Bending machine for spiral light tube

A technology of bending machine and lamp tube, applied in glass reshaping, glass manufacturing equipment, glass molding, etc., can solve the problems of high production cost, unstable shape, low efficiency and other problems of exposed tube manufacturers, and achieve product shape The effect of stability, high pass rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following best examples of the spiral lamp tube bending machine of the present invention do not limit the protection scope of the present invention.

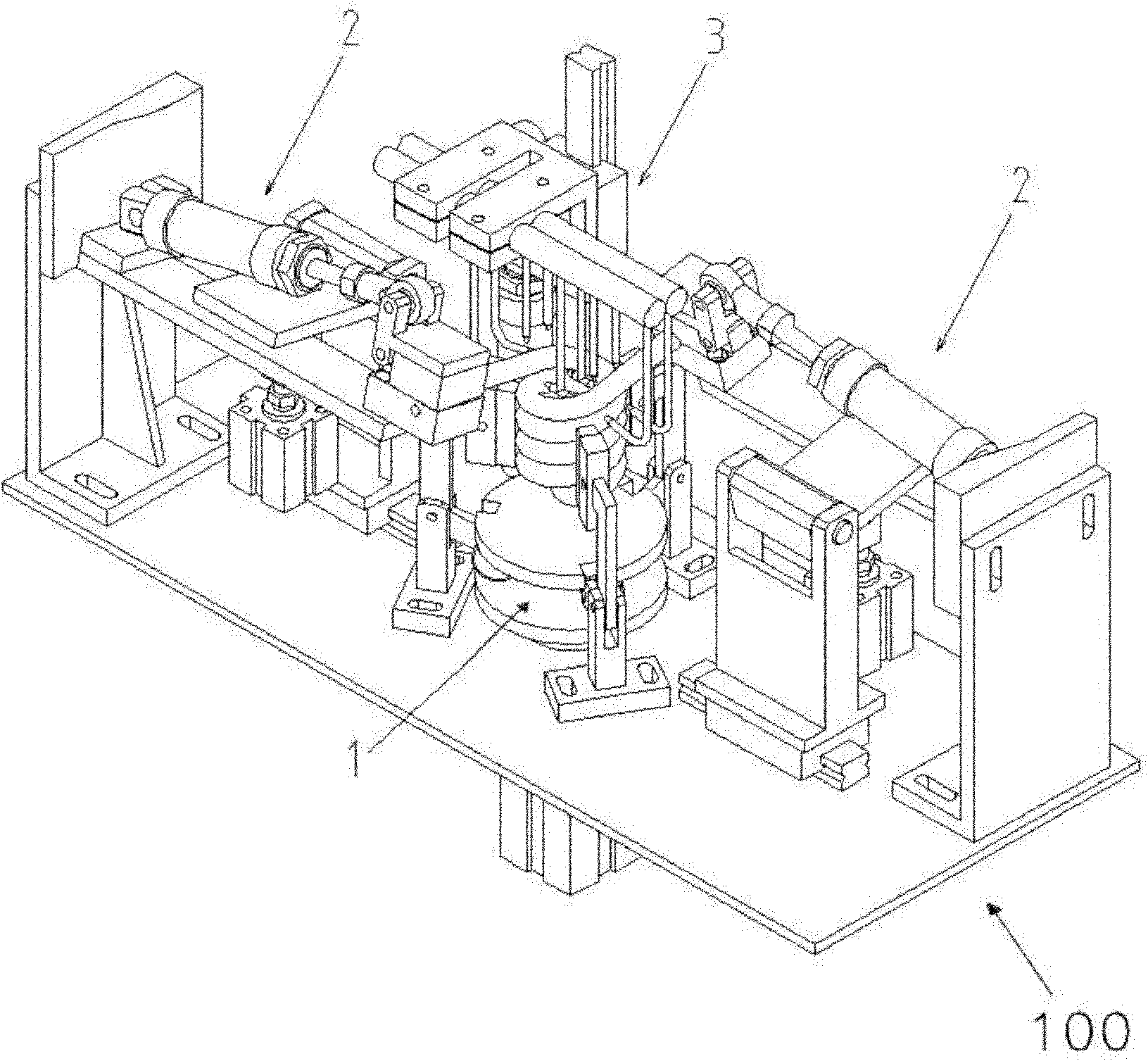

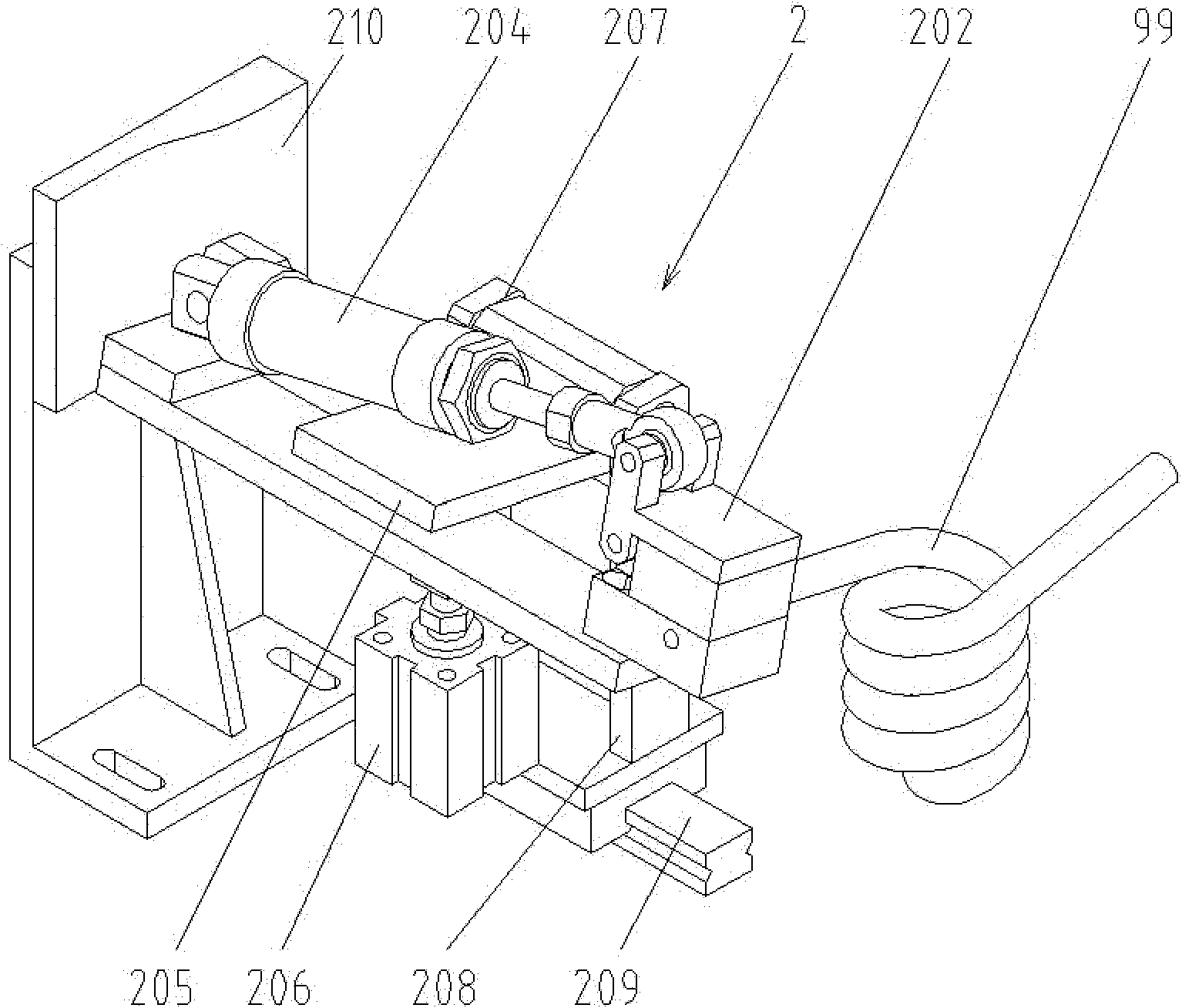

[0013] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , provides a spiral lamp tube bending machine, including a frame 100, and also includes a lamp tube clamping mechanism 1 installed on the frame 100, and two sides of the lamp tube clamping mechanism 1 are respectively provided with a bending pin to execute A flame heating system 3 is arranged above the mechanism 2 and the lamp clamping mechanism 1 .

