Mixing device for regulating density of drilling liquid

A drilling fluid density and mixing device technology, applied in mixers, mixing methods, fluid mixers, etc., can solve the problems of poor mixing effect of static mixers, easy formation of natural gas hydrates, and stratification of mixed drilling fluids. Good mixing effect, particle size reduction, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

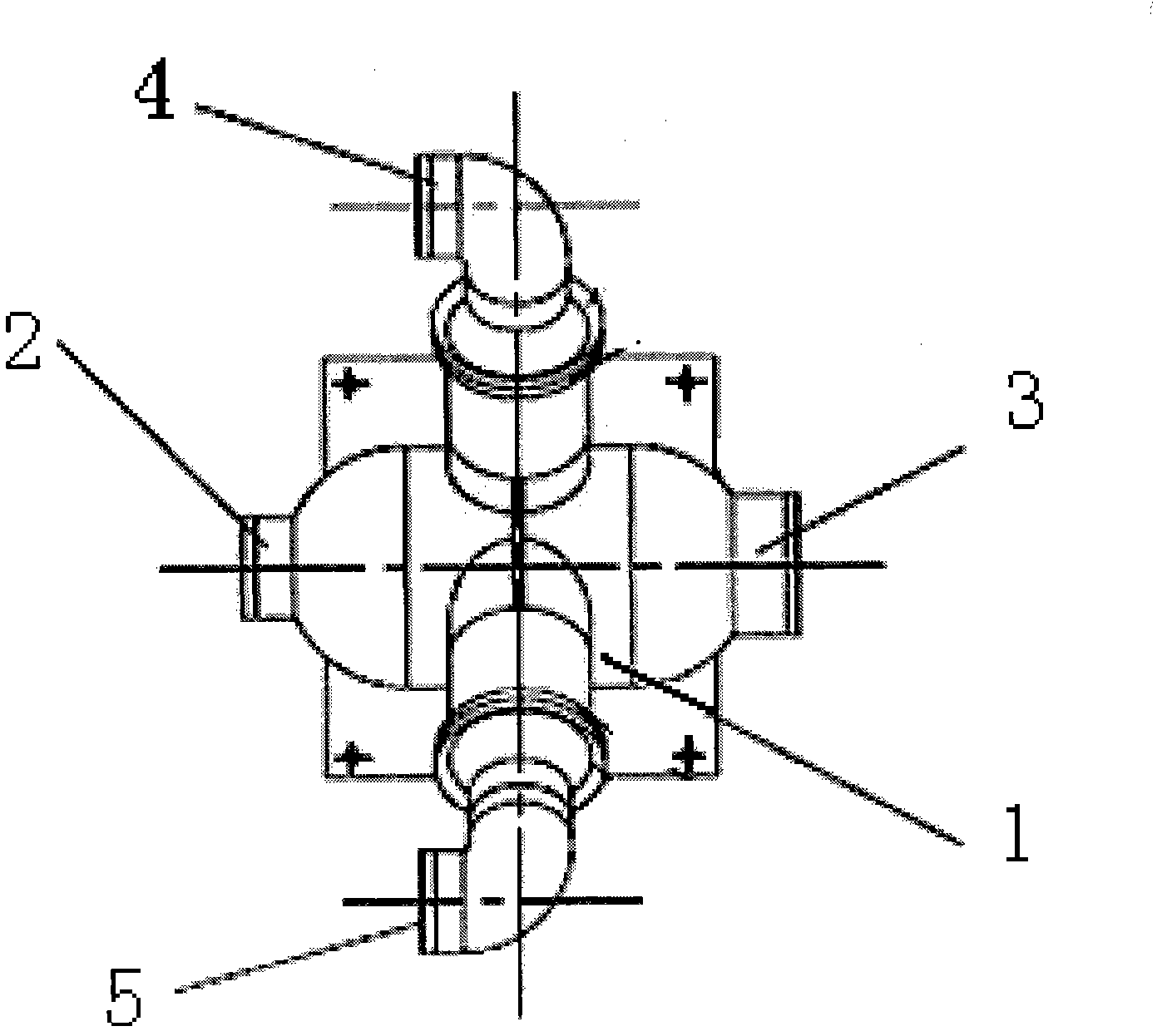

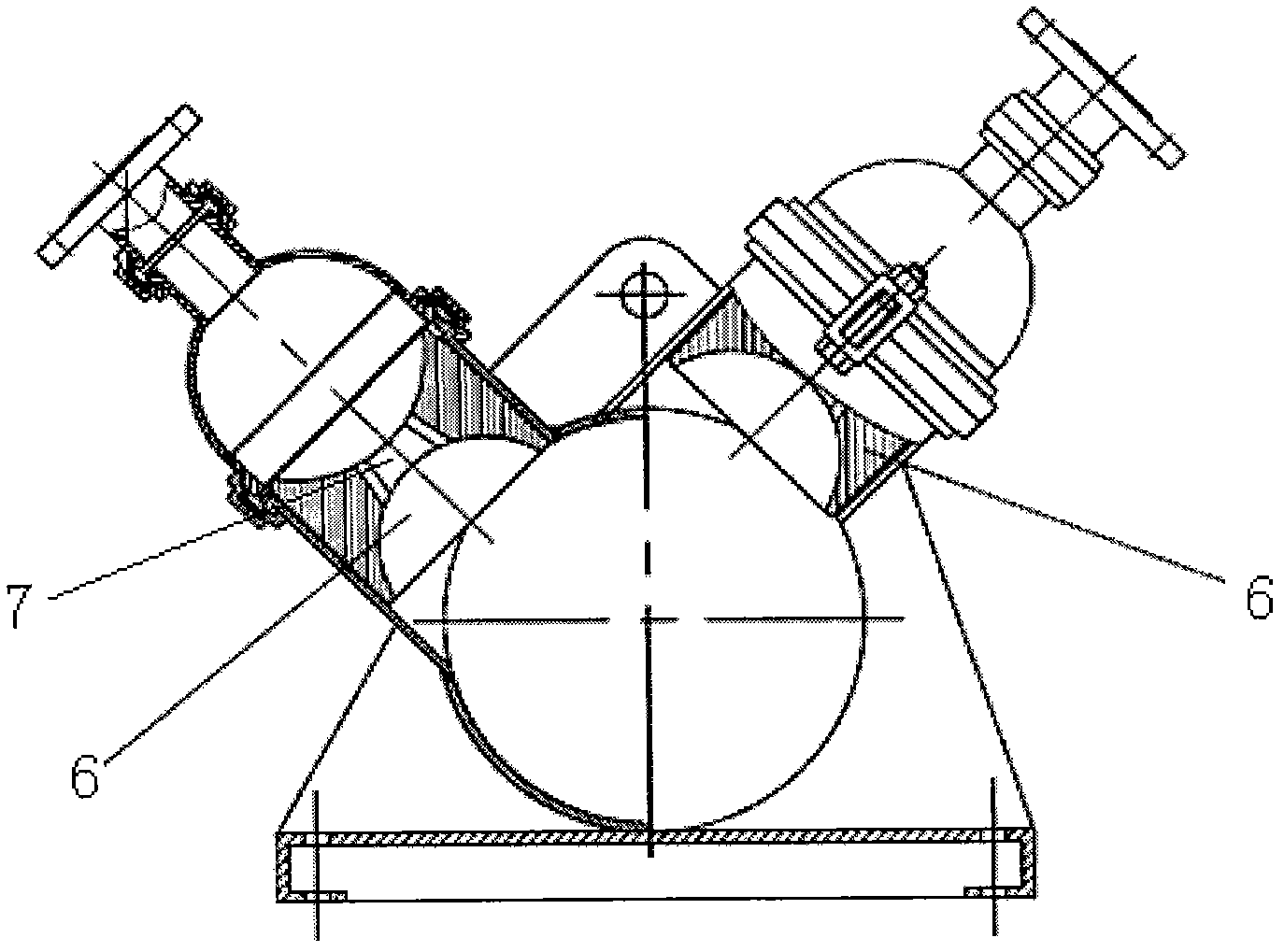

