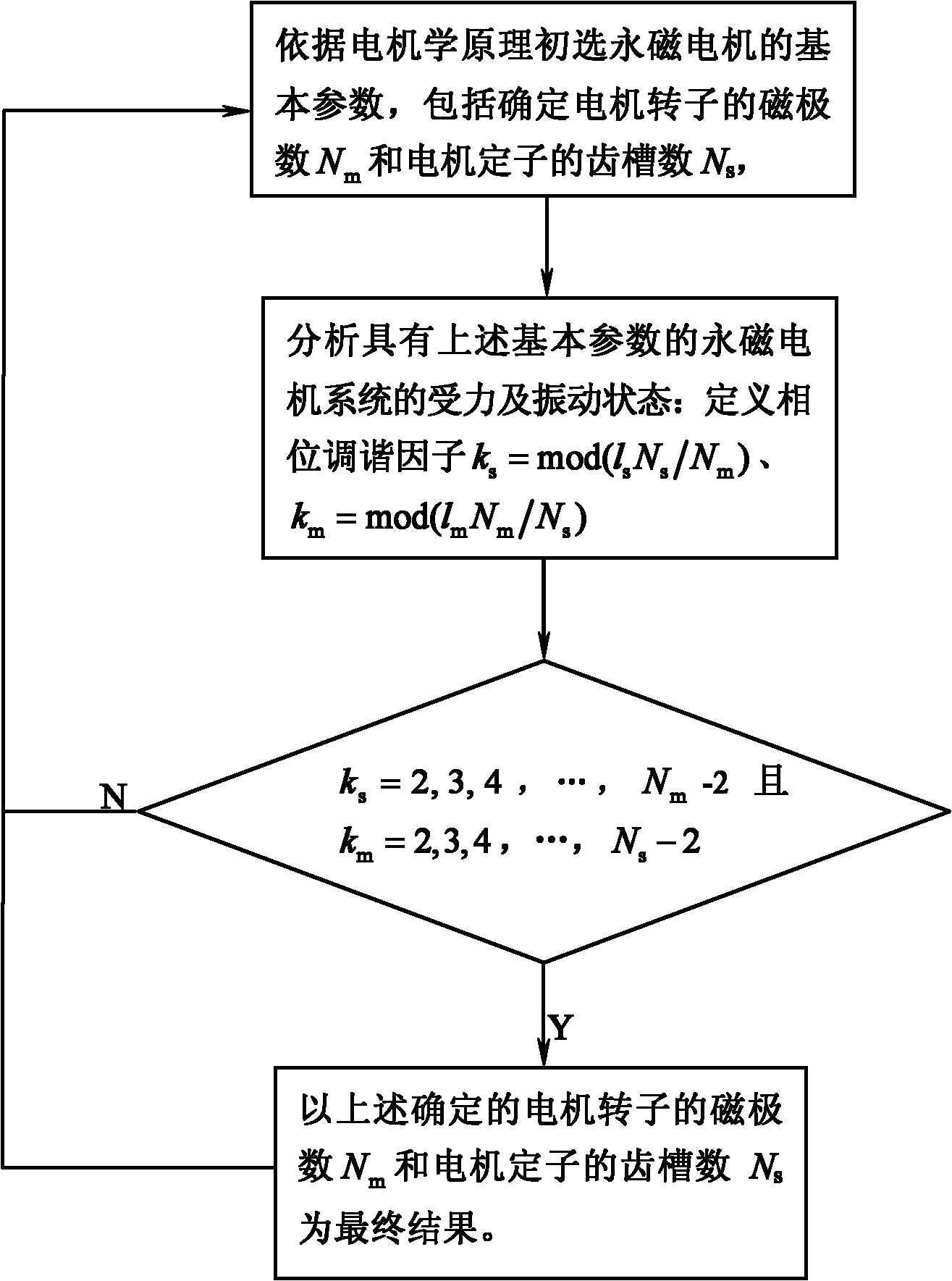

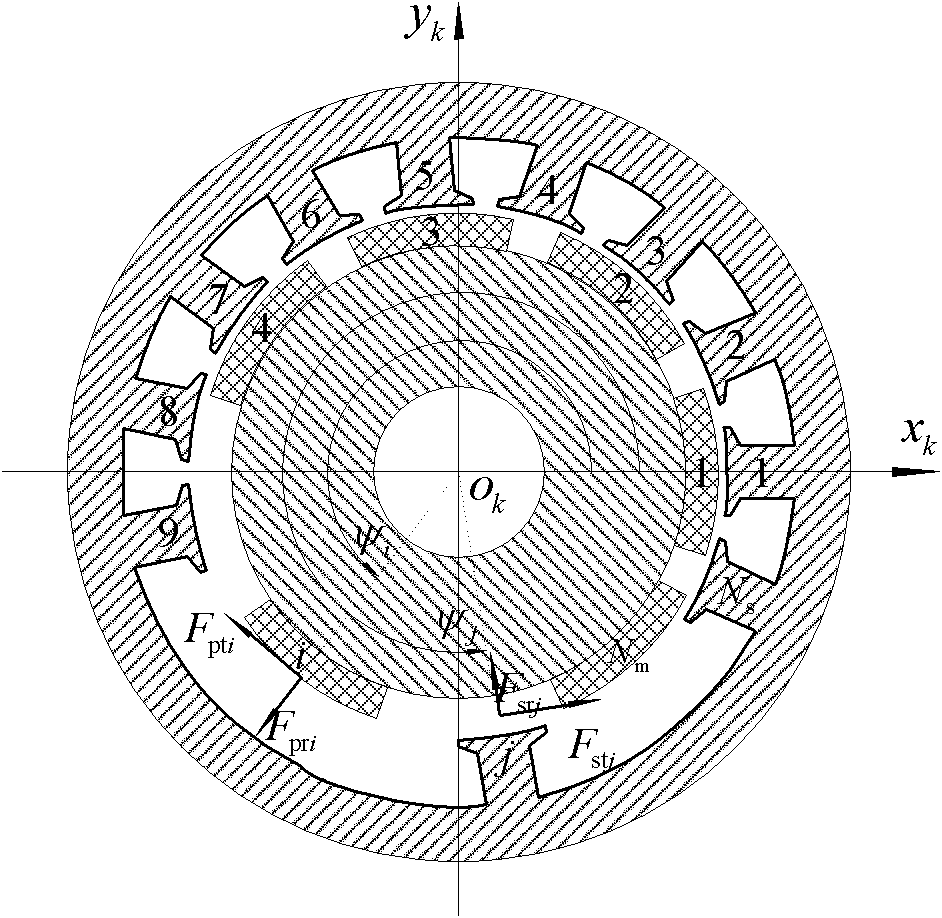

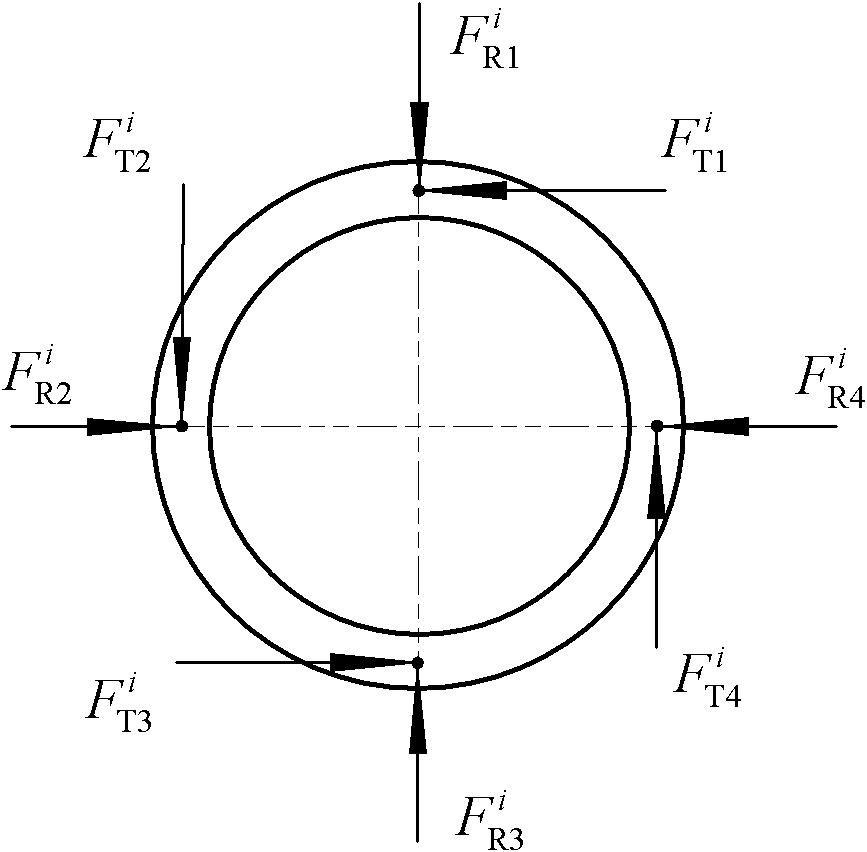

[0045] Such as figure 1 The shown method of the present invention for reducing the vibration and noise of the permanent magnet motor comprises the following steps: (1) according to the primary selection of the number of magnetic poles and the number of slots in the application; (2) judging the force and vibration of the permanent magnet motor State: if according to the formula k s =mod(l s N s / N m ) to get the phase tuning factor k s =0 and according to the formula k m =mod(l m N m / N s ) to obtain k m = 0, the permanent magnet motor will produce torque ripple; if the phase tuning factor k s = 1 or N m -1,k m = 1 or N s -1, permanent magnet motor will produce unbalanced magnetic pull; if k s =2,3,4,...,N m -2, and k m =2,3,4,...,N s -2, the permanent magnet motor will be in a state of force balance, where N m is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com