Method for determining dead zone of valve

A dead zone, control valve technology, applied in drilling equipment and methods, earthwork drilling, automatic control systems for drilling, etc., can solve problems such as changes and infeasibility, and achieve the effect of eliminating dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

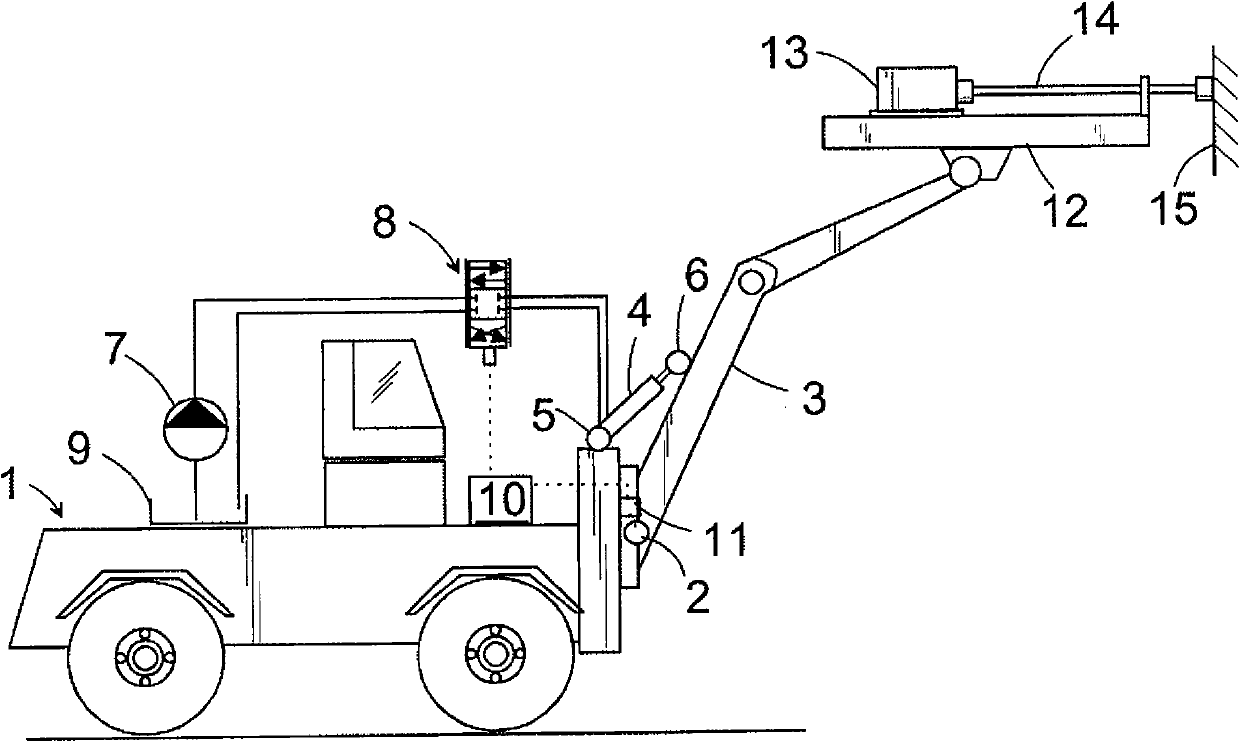

[0025] figure 1 An actuator in a rock drilling rig is schematically shown. Reference numeral 1 schematically denotes a base to which a drill arm 3 is rotatably connected via a joint 2 . The drill arm 3 is rotatable about the axis of the joint 2 by means of an actuator (i.e. a hydraulic cylinder 4), one end of which is connected to the base 1 by means of a joint 5 and the other end is correspondingly rotatably connected to the drill arm by means of a joint 6 3. To control the hydraulic cylinder 4 , pressure medium from the pump 7 can be fed to the hydraulic cylinder via a proportional control valve 8 , whereby pressurized fluid also flows from the other end of the hydraulic cylinder 4 into a pressurized fluid container 9 via the valve 8 . To control the hydraulic cylinder 4, a proportional control valve is controlled by a control unit 10, to which a sensor 11 representing the angle of rotation of the boom is also connected. Additionally, the figures show a feed beam 12 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com