Multifunctional color hot stamping machine applicable to curved surface package container

A packaging container, multi-functional technology, applied in printing presses, rotary presses, printing and other directions, to achieve the effect of improving production efficiency, saving equipment floor space and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

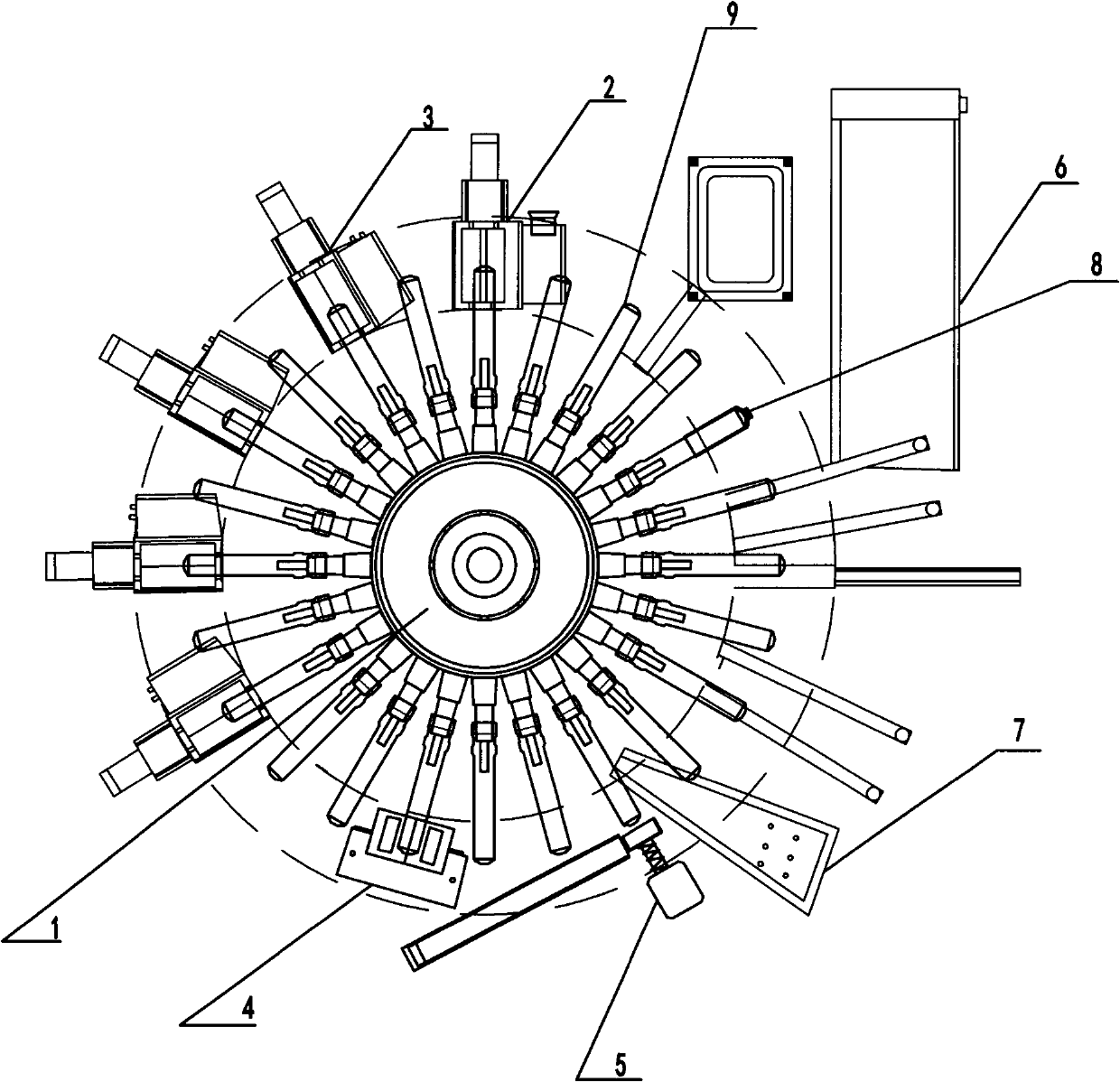

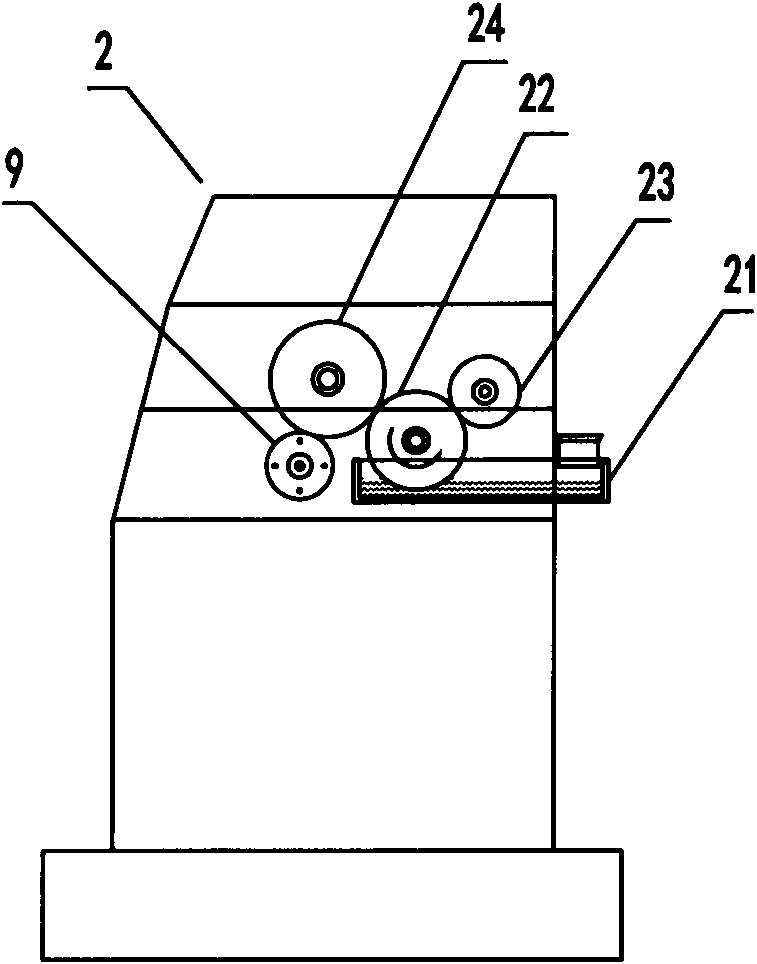

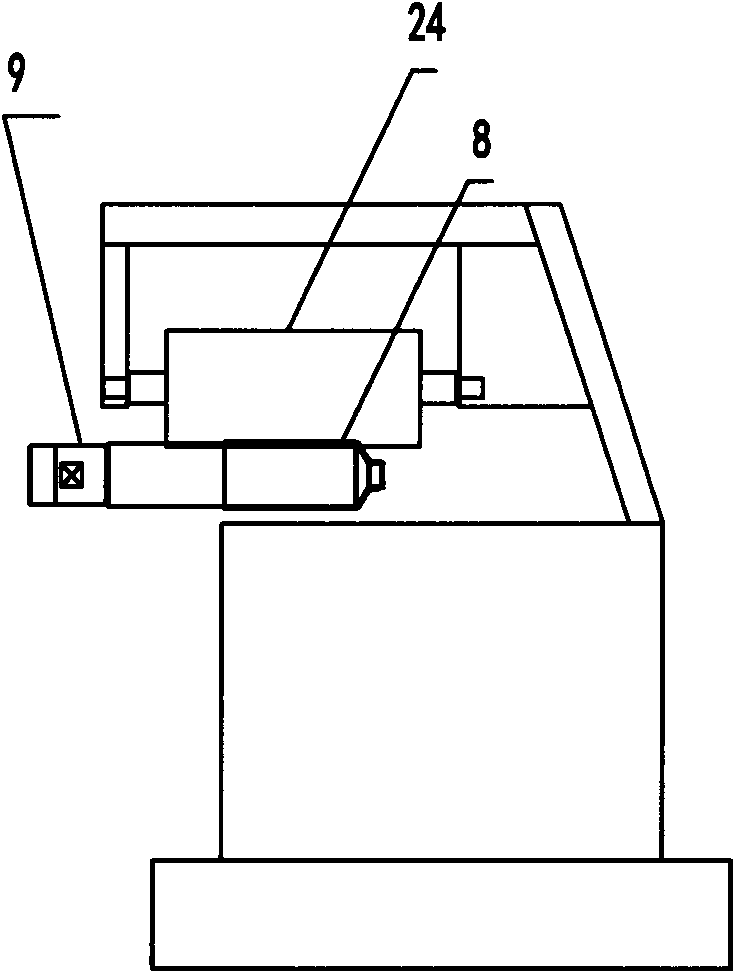

[0015] see figure 1 , The color hot stamping machine of this embodiment includes a turntable 1, a glazing unit 2, a printing unit 3, a hot stamping unit 4, an upper cover unit 5, a feeding conveying and propulsion device 6, and an unloading conveying device 7. The turntable 1 is arranged horizontally. Several radial mandrels 9 are installed on the circumference of the turntable 1. The mandrel 9 is composed of a mandrel seat and a mandrel shaft. The two are connected by a ball bearing. The mandrel The seat is fixed on the turntable 1, the mandrel shaft is connected with the servo motor through the transmission mechanism, and the motor drives the mandrel 9 to rotate. The workpiece to be decorated, such as the curved surface packaging container 8 in this embodiment, is sleeved on the mandrel 9, and the mandrel 9 is provided with small holes and air passages to communicate with the pre-blowing device. When the curved surface packaging container 8 is in each decoration operation I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com