Automatic spot welding machine

A spot welding machine and automatic technology, applied in welding equipment, resistance welding equipment, electrode characteristics, etc., can solve problems such as poor welding quality, unstable welding, and low solder joints, and achieve time saving, cost reduction, and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

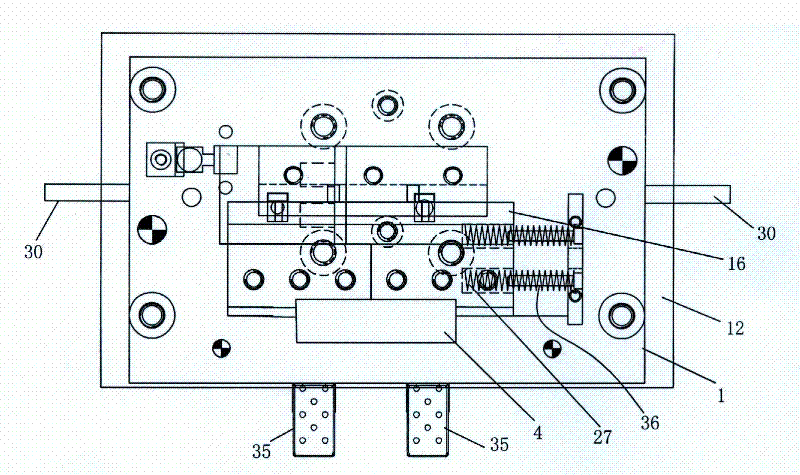

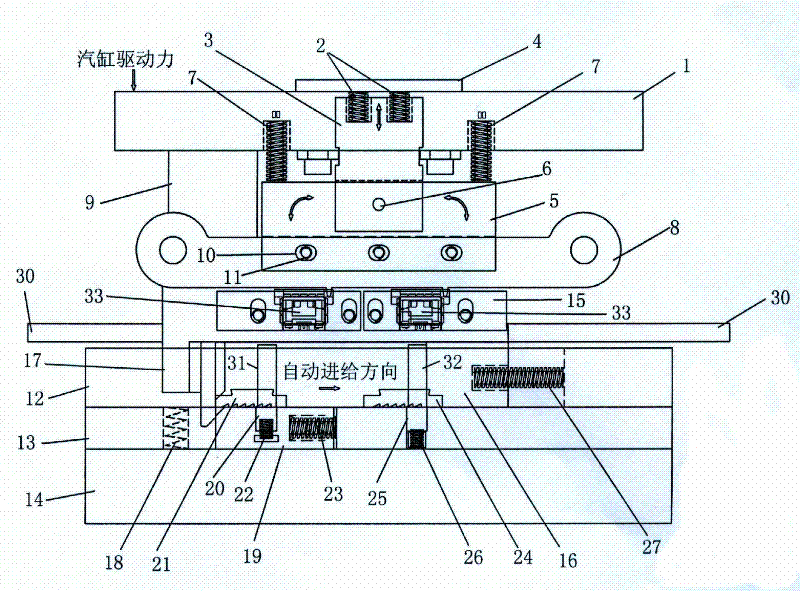

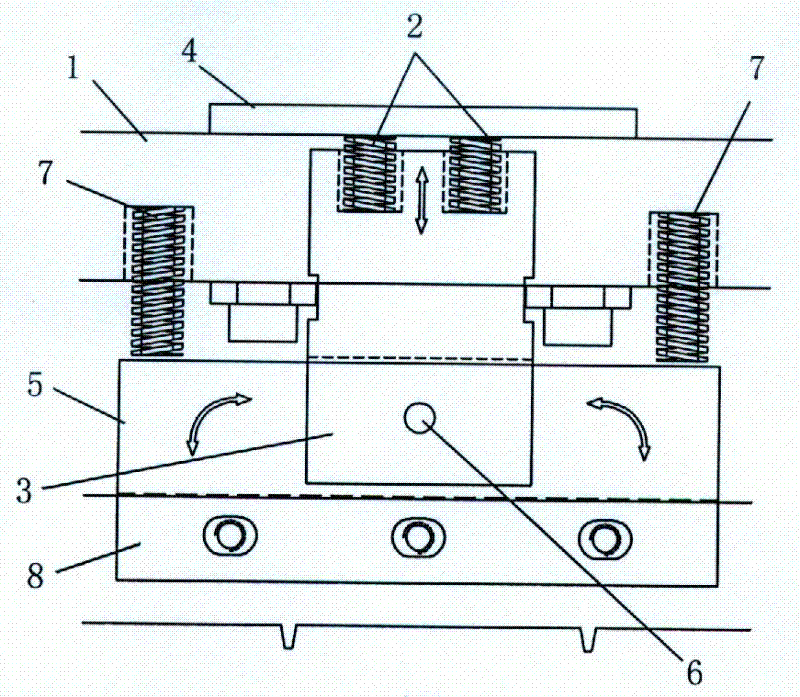

[0049] Below, in conjunction with the accompanying drawings, the specific implementation manners of the present invention will be introduced.

[0050] Such as Figure 1 to Figure 5 As shown, the automatic spot welding machine of the present invention comprises a cylinder, an upper electrode and a lower electrode, the cylinder drives the upper electrode, and the upper electrode and the lower electrode constitute the welder head of the automatic spot welding machine;

[0051] The upper electrode includes an upper die base 1 positioned on the top of the welding head, an automatic weight reduction device, a swing bar balance device and an upper welding head 8, and the automatic weight reduction device is configured with the upper die base 1 and connected with the swing rod balance device. The head 8 is arranged at the lower part of the pendulum balance device, and its position relative to the pendulum balance device can be adjusted forward and backward along the feed direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com