Method for manufacturing circuit board, circuit board and chip packaging structure

A manufacturing method and chip packaging technology, which are applied to circuits, printed circuit components, secondary processing of printed circuits, etc., can solve the problem of reducing the wiring area of the double-layer circuit board 100, and the wiring density of the double-layer circuit board 100 cannot be improved or reduced. Double-layer circuit board 100 wiring flexibility and other issues to achieve the effect of improving wiring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

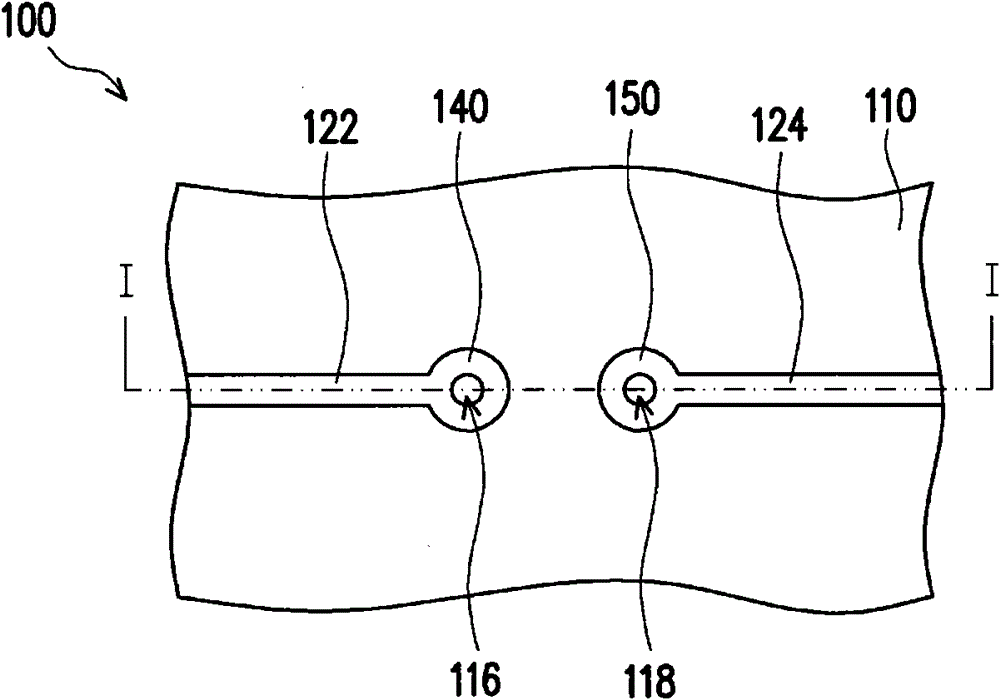

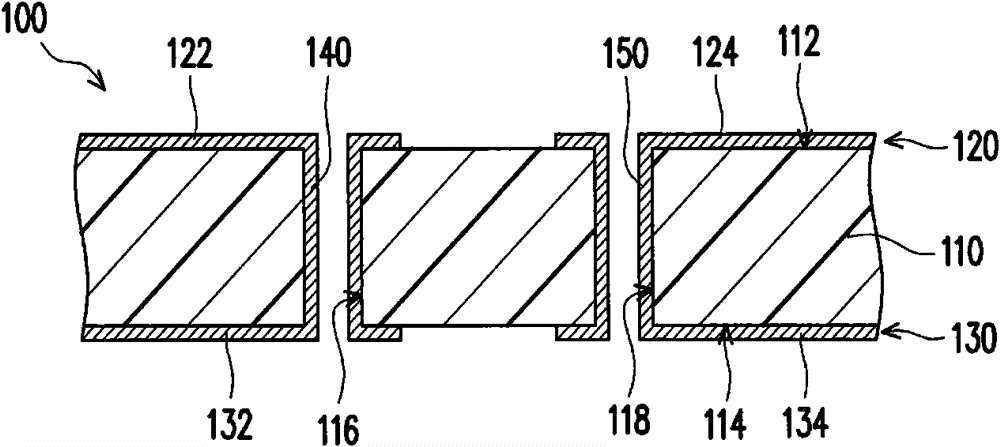

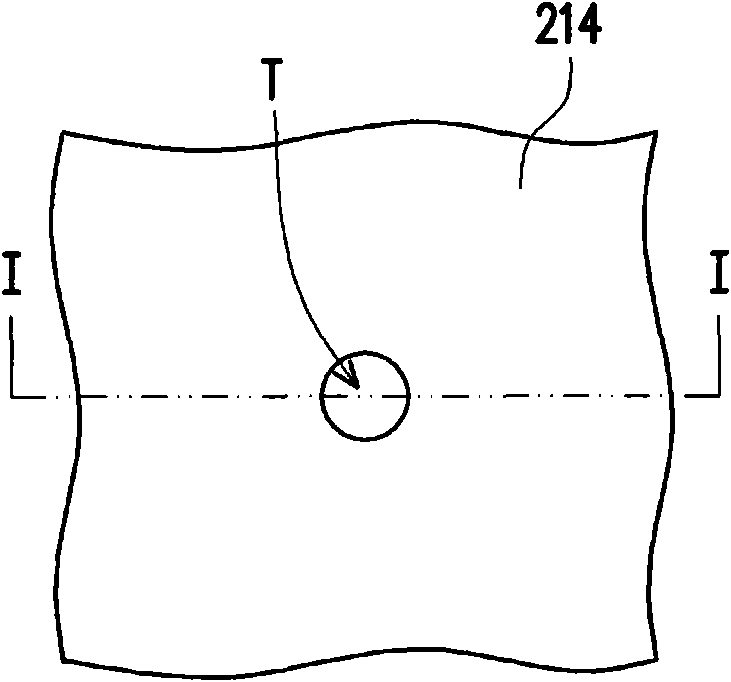

[0045] Figure 2A to Figure 2GIt is a top view of the manufacturing process of the circuit board according to an embodiment of the present invention. Figure 3A to Figure 3G respectively Figure 2A to Figure 2G The sectional view along the I-I line. Figure 4A to Figure 4E respectively Figure 2C to Figure 2G The sectional view along the line II-II. Figure 5A to Figure 5D respectively Figure 2D to Figure 2G Bottom view of the manufacturing process. It is worth noting that, Figure 2F only Figure 4C The top view of the middle area A, Figure 2G only Figure 4D Top view of middle area A.

[0046] Please refer to Figure 2A and Figure 3A , Firstly, a substrate 210 (such as a copper foil substrate) is provided, and the substrate 210 has a through hole T. In detail, the substrate 210 includes an insulating layer 212 , a first metal layer 214 and a second metal layer 216 , wherein the insulating layer 212 has a first surface 212 a and a second surface 212 b opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com