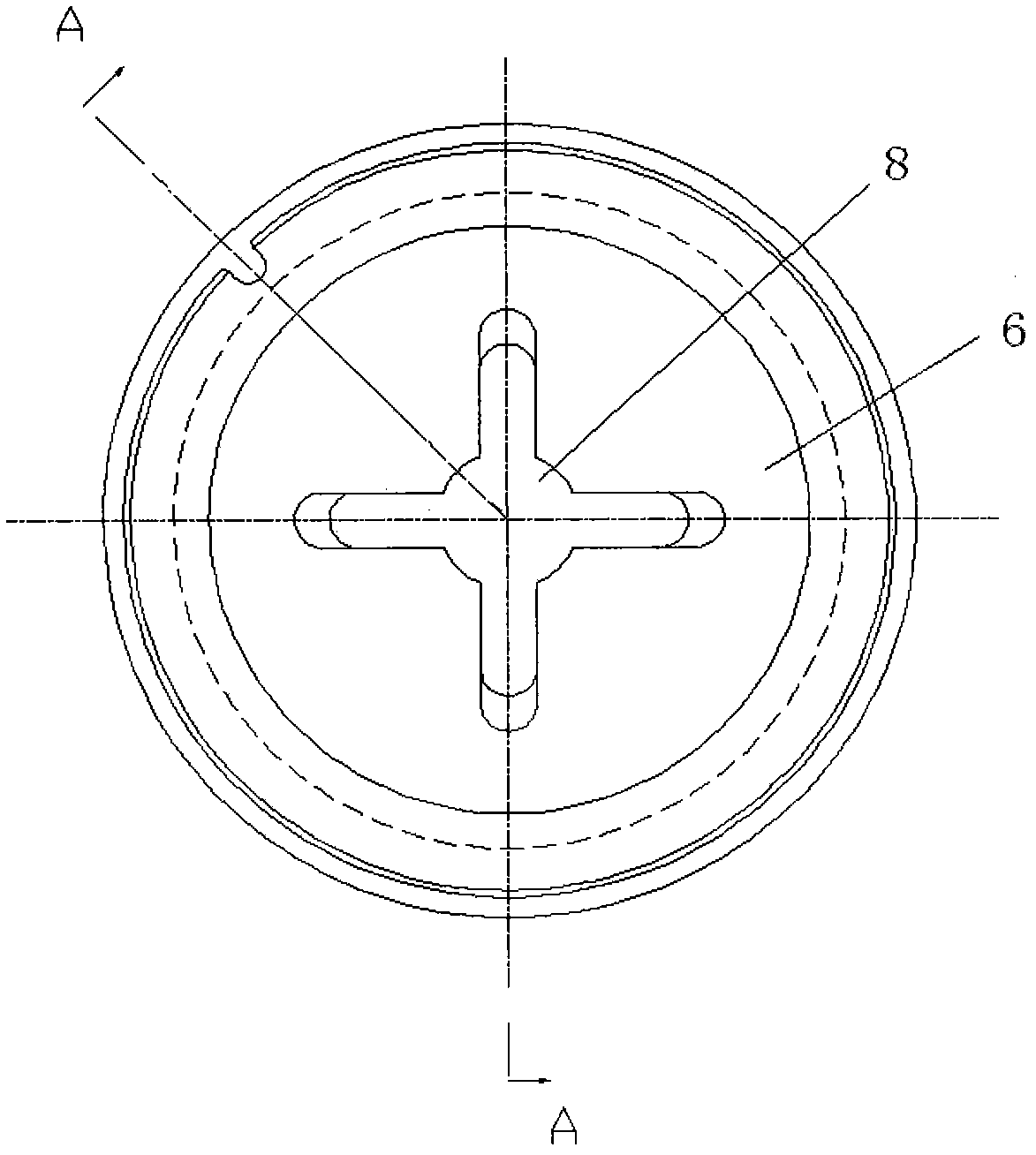

[0018] Such as figure 1 , figure 2 As shown, the present invention comprises a tubular mixing device body 1, one end of the mixing device body 1 is provided with a drilling fluid inlet 2, and the other end is provided with a mixed fluid outlet 3, and the circumference of the mixing device body 1 is provided with a high-density drilling fluid inlet 4 and a seawater inlet 5, the high-density drilling fluid inlet 4 and the seawater inlet 5 are respectively connected to the mixing device body 1 through an interface 6, and the center of each interface 6 is provided with a short throat 7, each throat Install a nozzle 8 in 7 (as image 3 , Figure 4 shown), the length of the throat can be determined as required.

[0019] In the above-mentioned embodiment, the cross-section of each nozzle 8 is in the shape of a plum blossom, and the number of plum blosso...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap