Catalyst for producing fuel oil

A technology for producing catalysts for fuel oil, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of low catalyst efficiency and poor pertinence, and achieve easy mastery of production technology and low equipment investment. Small, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

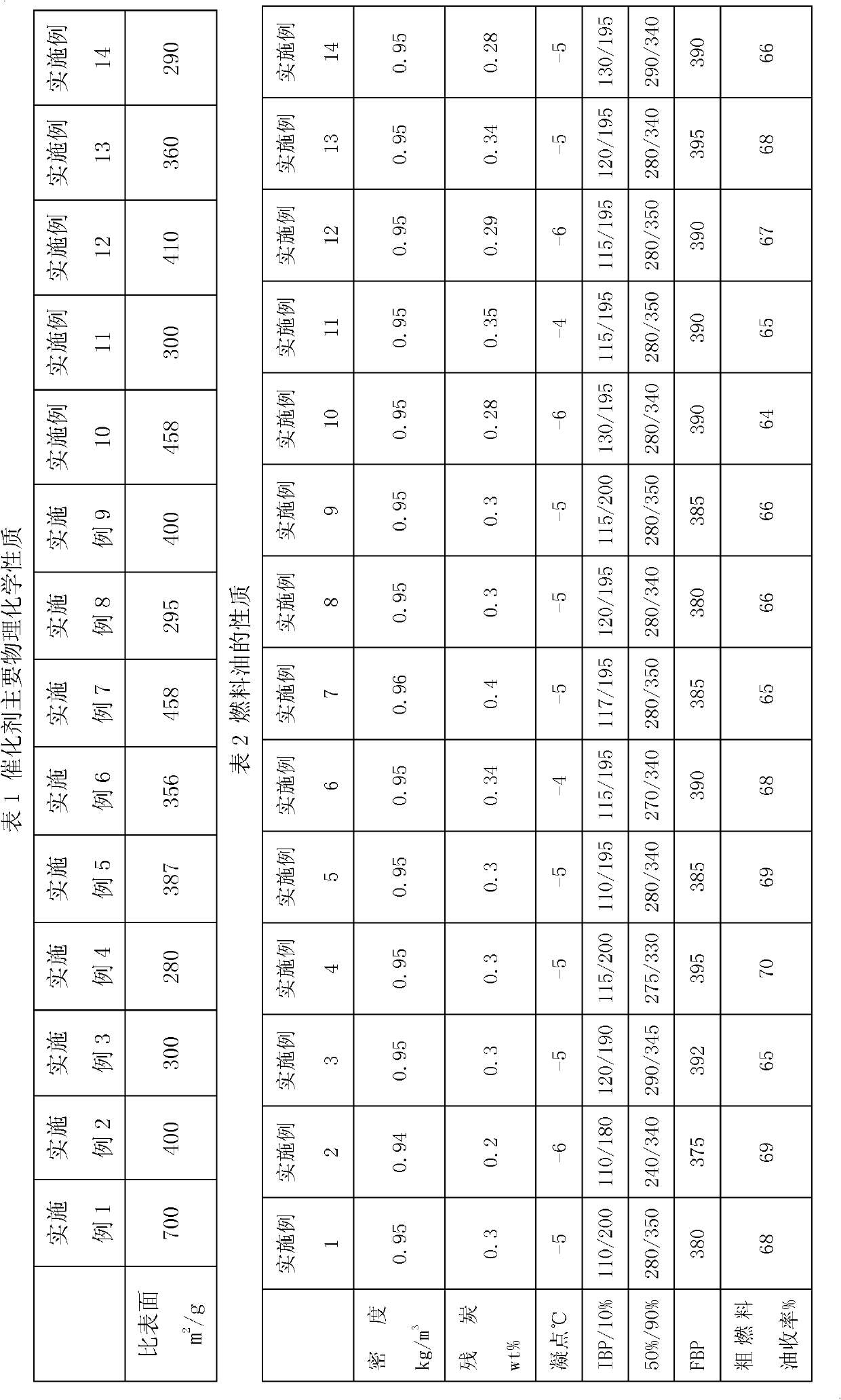

Embodiment 1

[0028]Catalyst component: 50g of Y-type molecular sieve, 30ml of aqueous solution containing 0.8g of potassium bromide;

[0029] Preparation method: Immerse Y-type molecular sieve (produced by Wuxi Rongdeli Molecular Sieve Factory) with potassium bromide aqueous solution for 2 hours, and dry at 120°C for 2 hours to obtain a catalyst. The properties are shown in Table 1;

[0030] Potassium bromide in the catalyst is 1.21% of the weight of the catalyst in terms of bromine.

[0031] Utilize above-mentioned catalyzer to carry out the method for intermittent coal tar preparation fuel oil:

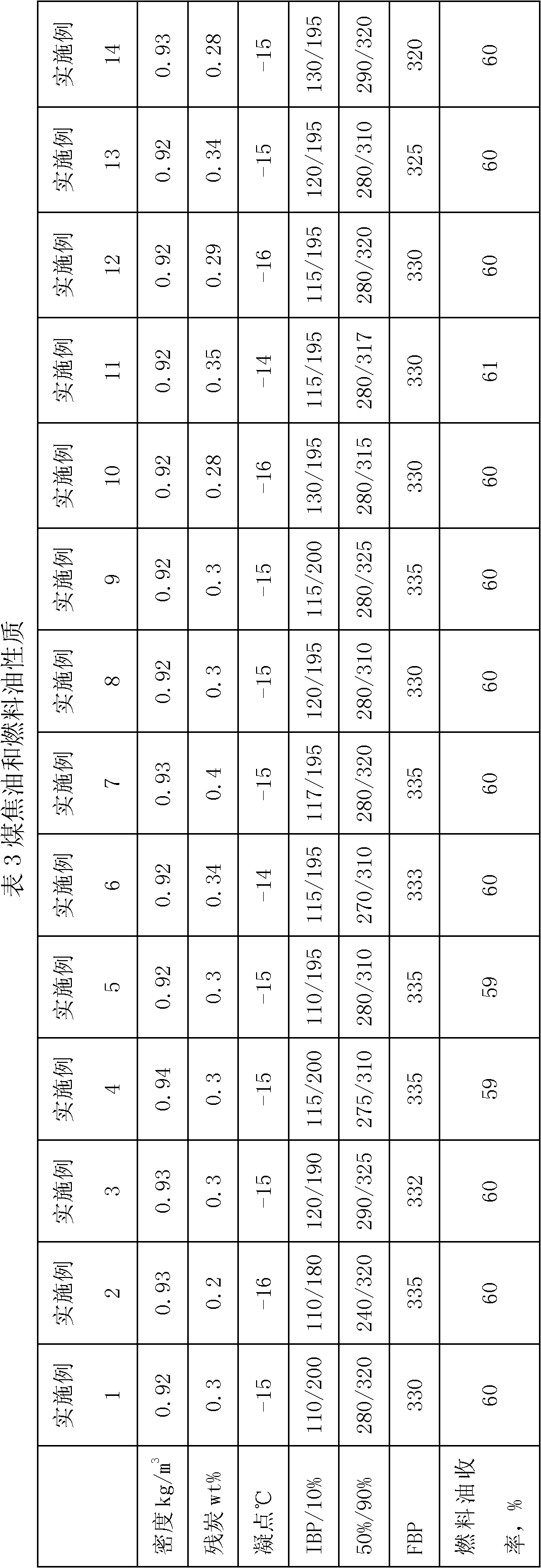

[0032] Add 300g of coal tar with a water content of 1wt% to the 1000ml autoclave device, and then add 4.5g of catalyst. After the autoclave is sealed, heat the autoclave to raise the temperature to 350°C, keep the temperature for 5 minutes, and then drop to room temperature Finally, the reaction product is taken out from the reactor, and then separated by distillation, and the fraction at 80-28...

Embodiment 2

[0036] Catalyst component: 50g of ZSM-5 molecular sieve, 25ml of aqueous solution containing 0.8g of potassium bromide;

[0037] Preparation method: ZSM-5 molecular sieve (produced by Zichuan Fenghuang Fine Chemical Co., Ltd., Zibo City) was impregnated with an aqueous solution of potassium bromide for 2 hours, and dried at a temperature of 120°C for 2 hours to obtain a catalyst. The properties are shown in Table 1;

[0038] Potassium bromide in the catalyst is 1.21% of the weight of the catalyst in terms of bromine.

[0039] Utilize above-mentioned catalyzer to carry out the method for intermittent coal tar preparation fuel oil:

[0040] Add 300g of coal tar with a moisture content of 0.1wt% to the 1000ml autoclave device, and then add 4.5g of catalyst. After the reactor is sealed, heat the reactor to raise the temperature to 360°C, keep the temperature for 10 minutes, and then drop to room temperature Finally, the reaction product is taken out from the reactor, and then sep...

Embodiment 3

[0044] Catalyst component: γ-Al 2 o 3 50g 30ml of aqueous solution containing 1.0g of potassium bromide;

[0045] Preparation method: γ-Al 2 o 3 Immerse it in an aqueous solution of potassium bromide for 2 hours, and dry it for 1 hour at a temperature of 120°C to obtain a catalyst whose properties are shown in Table 1;

[0046] Potassium bromide in the catalyst is 1.66% of the weight of the catalyst in terms of bromine.

[0047] Utilize above-mentioned catalyzer to carry out the method for intermittent coal tar preparation fuel oil:

[0048] Add 300g of coal tar with a water content of 1.8wt% to the 1000ml autoclave device, and then add 4.5g of catalyst. After the reactor is sealed, heat the reactor to raise the temperature to 350°C, keep the temperature for 15 minutes, and then drop to room temperature Finally, the reaction product is taken out from the reactor, and then separated by distillation, and the fraction at 80-280° C. is taken to obtain fuel oil;

[0049] Util...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap