Cutting process for Z surface X-direction angle control of Z plate seed crystal blocks

A technology of cutting process and angle control, which is applied in the field of Z-plane X-direction angle control cutting process of Z-plate seed crystal blocks, and can solve the problems of increased inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

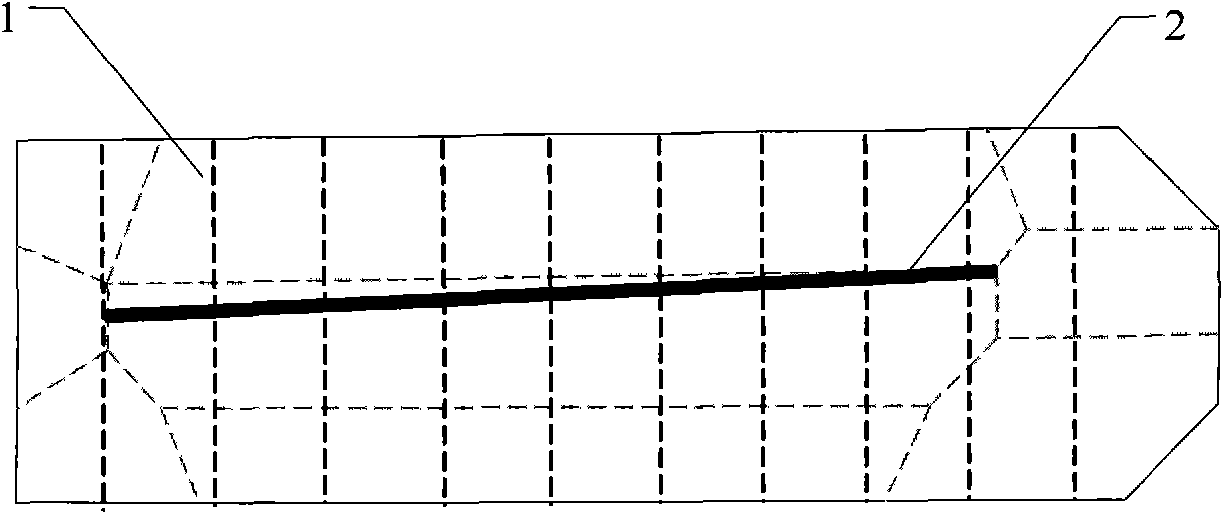

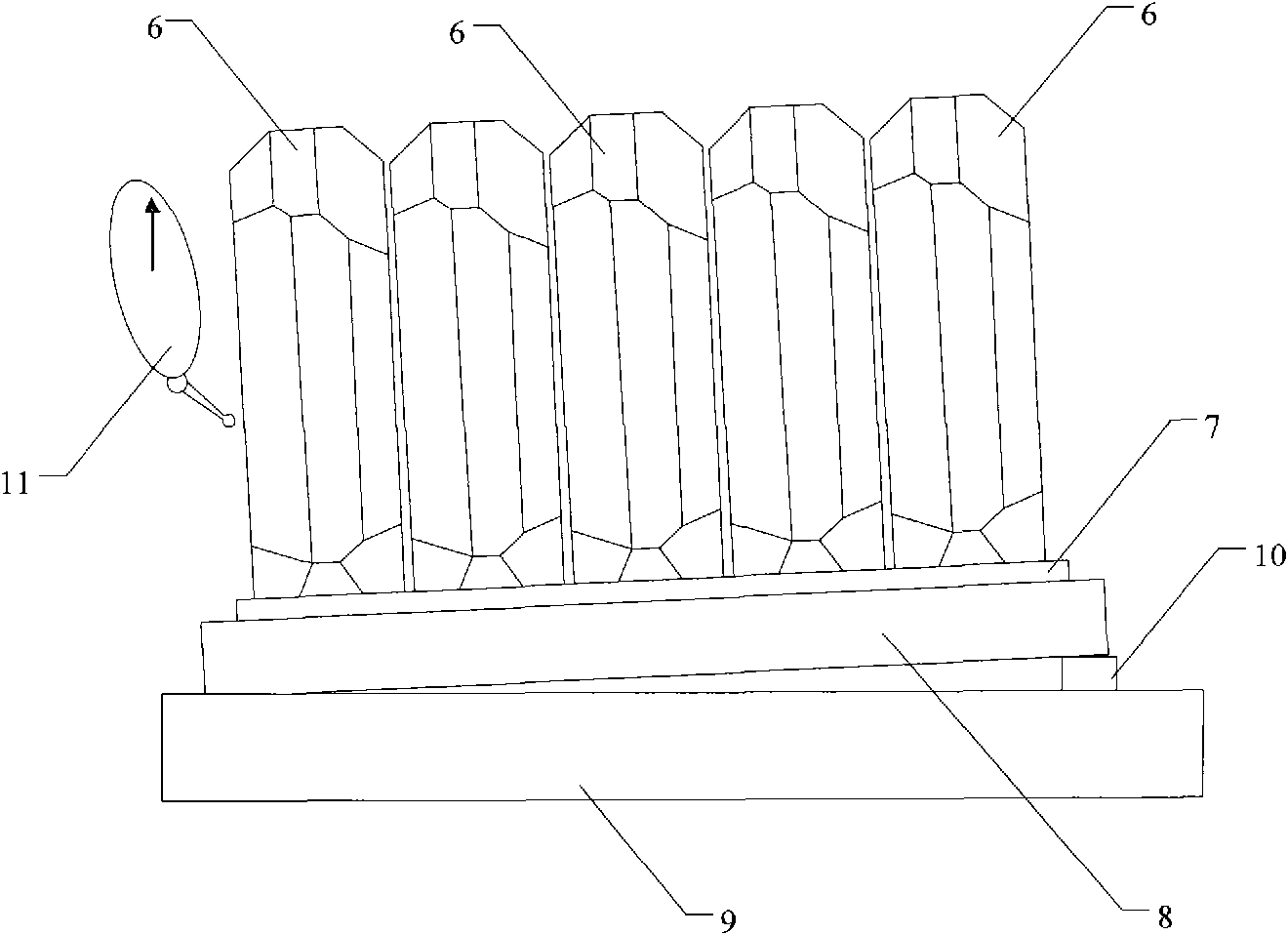

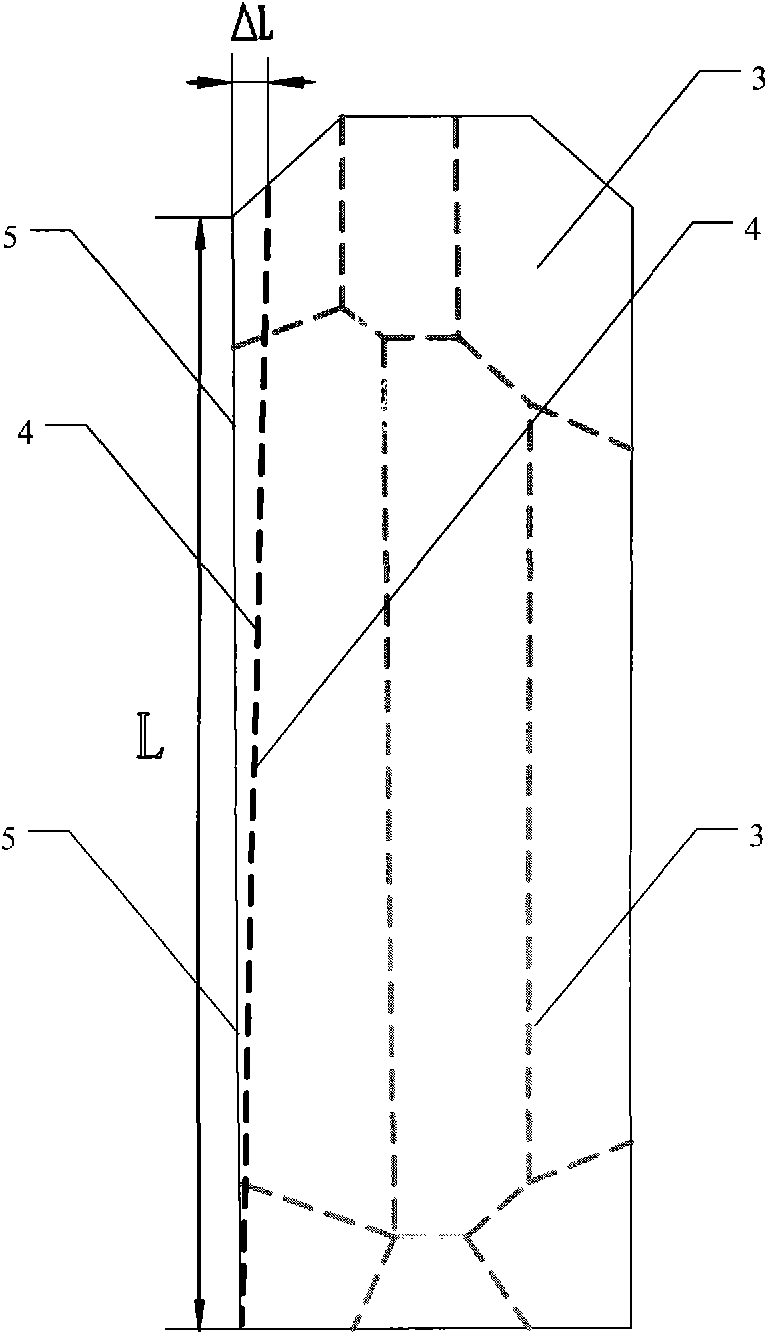

[0016] Such as figure 2 As shown, a Z-plate seed block Z-plane X-direction angle control cutting process, it comprises the following steps:

[0017] Step 1. Process and orient the Z surface of the Z-plate seed crystal block, and measure the X-direction angular difference of the Z-surface Z-surface of the Z-plate seed crystal block. The processing needs to control the X-direction angle difference of the Z-surface of all Z-plate seed crystal blocks within ±5′ within;

[0018] Step 2. Sorting the Z-plate seed blocks inclined in one direction, and classifying the Z-plane X-direction angle difference of the Z-plate seed blocks according to the difference ±1′;

[0019] Step 3. Glue the same Z-plate seed crystal to the board to obtain the sticky body of the seed crystal; when gluing the plate, the Z-surface of the Z-plate seed crystal is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com