Polyester-imide precursor and polyester-imide

A technology of polyesterimide and polyesterimide layer, which is applied in the field of polyesterimide precursor and polyesterimide, can solve the problems of the reduction of mechanical properties of polyimide film, and achieve high tearing cracking strength, low hygroscopic expansion coefficient, and high adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0248] (Synthesis Example 1) Synthesis of TABP

[0249] 100 ml of N,N-dimethylformamide solution and 200 mmol of trimellitic anhydride chloride (manufactured by Tokyo Chemical Industry Co., Ltd.) were dissolved in a 1 L separable flask, and cooled to 0° C. in an ice bath under a nitrogen atmosphere. Thereafter, at a stirring speed of 100 rpm, a solution of 4,4'-bisphenol dissolved in 50 ml N, N-dimethylformamide and 50 ml pyridine was added dropwise over 2 hours so that the temperature was below 10° C. Stirring was carried out at room temperature for 6 hours. When the dropwise addition started, the solution turned red, and as the dropwise addition ended, a yellow precipitate formed.

[0250] Next, the precipitate was filtered, washed with N,N-dimethylformamide, further washed with water, and filtered twice, and the filtrate was dried to obtain yellow-white crystals containing TABP. Thereafter, heat drying was performed at 130° C. for 2 hours at a temperature increase rate of...

Embodiment 2

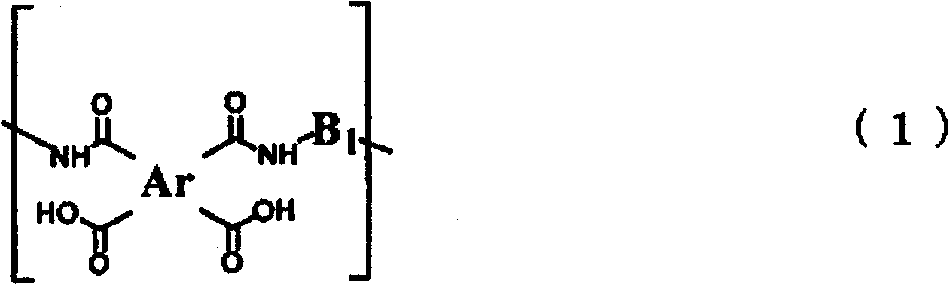

[0267] In a well-dried airtight reaction vessel with a stirrer, add 6.42mmol BPIP, 6.42mmol diamine having an ester structure represented by formula (37) (hereinafter APAB), add 61mL N-methyl-2-pyrrolidone, add the solution to Warm to 80°C to dissolve it. After dissolution, 13.38 mmol of the powder of TABP obtained in Example 1 was slowly added to the solution. By stirring for 30 minutes, the viscosity of the solution increased dramatically. Stirred further 4 hours, obtained transparent, uniform and viscous polyester imide precursor solution, described polyester imide precursor solution has the repeating unit shown in formula (11) and formula (12) The repeating unit, the molar ratio of formula (11) and formula (12) is the ratio of formula (11) / formula (12)=50 / 50. Here, in formula (12), B 2 is a divalent aromatic group represented by formula (16).

[0268] According to the method described in Example 1, a film was formed and imidized to produce a polyester imide film, and t...

Embodiment 3

[0276] In a well-dried airtight reaction vessel with a stirrer, add 8.99mmol BPIP, 3.85mmol APAB, add 63mL N-methyl-2-pyrrolidone, and heat the solution to 80°C to dissolve it. After dissolution, 13.38 mmol of TABP obtained in Example 1 was slowly added to the solution. By stirring for 30 minutes, the viscosity of the solution increased dramatically. Further stirring for 4 hours, a transparent, uniform and viscous polyester imide precursor solution was obtained. The polyester imide precursor solution has a repeating unit shown in general formula (11) and general formula (12) For the repeating unit shown, the molar ratio of general formula (11) to general formula (12) is the ratio of general formula (11) / general formula (12)=70 / 30. Here, in general formula (12), B 2 is a divalent aromatic group represented by formula (16).

[0277] According to the method described in Example 1, a film was formed and imidized to produce a polyester imide film, and the physical properties wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap