Iron-based composite absorbing agent and preparation method thereof

A composite adsorption, iron-based technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of small adsorption capacity and achieve the effect of high fluorine adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above iron-based composite adsorbent. In a preferred embodiment, the method includes the following steps:

[0041] (1) Prepare an aqueous solution of polyvinyl alcohol;

[0042] (2) Add iron salt or iron salt solution to the aqueous solution obtained in step (1) at room temperature, dissolve and stir evenly, to obtain an iron salt polyvinyl alcohol aqueous solution;

[0043] (3) Under the condition of stirring, add an alkali solution to the iron salt polyvinyl alcohol aqueous solution obtained in step (2) until the pH of the solution is about 6.5 to about 11.0, and then stir for a period of time;

[0044] (4) While stirring, continue to add other metal salt solutions, and then add alkali solution until the pH of the solution is about 5.0 to about 8.0, and then stir for a period of time, wherein the other metals are selected from lanthanide rare earth metals and zirconium (Zr ) At least one of;

[0045] (5) The precip...

Embodiment 1

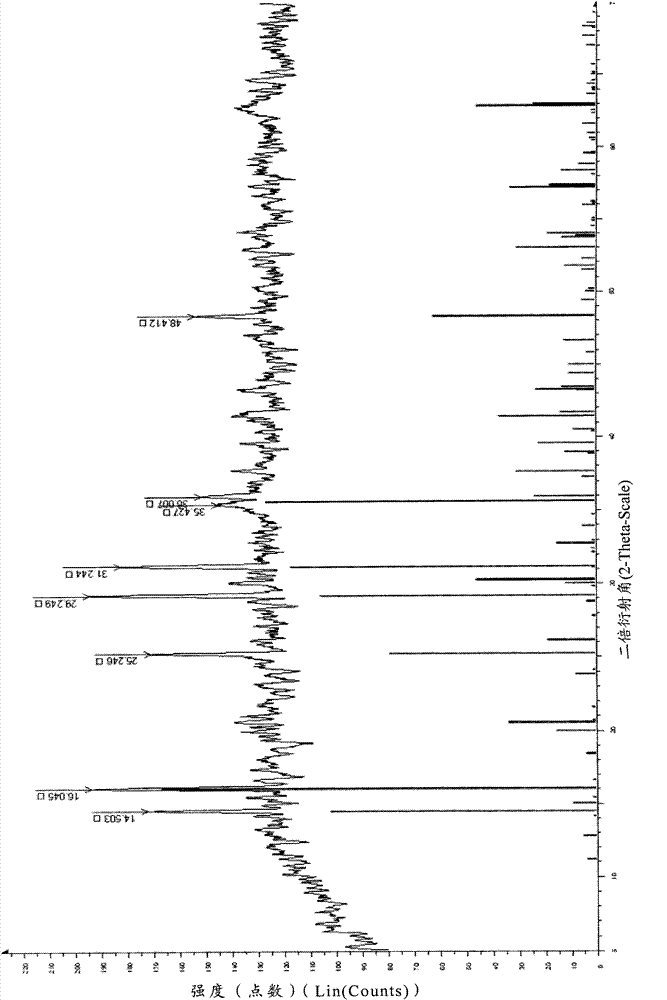

[0068] Example 1 Preparation of adsorbent

[0069] Weigh 50 grams of PVA-1750, add 600 milliliters of deionized water to swell for 6 hours, and then heat under mechanical stirring and maintain a constant temperature of 90°C. After 3 hours, all PVA is dissolved. The PVA solution was cooled and the volume was adjusted to 1000 ml to obtain a 5% PVA-1750 stock solution. Mix 64ml of 1M ferric chloride solution with 32ml of 1M ferrous sulfate solution at room temperature, add 4ml of PVA stock solution and stir evenly to prepare 100ml of 0.96M iron salt mixed solution containing 0.2% (wt / v) PVA-1750; In this case, add 5M sodium hydroxide solution to the solution, and measure the pH value of the solution in real time with a digital display pH meter. As the amount of sodium hydroxide added increases, precipitation begins to occur. Continue to add sodium hydroxide solution and the pH rises until the mixed solution is precipitated When the pH is 9.0, stop adding sodium hydroxide solution a...

Embodiment 2

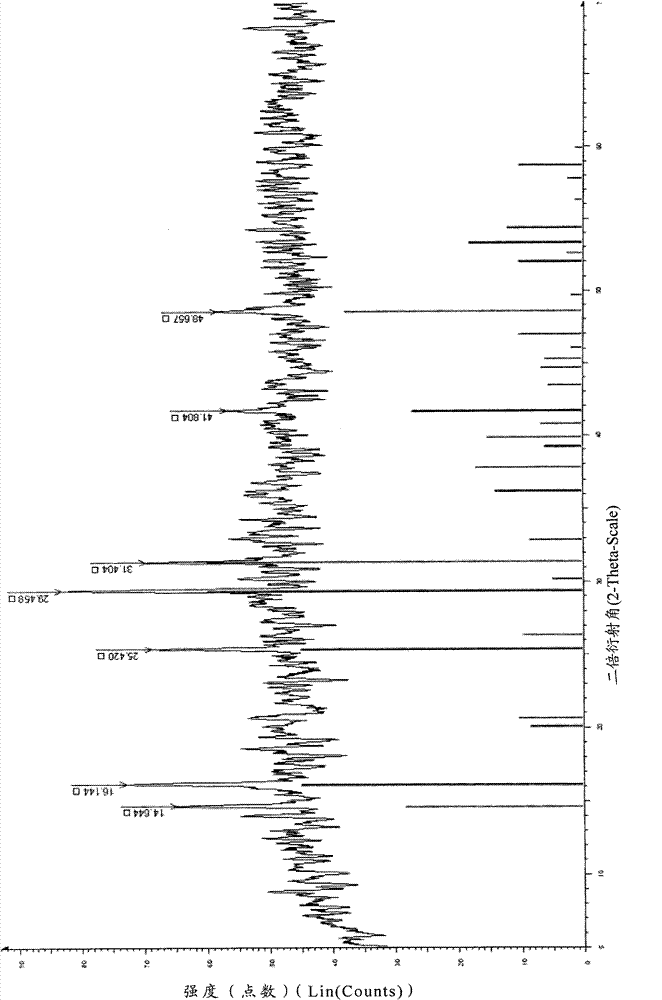

[0070] Example 2 Preparation of adsorbent

[0071] Similar to Example 1, mix 64ml of 1M ferric sulfate solution with 32ml of 1M ferrous sulfate solution at room temperature, add 4ml of PVA-1750 stock solution and stir evenly to prepare 0.96M iron salt containing 0.2% (wt / v) PVA Mixed solution 100ml; add 5M sodium hydroxide solution to the solution under stirring, and measure the pH value of the solution in real time with a digital display pH meter. As the amount of sodium hydroxide added increases, precipitation begins to occur, continue to add sodium hydroxide solution, pH Rise until the pH of the precipitation mixture is 9.0, stop adding sodium hydroxide solution, continue to stir the suspension for 10 minutes; then add 50ml of 0.5M cerium sulfate solution to the suspension, and add a small amount of sodium hydroxide under stirring Solution, adjust the pH value of the suspension to 5.9, continue to stir the suspension for 30 minutes; centrifuge the above suspension at 4000 rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com