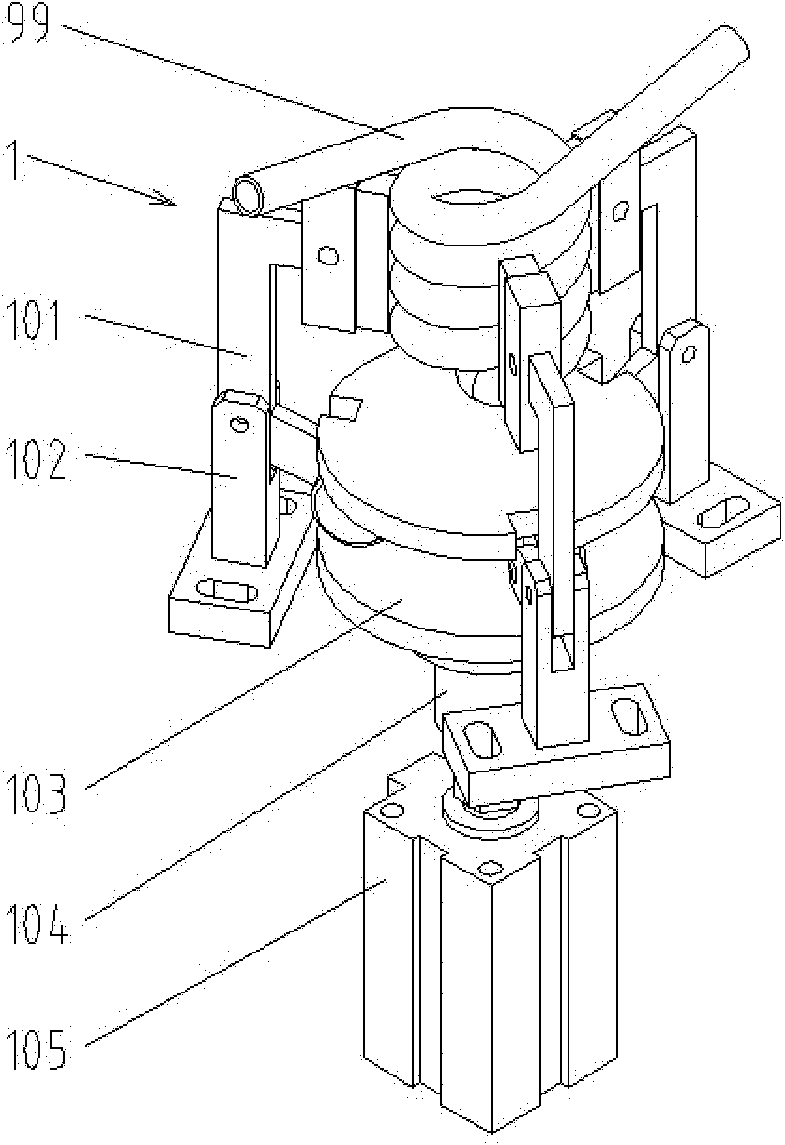

[0014] The lamp clamping mechanism 1 is arranged in the middle of the frame 100, and includes a drive cylinder 105 installed on the frame 100, a push plate 103 rotatably connected with the drive cylinder 105, and a linear bearing is installed on the shaft of the push plate 103. 104. There are three jaws 101 distributed at an angle of 120 degrees in the circumferential direction of the push plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com